Preparation method and mould of liquid-solid composite forming copper cladding aluminum bus duct platoon blank

A copper-clad aluminum strip and composite forming technology, which is used in the manufacture of cables/conductors, rods/bars/wires/strip conductors, electrical components, etc. problems such as low rate, cladding and core material breakage, etc., to achieve the effect of simple production conditions, simple structure, and reduced times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

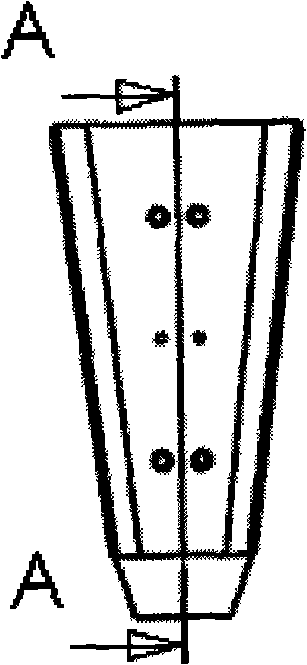

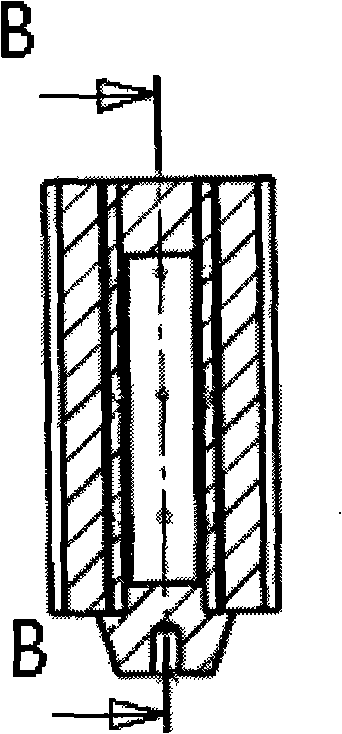

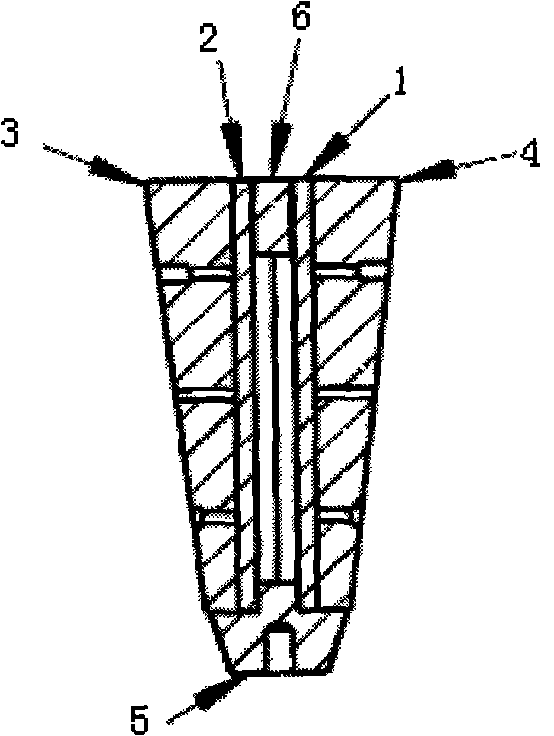

[0011] Example 1: As shown in the figure, a mold for liquid-solid composite forming copper-clad aluminum bar busway blank consists of two half-moulds, namely half-mould I3 and half-mould II4, the half-moulds are inverted trapezoidal, and the mold type The cross-sectional shape of the cavity is a special-shaped structure, and the special-shaped structure is a rectangle in the middle, and the two sides are connected by arcs. There is an ejector 5 under the half-mold I 3 and half-mold II 4, and the upper part of the two half-mold cavities has a punch. 6.

[0012] Preparation before squeeze casting: pre-treat the copper pipe to remove oil stains (degreasing-cleaning-neutralization-cleaning-passivation-cleaning-drying), and preheat the squeeze casting mold to 100°C. At the same time, the aluminum alloy is smelted, refined at 680°C, and left to stand for 30 minutes.

[0013] Squeeze casting: figure 1 Lift the punch 6 in the mold shown, put a 60mm long, 20mm wide copper tube with a...

example 2

[0015] Example 2: As shown in the figure, a mold for liquid-solid composite forming copper-clad aluminum bar busway blank consists of two half-moulds, namely half-mould I3 and half-mould II4, and the half-moulds are in an inverted trapezoidal shape. The cross-sectional shape of the cavity is a special-shaped structure, and the special-shaped structure is a rectangle in the middle, and the two sides are connected by arcs. There is an ejector 5 under the half-mould I3 and half-mould II4, and the upper part of the two half-moulds has a punch 6.

[0016] Preparation before squeeze casting: pre-treat the copper pipe to remove oil stains (degreasing-cleaning-neutralization-cleaning-passivation-cleaning-drying), and preheat the squeeze casting mold to 450°C. At the same time, the aluminum alloy is smelted, refined at 750°C, and left to stand for 30 minutes.

[0017] Squeeze casting: figure 1 Lift the punch 6 in the mold shown, put the special-shaped copper pipe with a length of 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com