Method for improving quality of direct reduced iron by rotary hearth furnace

A technology for reducing iron and rotary hearth furnace, applied in the field of iron and steel smelting, can solve the problems of high gangue and sulfur content, low density, low grade, etc., and achieve the effects of cost saving, less metal loss and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

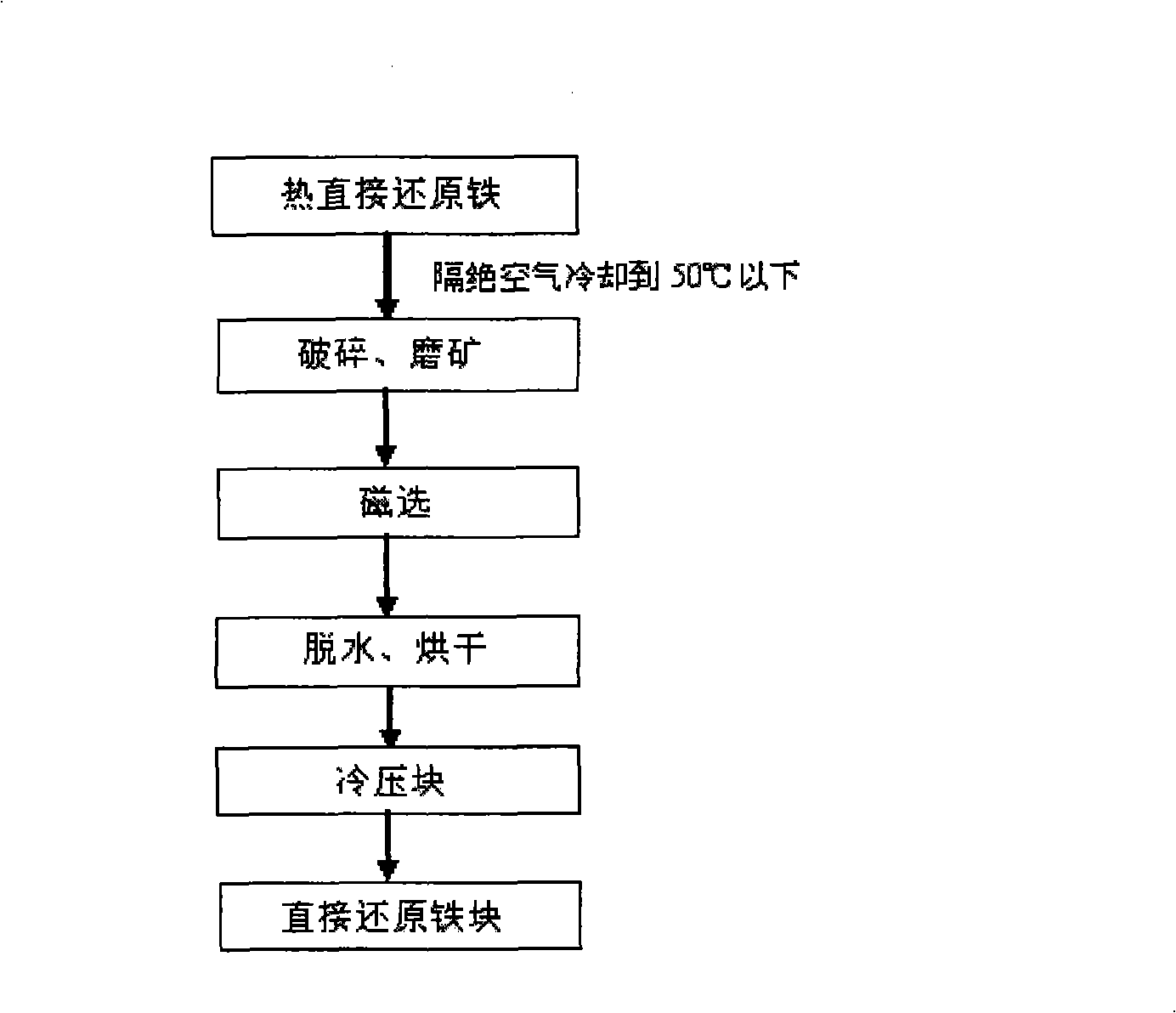

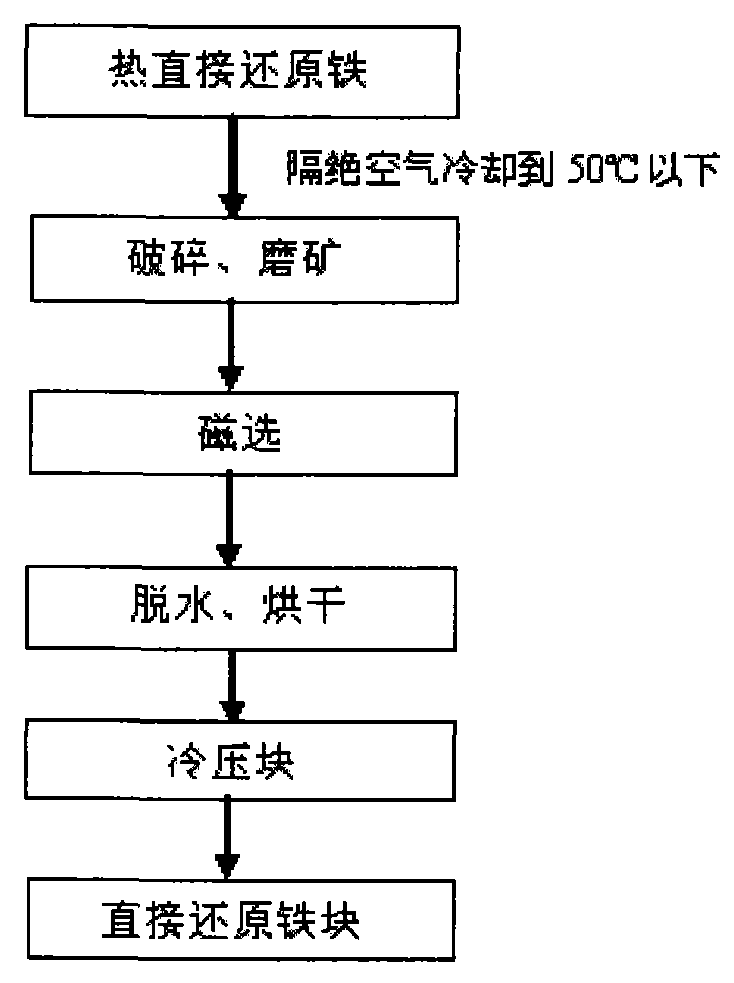

Method used

Image

Examples

Embodiment 1

[0021] A. Rotary hearth furnace direct reduced iron: TFe content is 62.41%, SiO 2 Iron ore concentrate with a content of 7.31% is used as raw material, and a mass ratio of 24% coal powder and 3% bentonite is added. The RZD-105-14 / 16 rotary hearth furnace experimental device of the prior art is used. Under the production process and technical conditions of the rotary hearth furnace, direct reduced iron is produced by roasting for 30 minutes, and the composition of direct reduced iron is: TFe: 80.06%, SiO 2 : 9.08%, S: 0.18%, and the metallization rate is 92.77%, which is consistent with the Chinese SiO in Table 1 2 The requirements of the "Technical Conditions for Direct Reduced Iron for Steelmaking" recommended by the Metal Society are far apart, see Table 1;

[0022] B, A step gained direct reduced iron is carried out following treatment:

[0023] 1), after being crushed by a conventional crusher of the prior art, it is then ground to below 2mm by a grinding machine, wherei...

Embodiment 2

[0027] The equipment used is with embodiment 1;

[0028] A, rotary hearth furnace direct reduced iron are with the A step of embodiment 1;

[0029] B, A step gained direct reduced iron is carried out following treatment:

[0030] 1), after being crushed by a crusher of the prior art, it is then ground to below 2mm by a grinding machine, wherein the proportion of -200 mesh accounts for 35.00%;

[0031] 2), under the condition that the magnetic field strength is 160kA / m, carry out magnetic separation to the reduced iron that step A is crushed and finely ground with a conventional magnetic separator of the prior art, select iron powder and gangue, and dissociate the vein Stone discarded to get TFe: 92.10%, SiO 2 : 3.10%, S: 0.085%, high-quality iron powder with a metallization rate of 94.84%;

[0032] 3), the iron powder that magnetically selects is filtered with the ZPG-100 disk type vacuum filter of prior art, after dehydration, with the iron powder of the water content 9% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com