Method for preparing sintering-expanded haydite by taking red mud of Bayer process as main raw material

A main raw material, the technology of Bayer method, applied in the direction of solid waste removal, sustainable waste treatment, solid waste management, etc., can solve the problems of high difficulty and low degree of development and utilization, and achieve uniform internal pores and good vitrification degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

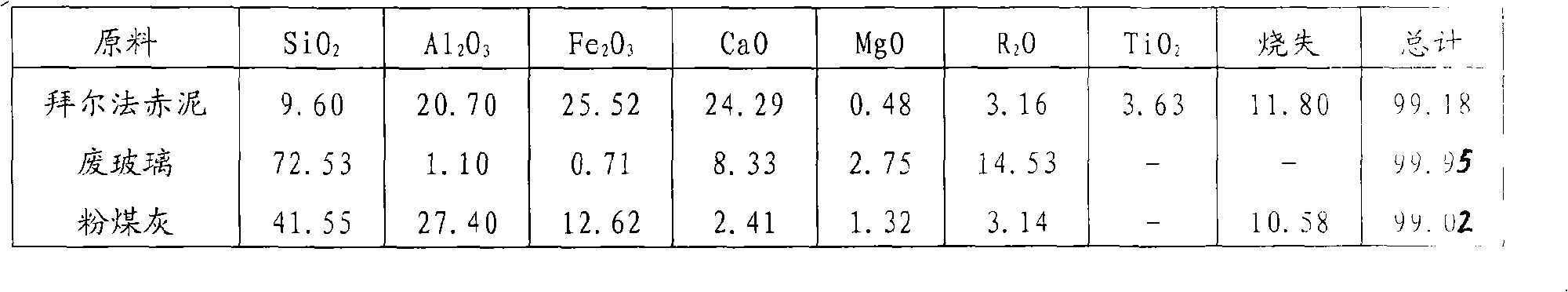

[0010] Grind Guangxi Pingguo Al Bayer process red mud, Guilin power plant fly ash, and waste glass (see Table 1 for its chemical composition) and pass through a 160-mesh sieve. Then according to the mass ratio, Bayer process red mud: fly ash: waste glass: starch: carbon powder: sodium hexametaphosphate = 50: 25: 20: 2: 2: 1, mix evenly, add 5% water of raw material quality , stirred for 5 minutes, and formed into balls after being stale for 20 minutes. After forming the balls, put the pellets into an oven and bake at 105°C for 2 hours. After drying, put them into a muffle furnace at 600°C for preheating for 10 minutes, then quickly move them to a high-temperature silicon-molybdenum furnace and bake at 1140°C for 10 minutes. The discharge ball is forced to cool.

[0011] The prepared incinerated ceramsite has a good degree of vitrification on the outer surface, relatively uniform internal pores, mainly closed pores, its water absorption rate is less than 1%, and its bulk densi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com