Improved heat-shrinking clamping method for slow-wave system of helical traveling wave tube

A technology of slow wave system and helical wire, which is applied in the manufacture of electrode systems, discharge tubes/lamps, ships or lead wires, etc. It can solve problems such as poor heat dissipation, poor structural firmness, and complicated processes, and achieve heat dissipation capabilities Improve and reduce contact thermal resistance, and precisely control the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

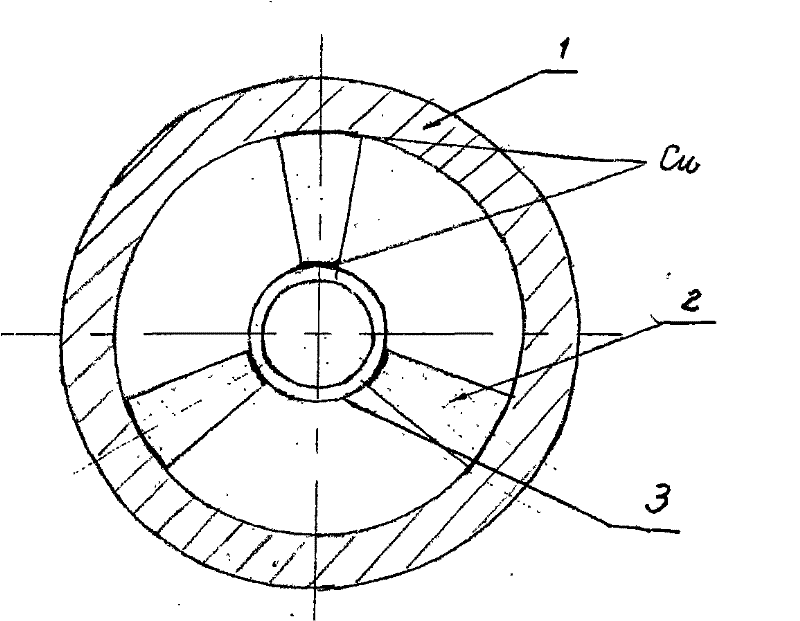

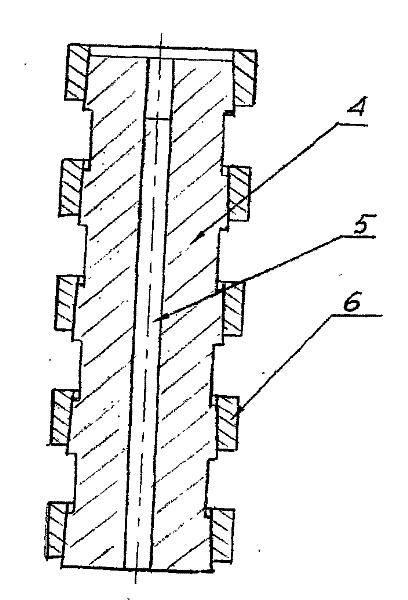

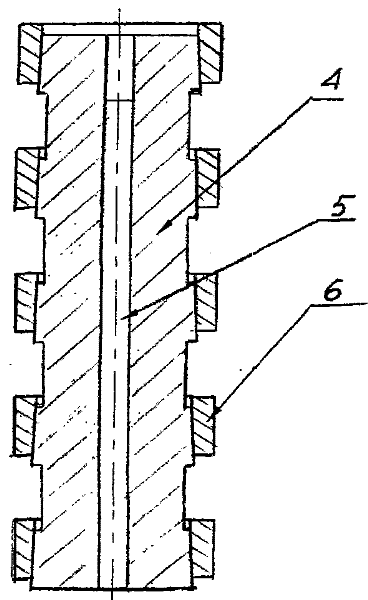

[0009] The core of the technical solution of the present invention is to use a specially designed conical fixture for thermal shrinkage clamping. At high temperature, the slow wave line assembly of the helical traveling wave tube is always under a certain pressure according to the thermal expansion coefficient of different materials. The fixture ensures that the slow wave line components are evenly stressed within the range of temperature rise and fall, and the contact between the helix, the clamping rod and the shell is transitioned with a copper layer with good thermal conductivity, and they form diffusion welding under high temperature and high pressure. A good thermal contact is obtained, the thermal resistance is reduced, and thus the heat dissipation capability of the slow wave line structure is improved.

[0010] During specific implementation, the tube shell is cold-pressed on the cold spring clamp, the helix and the medium clamping rod are fixed with the clamp, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com