High-elastic wear-resistant calendered film production process

A technology for calendering film and production process, applied in the field of high-elasticity and wear-resistant calendering film production technology, can solve the problems of increased torque, insufficient elasticity and wear resistance, etc., to increase power, increase effect and change, Satisfy the effect of high elasticity and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

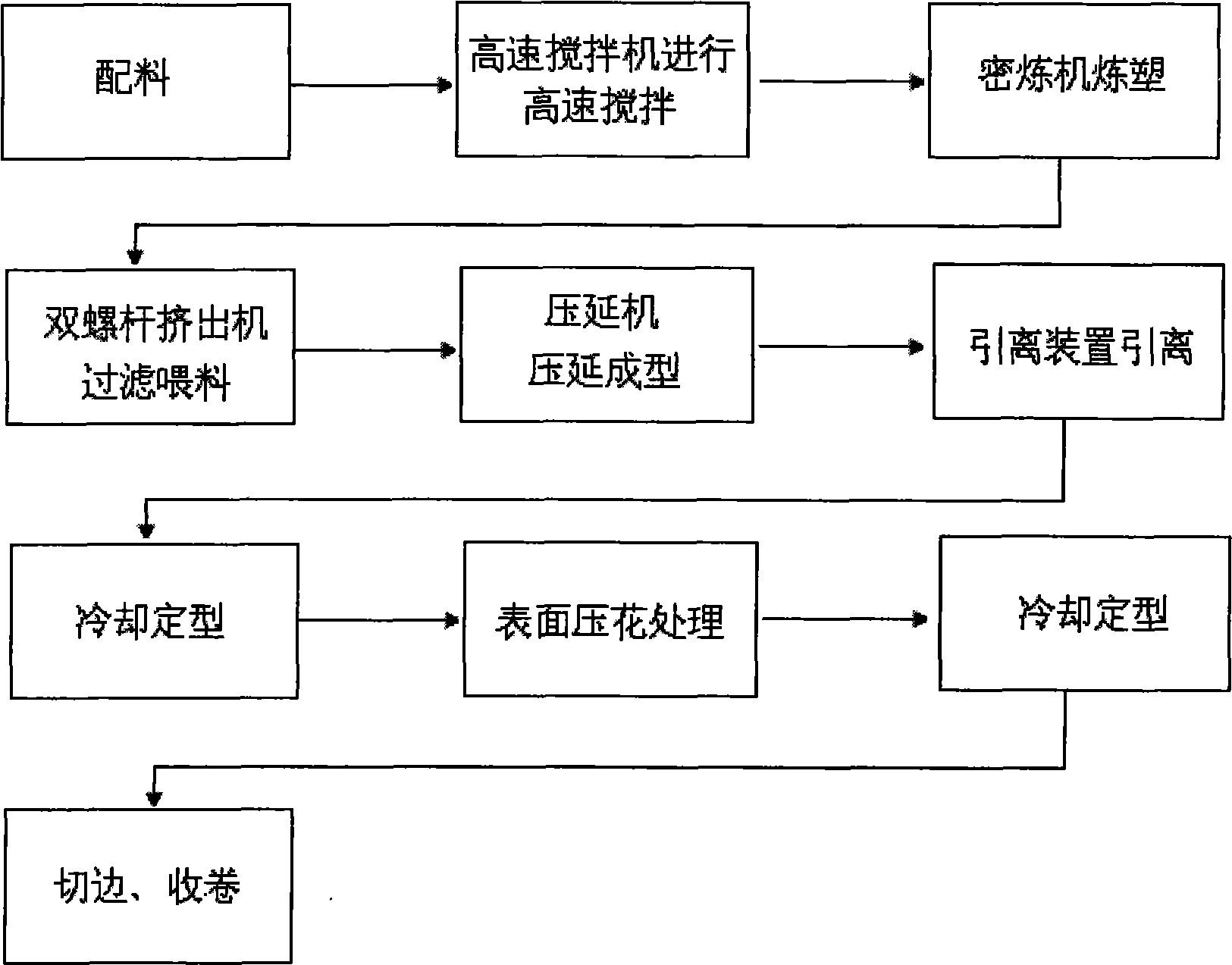

Image

Examples

Embodiment 1

[0033] The raw material formula of the high elastic and wear-resistant calendered film is according to the conventional PVC calendered film formula; or, according to the following raw material ingredients: PVC-K-60: 100PHR; DOP: 28 PHR; DOA: 6PHR; ultraviolet absorber UV-531: 0.18 PHR ; Liquid barium-zinc composite stabilizer CRV-301H: 1.8 PHR; Pigment 3PHR; Calcium carbonate CaCO 3 : 5phr.

[0034] Wherein, that is to say, the K value of the PVC used is 60-65.

[0035](1) Batching: The various ingredients of the high-elastic wear-resistant calendered film are weighed according to a certain ratio, the so-called production formula, and the metering of the liquid is carried out; the batching step can be automatically obtained from the storage tank according to the required formula. measurement;

[0036] (2) High-speed stirring: Put the mixed materials into a high-speed mixer for stirring. The low-speed stirring time is 20 seconds, the high-speed stirring time is 200 seconds, t...

Embodiment 2

[0045] The raw material formula of the high elastic and wear-resistant calendered film is according to the conventional PVC calendered film formula; or, according to the following raw material ingredients: PVC-K-65: 100 PHR; DOP: 42 PHR; DOA: 12 PHR; UV absorber UV-531: 0.25 PHR; liquid barium zinc composite stabilizer CRV-301H: 1.8 PHR; pigment 10PHR; calcium carbonate CaCO 3 : 10 PHR.

[0046] The K value of the PVC used is 60-65.

[0047] The specific process steps are

[0048] (1) Batching: The various ingredients of the high-elastic wear-resistant calendered film are weighed according to a certain ratio, the so-called production formula, and the metering of the liquid is carried out; the batching step can be automatically obtained from the storage tank according to the required formula. measurement;

[0049] (2) High-speed stirring: Put the mixed materials into a high-speed mixer for stirring. The low-speed stirring time is 20 seconds, the high-speed stirring time is 2...

Embodiment 3

[0058] The raw material formula of the high elastic and wear-resistant calendered film is according to the conventional PVC calendered film formula; or, according to the following raw material ingredients: PVC-K-63: 100PHR; DOP: 35PHR; DOA: 10 PHR; UV absorber UV-531: 0.20 PHR ;Liquid Barium Zinc Composite Stabilizer CRV-301H: 1.8 PHR; Pigment 7 PHR; Calcium Carbonate CaCO 3 : 8 PHR.

[0059] The K value of the PVC used is 63.

[0060] The specific process steps are

[0061] (1) Batching: The various ingredients of the high-elastic wear-resistant calendered film are weighed according to a certain ratio, the so-called production formula, and the metering of the liquid is carried out; the batching step can be automatically obtained from the storage tank according to the required formula. measurement;

[0062] (2) High-speed stirring: Put the mixed materials into a high-speed mixer for stirring. The low-speed stirring time is 20 seconds, the high-speed stirring time is 230 sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com