Composite modification sealing friction pair of laser texturing and alloyage and processing method thereof

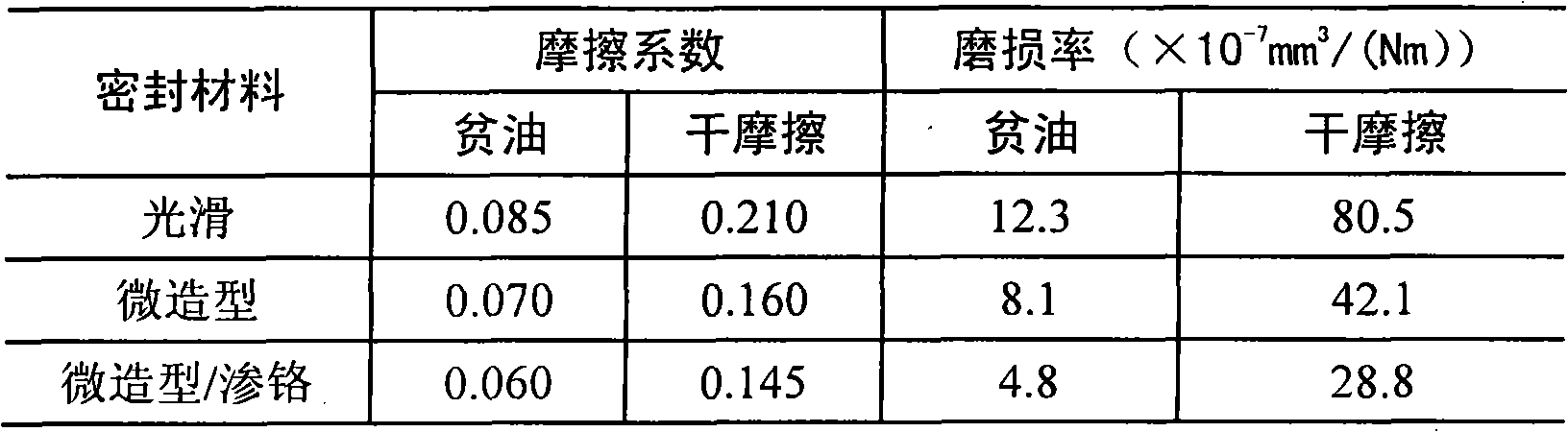

A technology of sealing friction and compound modification, which is applied in the direction of engine sealing, metal processing equipment, manufacturing tools, etc., can solve the problems of not considering the impact of the wear resistance of the sealing ring, high friction coefficient of the sealing friction pair, wear, etc., to achieve Improve friction and wear properties, improve surface wear resistance, and reduce wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: 45 steel sealing rings (outer diameter 44mm, inner diameter 36mm, thickness 8mm, hardness HRC25, its chemical composition (wt%) are C: 0.46; Mn: 0.67; Si: 0.28; P: 0.017; S: 0.025 ; Cr: 0.04) polished to Ra = 0.02 ~ 0.04 μm, ultrasonically cleaned with acetone for 3 minutes;

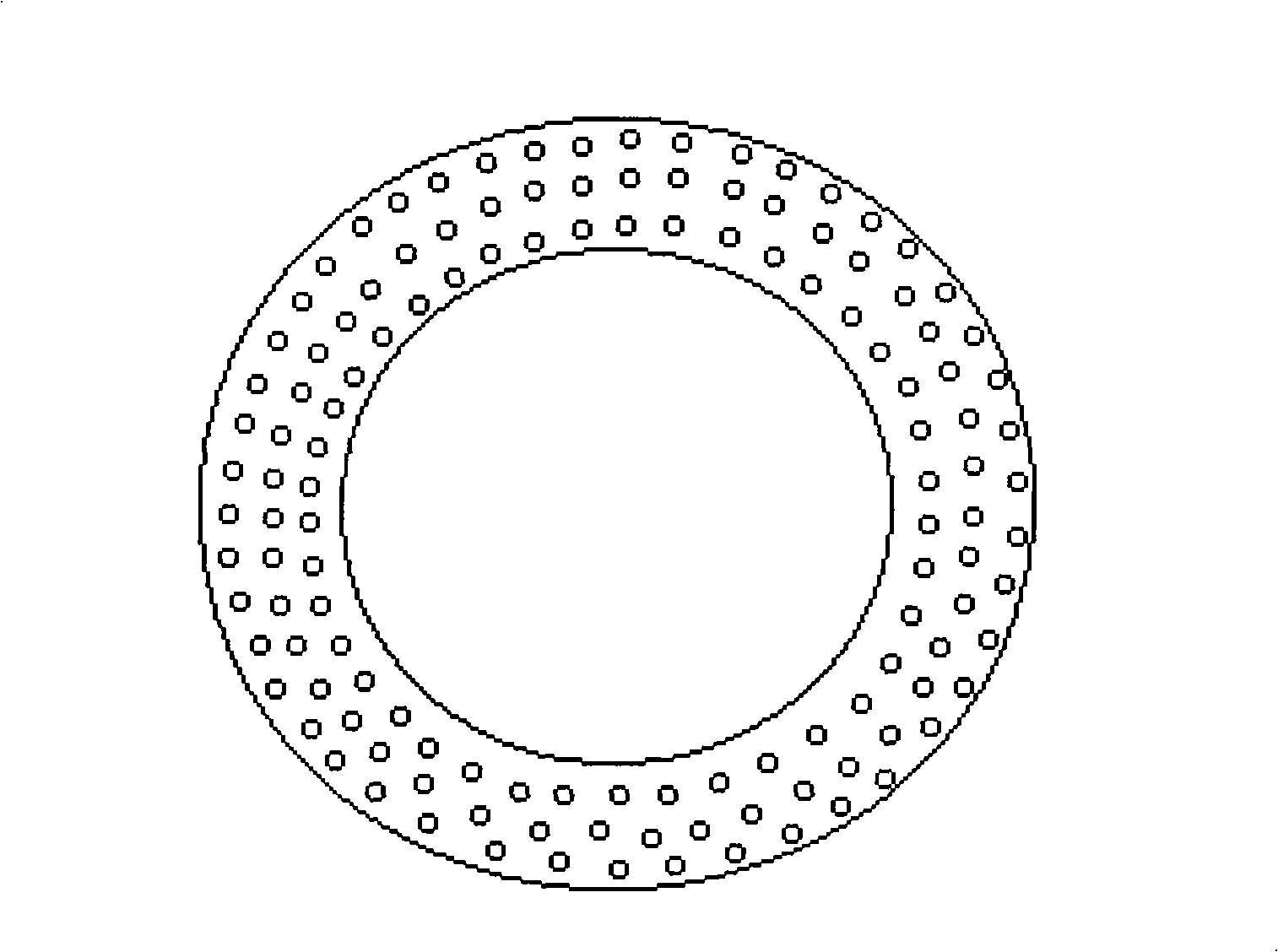

[0021] Use a Nd:YAG pulse laser with a wavelength of 1064nm, an output pulse energy of 30μJ, a pulse frequency of 1-100Hz, and a pulse width of 450-500ns to process the surface of the sealing material such as figure 1 Shown are micropores with a diameter of 200 μm, a depth of 20–30 μm, a circumferential distance of 300 μm, an axial distance of 300 μm, and a density of 20.9%.

[0022] Put the etched micromodeling sample into a 15KW double-glow plasma metallization furnace, and use it as the cathode, with pure chromium (φ100mm×5mm, purity 99.9%) as the source, the distance between the cathode and the source is 20mm, and the furnace is evacuated to 1.0×10 -2 Pa, fill 99.9% high-purity...

Embodiment 2

[0027] Embodiment 2: 45 steel seal rings (outer diameter 44mm, inner diameter 36mm, thickness 8mm, hardness HRC25, its chemical composition (wt%) is C: 0.46; Mn: 0.67; Si: 0.28; P: 0.017; S: 0.025 ; Cr: 0.04) polished to Ra = 0.02 ~ 0.04 μm, ultrasonically cleaned with acetone for 3 minutes;

[0028] Use Nd:YAG pulsed laser (laser wavelength: 1064nm; laser output pulse energy: 30μJ; laser pulse frequency: 1-100Hz; laser pulse width: 450-500ns) to process such as figure 1 Shown are micropores with a diameter of 100 μm, a depth of 20-30 μm, a circumferential distance of 800 μm, an axial distance of 800 μm, and a density of 2%.

[0029] Put the sample that has undergone laser micromodeling into a 15KW double-glow plasma metallization furnace, and use it as the cathode, with pure molybdenum (φ100mm×5mm, purity 99.9%) as the source, the distance between the cathode and the source is 20mm, and the furnace is evacuated to 1.0×10 -2 Pa, fill 99.9% high-purity argon gas to 40-45Pa, w...

Embodiment 3

[0034] Embodiment 3: 45 steel rings (outer diameter 44mm, inner diameter 36mm, thickness 8mm, hardness HRC25, its chemical composition (wt%) are C: 0.46; Mn: 0.67; Si: 0.28; P: 0.017; S: 0.025; Cr: 0.04) polished to Ra=0.02~0.04μm, ultrasonic cleaning with acetone for 3min;

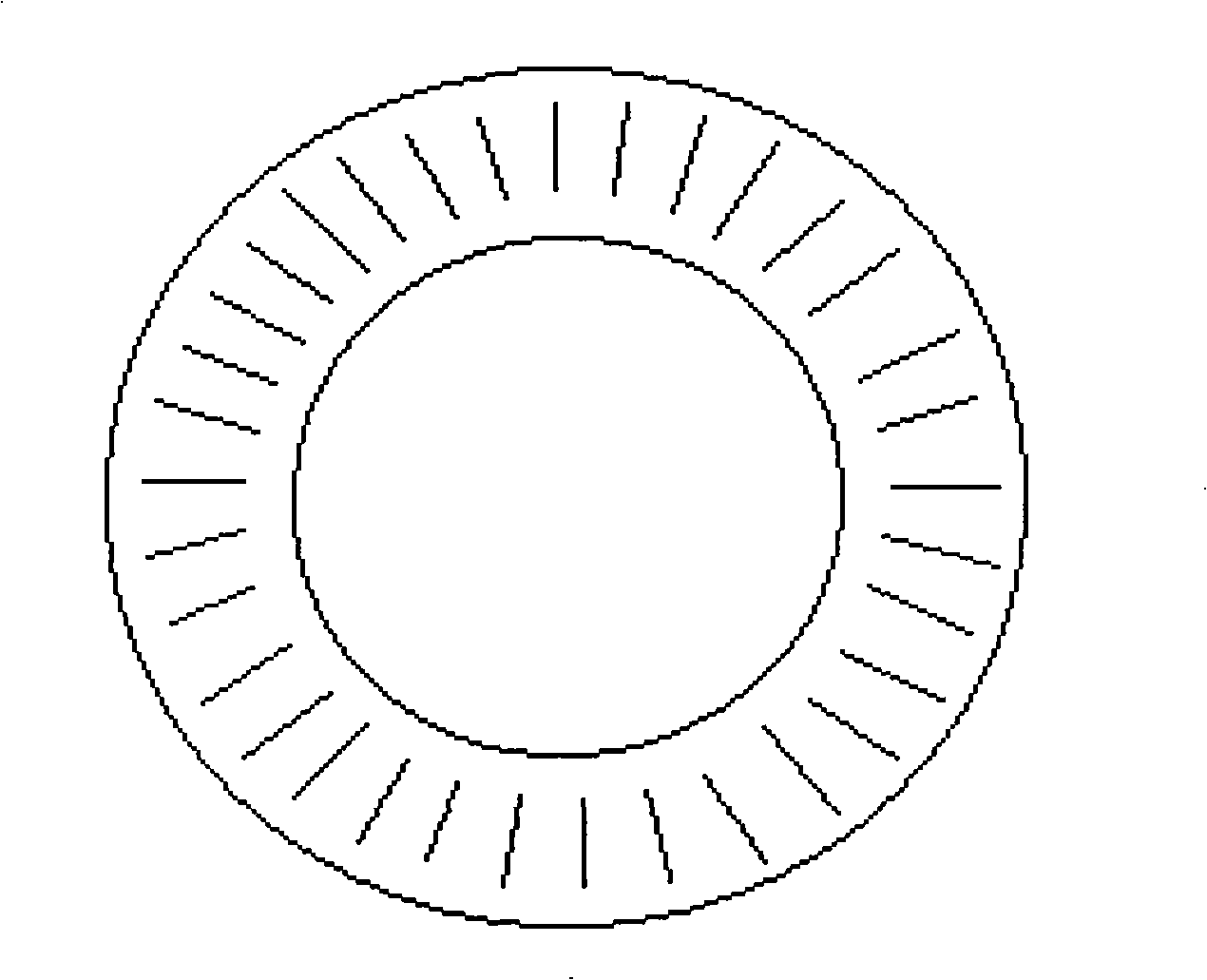

[0035] Use Nd:YAG pulsed laser (laser wavelength: 1064nm; laser output pulse energy: 30μJ; laser pulse frequency: 1-100Hz; laser pulse width: 450ns) to process the sealing material surface such as figure 2 Shown are grooves with a length of 5 mm, a width of 100 μm, a depth of 20-30 μm, perpendicular to the rubbing direction, and a pitch of 500-800 μm radially distributed at equal intervals.

[0036] Put the sample after laser micro-modelling, polishing and cleaning into a 15KW double-glow plasma metallization furnace, and use it as the cathode, with pure Mo (φ100mm×5mm, purity 99.9%) as the source, the distance between the cathode and the source is 20mm, the furnace Internal vacuum to 1.0×10 -2 Pa, fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com