Device for preparing distorted-structure polymer micron/nano composite fiber and method thereof

A nanocomposite fiber and twisted structure technology, applied in the field of material science and engineering, can solve the problems of unfavorable large-scale production, chemical agent pollution, high cost, etc., and achieve the effect of simple method, low cost and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 The device for preparing twisted fiber of single spinneret group

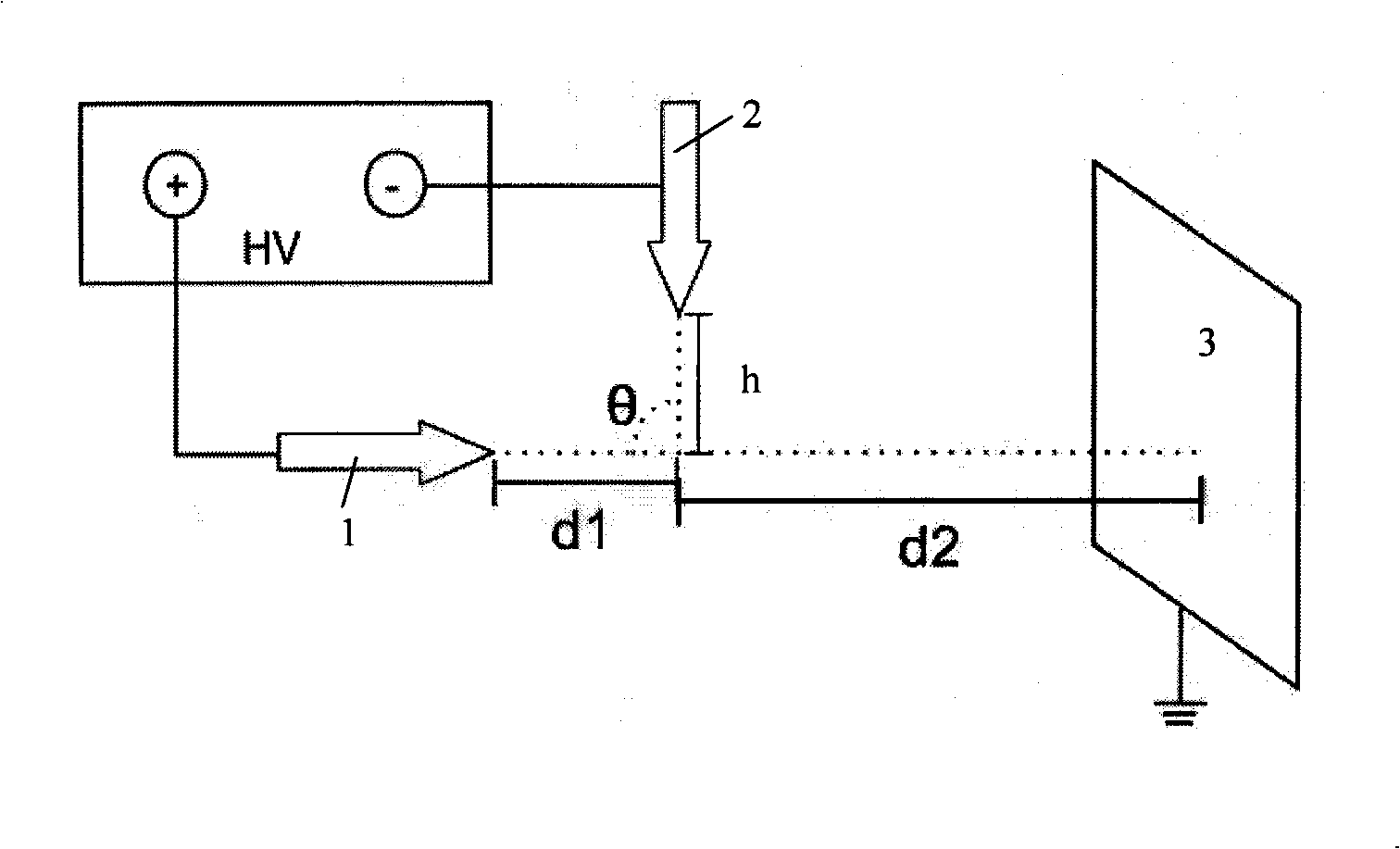

[0041] The schematic diagram of the device for preparing twisted nanofibers with a single spinneret group is shown in figure 1. The device has a spinneret group, including two spinnerets, that is, the first spinneret 1 and the second spinneret 2 . The spinneret is made of metal conductive material, one end of the metal wire is connected to the power supply, and the other end is respectively connected to the spinneret 1 and the spinneret 2 to provide the voltage required for electrospinning. Spinneret 1 is supplied with high-shrinkage polymer solution through liquid supply device, and spinneret 2 is supplied with low-shrinkage polymer solution. The voltage connected to the spinneret 1 is a positive voltage with a voltage range of 15-22KV, and the voltage connected to the spinneret 2 is a negative voltage with a voltage range of -3--8KV. d1 is the horizontal distance between the spinneret 1...

Embodiment 2

[0042] Example 2 The device for preparing twisted fibers by using multi-spinneret groups

[0043] The device for preparing twisted nanofibers of the present invention can also have multiple spinneret groups, and the positional relationship of the two spinnerets in each spinneret group is as described in Example 1. Each spinneret group is arranged in parallel, their first spinnerets 1, 1', 1"... are connected to the same electrode voltage, and the second spinnerets 2, 2', 2"... are connected to the first nozzle Electrode voltage opposite to wire head. Polymer solutions with different shrinkage ratios are added to the first spinneret and the second spinneret of each spinneret group, and the polymer solutions between the spinneret groups can be the same or different, thereby producing two sets of Twisted composite fibers of one or more components. This device greatly improves production efficiency and is suitable for large-scale production of twisted fibers of composite materia...

Embodiment 3

[0044] Example 3 Preparation of highly shrinkable polyethylene terephthalate / polytrimethylene terephthalate (HSPET / PTT) twisted fibers

[0045] Such as figure 1 The setup for making twisted composite fibers is shown. The positional relationship between the two spinnerets and the receiving device is: d1=5cm, d2=14cm, h=6cm, θ=90°.

[0046] 1) HSPET and PTT were dissolved in trifluoroacetic acid (TFA) and dichloromethane in a mixed solvent with a volume ratio of 3:2, the concentration range was 9% to 14% (mass percentage), and after stirring with a magnetic stirrer for 6 hours Start spinning. Add HSPET into spinneret 1 and PTT into spinneret 2.

[0047] 2) Provide +22KV voltage to spinneret 1.

[0048] 3) After the HSPET fiber is ejected stably, when the negative pressure is gradually provided to the spinneret 2 to -6KV, the two polymer solutions of HSPET and PTT can be stably compounded and move towards the receiving plate 3 together.

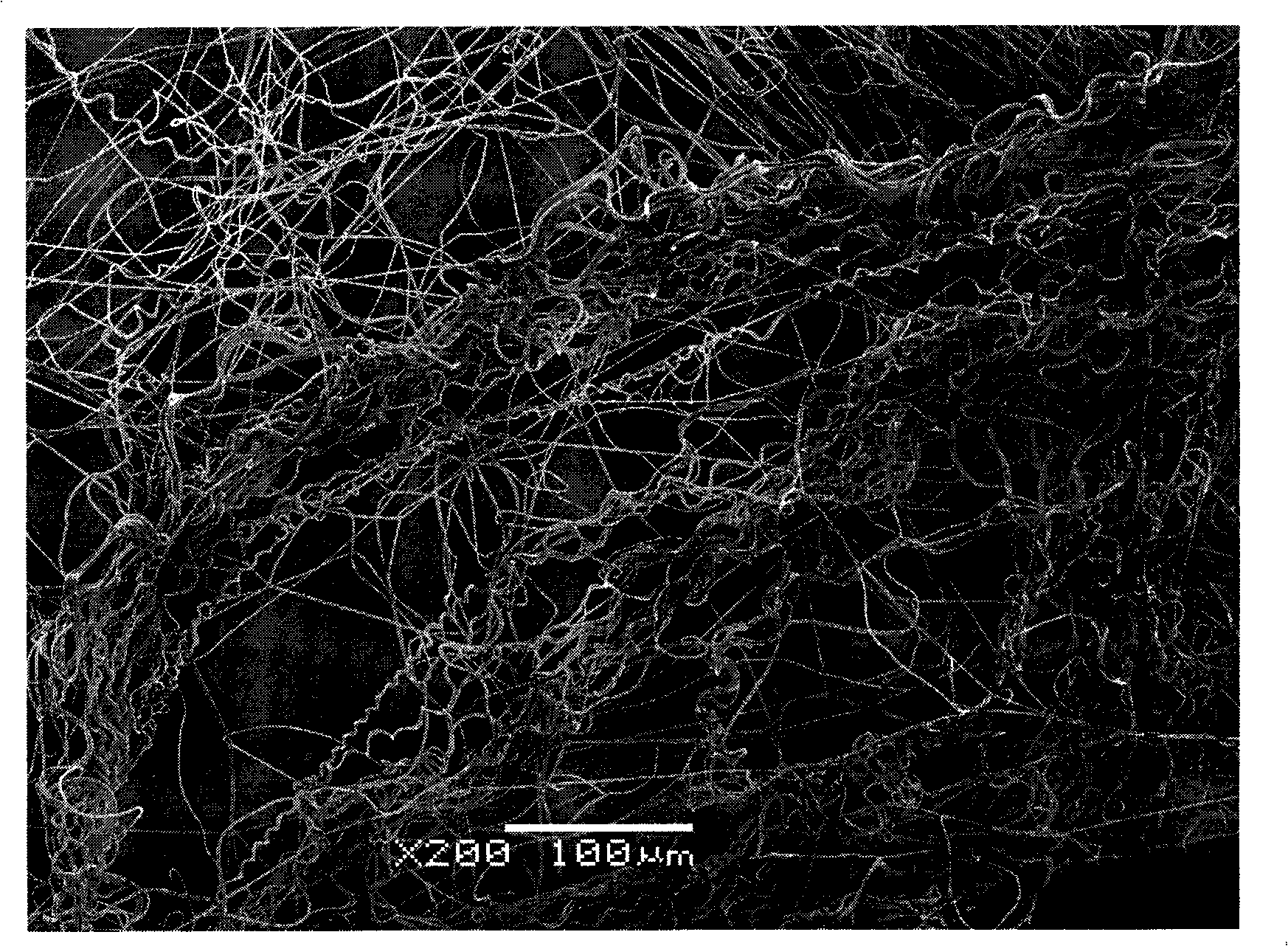

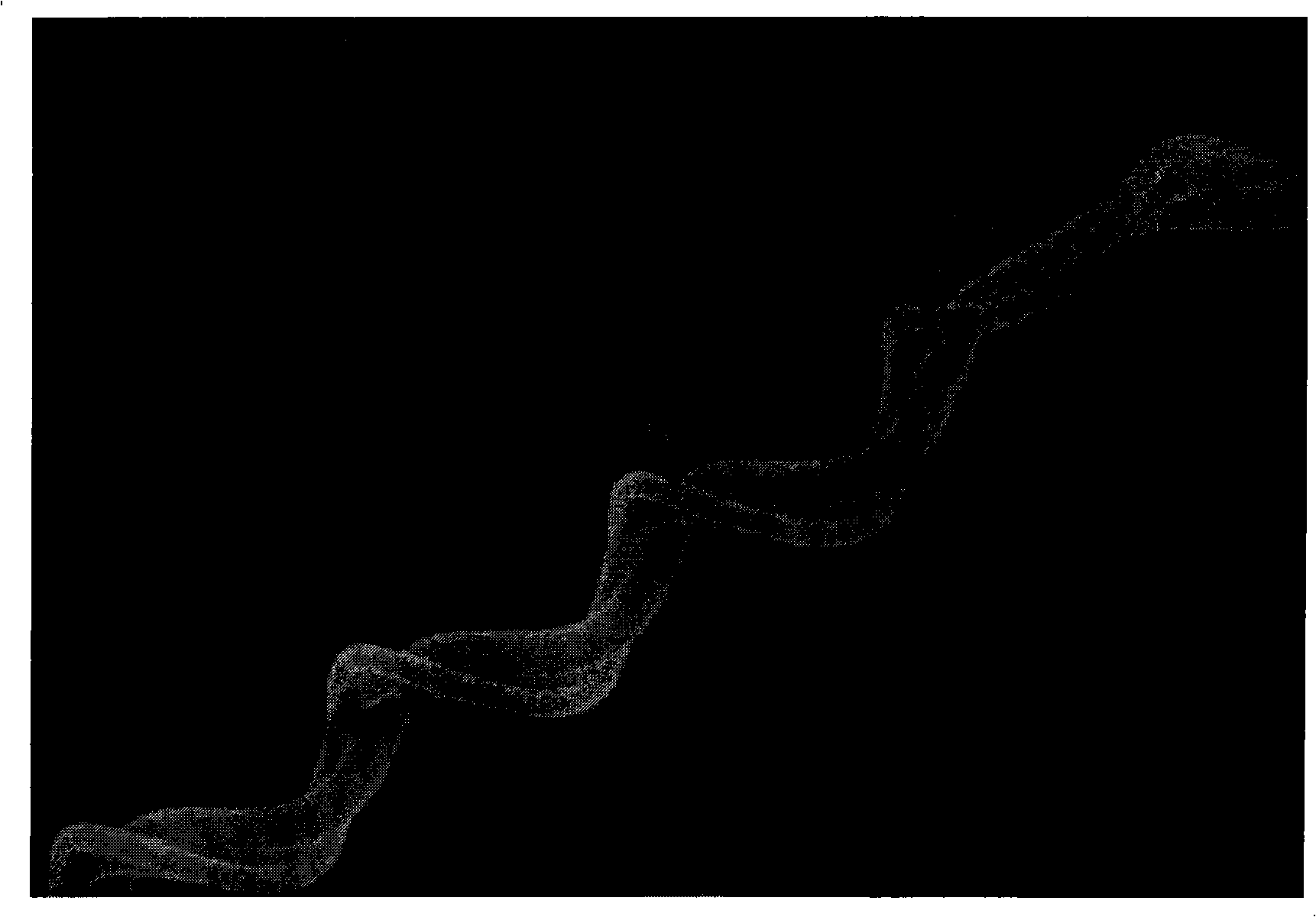

[0049] 4) The polymer solution forms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com