Curable cross-linked type ink composition and dielectric film

A technology of dielectric films and compositions, applied in inks, parts containing printed electrical components, fixed capacitors, etc., can solve the problem of poor heat resistance and chemical resistance of dielectric materials, making ultra-thin capacitors, To solve problems such as limited properties, to achieve the effects of good ink storage, good heat and chemical resistance, and good inkjet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063]

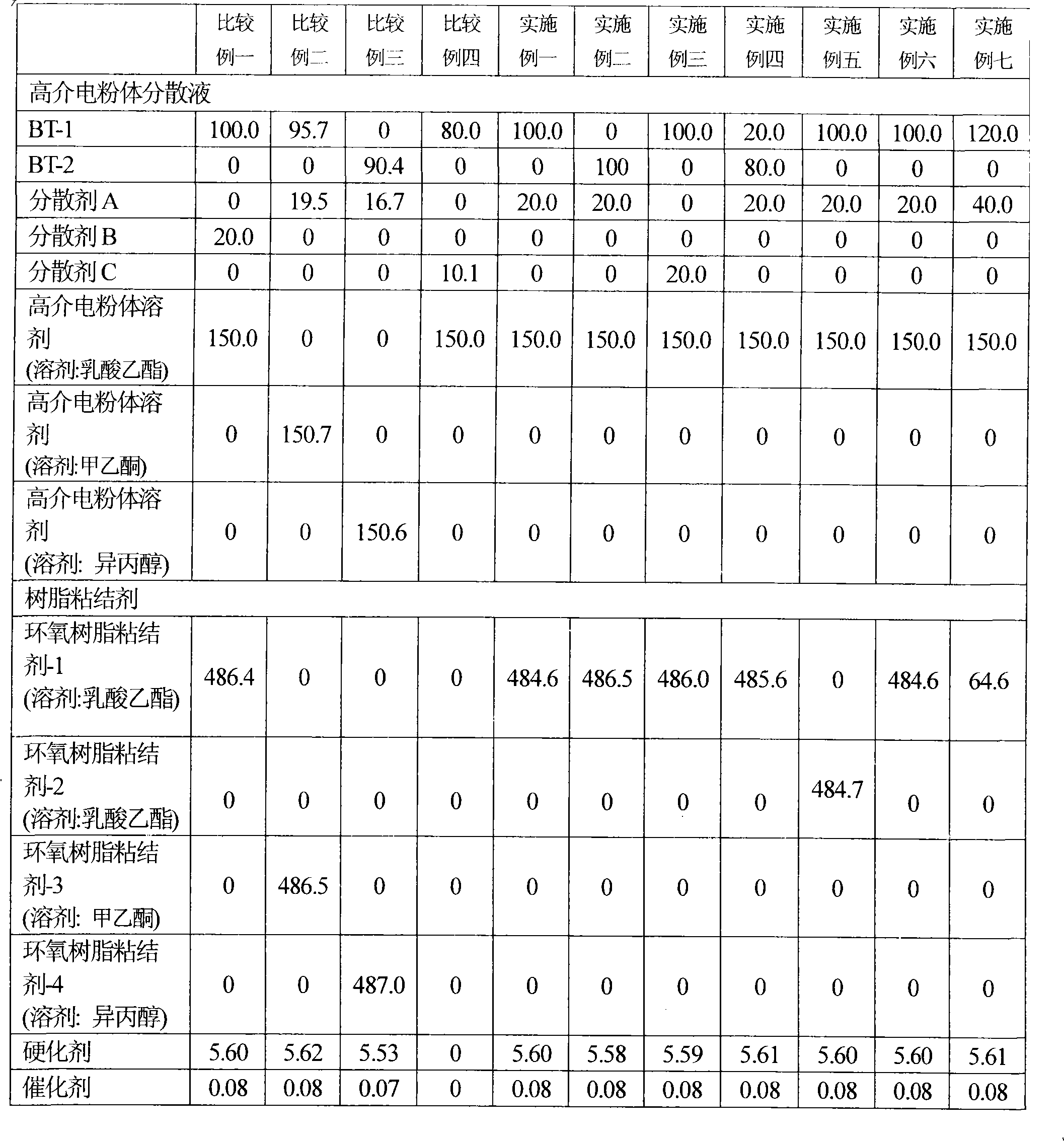

[0064] 100 grams of BaTiO with an average particle size of about 100 nm 3 (Inframat Advanced Materials, BT-1), add 20 grams of high molecular weight dispersant BYK-9010 (supplied by BYK chemie, containing acid group copolymer dispersant A), and add 760 grams of grinding medium zirconium beads and 150 gram of ethyl lactate solvent, followed by wet grinding with a sand mill for 2 hours for dispersion treatment, and then filtering and separating the grinding beads to obtain a high dielectric powder dispersion.

[0065]

[0066] 10.50 grams of bisphenol-A diglcidyl ether (bisphenol-A diglcidyl ether) (188EL, Changchun resin company, Taiwan), 7.70 grams of tetrabromo bisphenol-A epoxy resin (tetrabromo disphenol-A diglcidylether) (BEB-350 , Changchun Company, Taiwan), 2.70 grams of cyclo aliphatic epoxy resin (cyclo aliphaticepoxy) (HP-7200, DIC, Japan), 3.70 grams of multifunctional epoxy resin (Multifunctional epoxy) (EPPON502H, Nippon Kayaku) system and 460 grams o...

Embodiment 2

[0070] The preparation procedure is the same as in Example 1, but the high dielectric powder is replaced by BaTiO with an average particle size of about 300nm 3 (Prosperity Dielectrics Co., BT-2), the addition amount of each component is shown in Table 1.

Embodiment 3

[0072] The preparation procedure is the same as in Example 1, but the dispersant is changed to another lipophilic polymer dispersant KD-1 (Uniqema, Hypermer dispersant C), and the addition amount of each component is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com