Ink-jet head fixed digital jet printer with guide tape to feed medium

An inkjet head and printing machine technology, applied in printing, printing device, transportation and packaging, etc., can solve the problems of inconvenient design, installation, debugging and maintenance, difficult to mass-produce textile fabrics, and unsuitable for continuous printing, etc. Good inkjet effect, wide application range, and the effect of improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

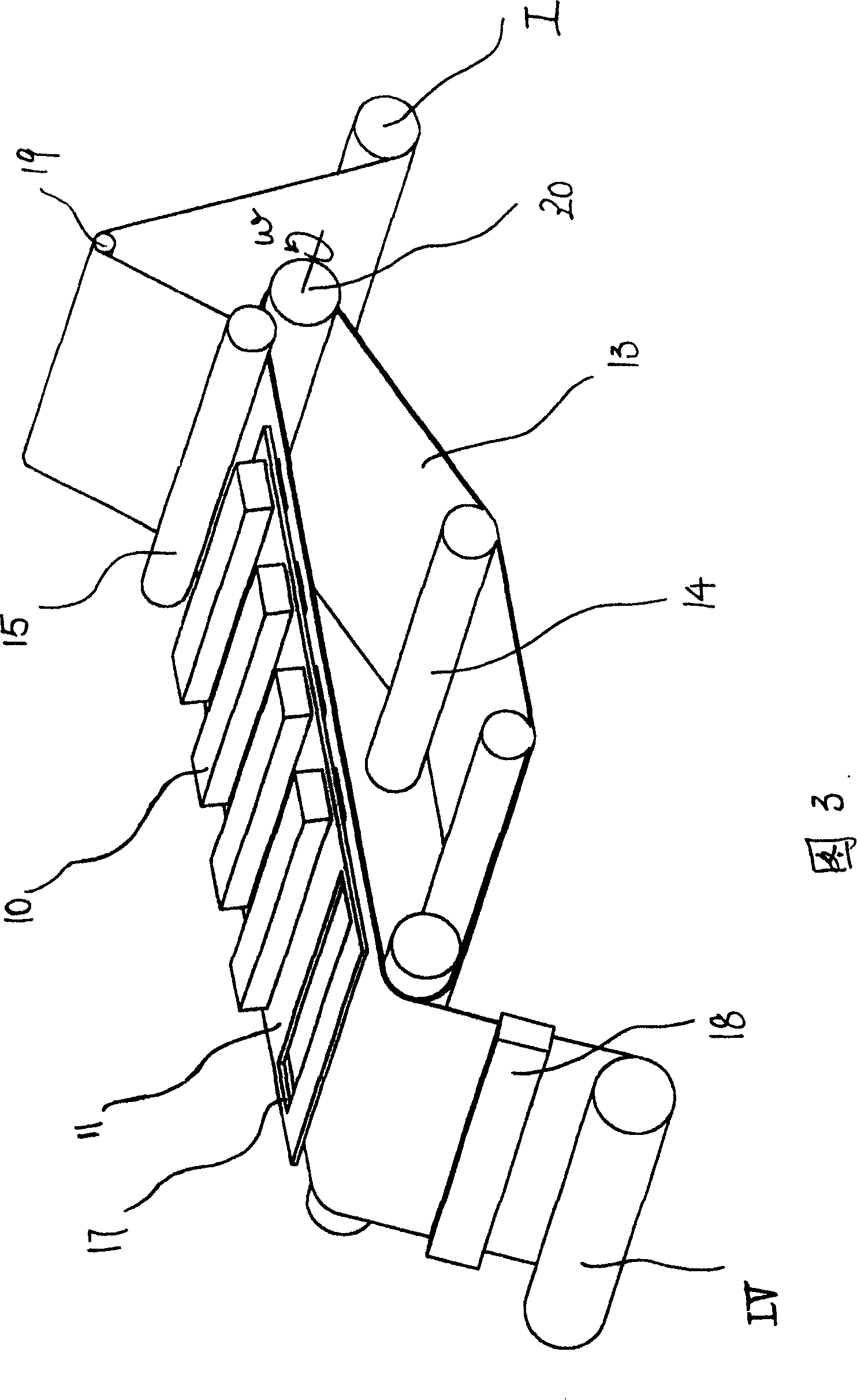

[0025]Embodiment 1: As shown in accompanying drawing 3, the guide belt mechanism of the present invention is to utilize guide belt 13 to convey printing medium 1, and guide belt 13 is supported, stretched and driven by four tension rollers 14 inside it, and drive roller The axes of 20 are parallel to each other; the two ends of the drive roller 20 each have an adjustment knob for adjusting the tension of the guide belt 13 and the parallelism between the drive rollers to ensure that the left and right tension of the guide belt is even. The perimeter of the guide belt 13 is selected according to the actual needs of the printer, and the width of the guide belt 13 needs to be slightly larger than the maximum nominal printing width of the printer. The inkjet head 10 is fixed on the nozzle installation frame 11 of the printer, it is fixed all the time, and it selects different specifications according to the width of the printer format, so that the central line of the nozzle holes 12...

Embodiment 2

[0032] Embodiment 2: What this embodiment differs from Embodiment 1 is that its ink-jet head is an ink-jet head group 16' equivalent to the ink-jet head in Embodiment 1. The equivalent inkjet head group 16' is composed of two or more small inkjet heads, and the equivalent inkjet head group 16' is arranged in at least two rows in the medium transport direction, and each row contains at least one Or more than one small inkjet head, the small inkjet heads between two adjacent rows are arranged in a staggered manner, and the distance between the head and the tail two nozzle holes on the two rows of inkjet heads (the distance perpendicular to the printing medium conveying direction) is equal to The inherent physical pitch of the nozzle holes on the small inkjet head, and make the length of the projected connection line of each nozzle hole on the combined equivalent inkjet head perpendicular to the medium conveying direction not less than the width of the printing medium, that is, ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com