Conduction band digital code spray-jet printing machine

A technology of printing machine and belt guide, applied in printing, printing device, dyeing method, etc., to achieve the effect of improving quality, smooth transmission and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

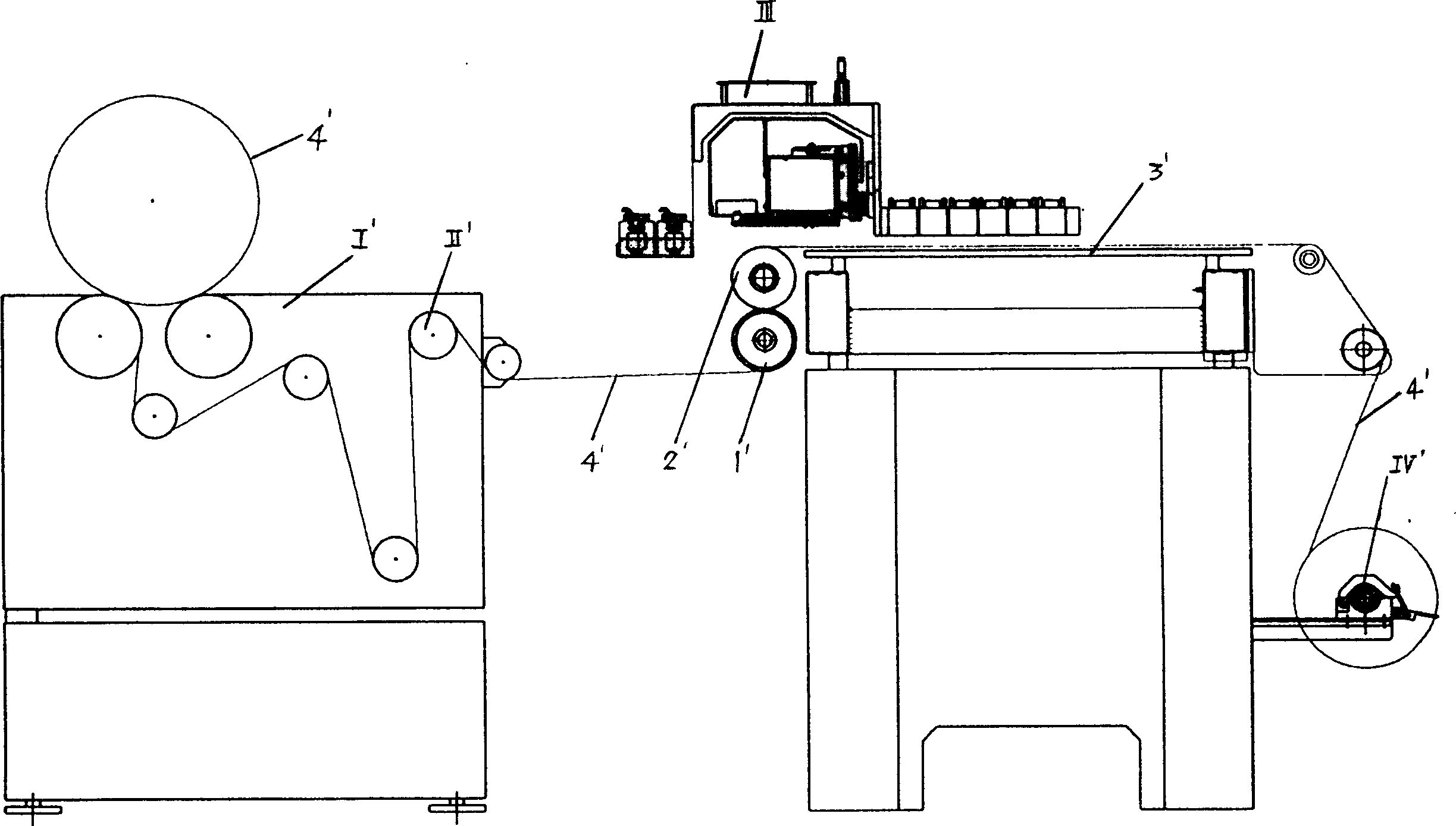

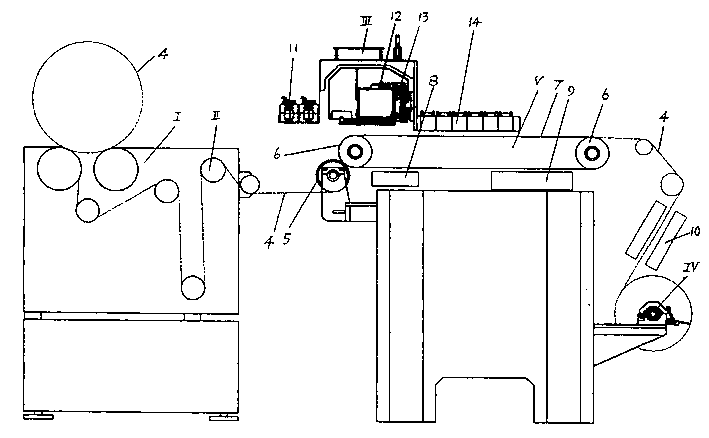

[0015] see figure 2 , the present invention is mainly made up of unwinding mechanism I, expansion mechanism II, patching mechanism 5, guide belt conveying device V, inkjet printing head III and winding device IV, wherein guide belt conveying device V includes guide belt 7 and Two drive rollers 6; inkjet printing head III includes ink supply device II, beam 12, guide rail 13, print head assembly 14 and control assembly; expanding mechanism II can be composed of double-opening spiral rollers or edge suction devices commonly used in the textile industry.

[0016] The guide belt conveying device V of the present invention uses the guide belt 7 to transmit the medium 4, the guide belt 7 is supported, tensioned and driven by two drive rollers 6 inside it, and the axes of the two drive rollers 6 are parallel to each other; the guide belt 7 The tension of the belt and the parallelism of the transmission roller 6 can be adjusted through a specific adjustment mechanism; the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com