Anion exchange resin production system and production technology

An anion resin and production process technology, applied in the direction of anion exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of increasing the production cost of anion exchange resin, high secondary treatment cost, inability to use phosphate fertilizer to produce, etc. Conducive to environmental protection, ensuring no pollution, reducing the effect of waste water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

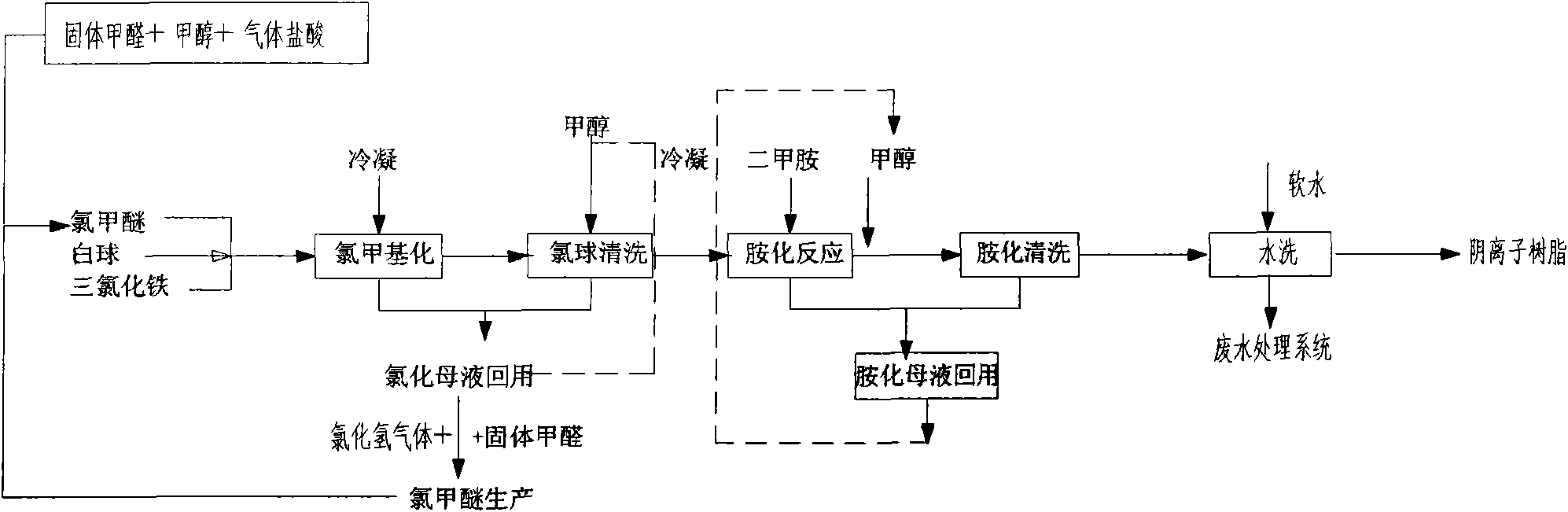

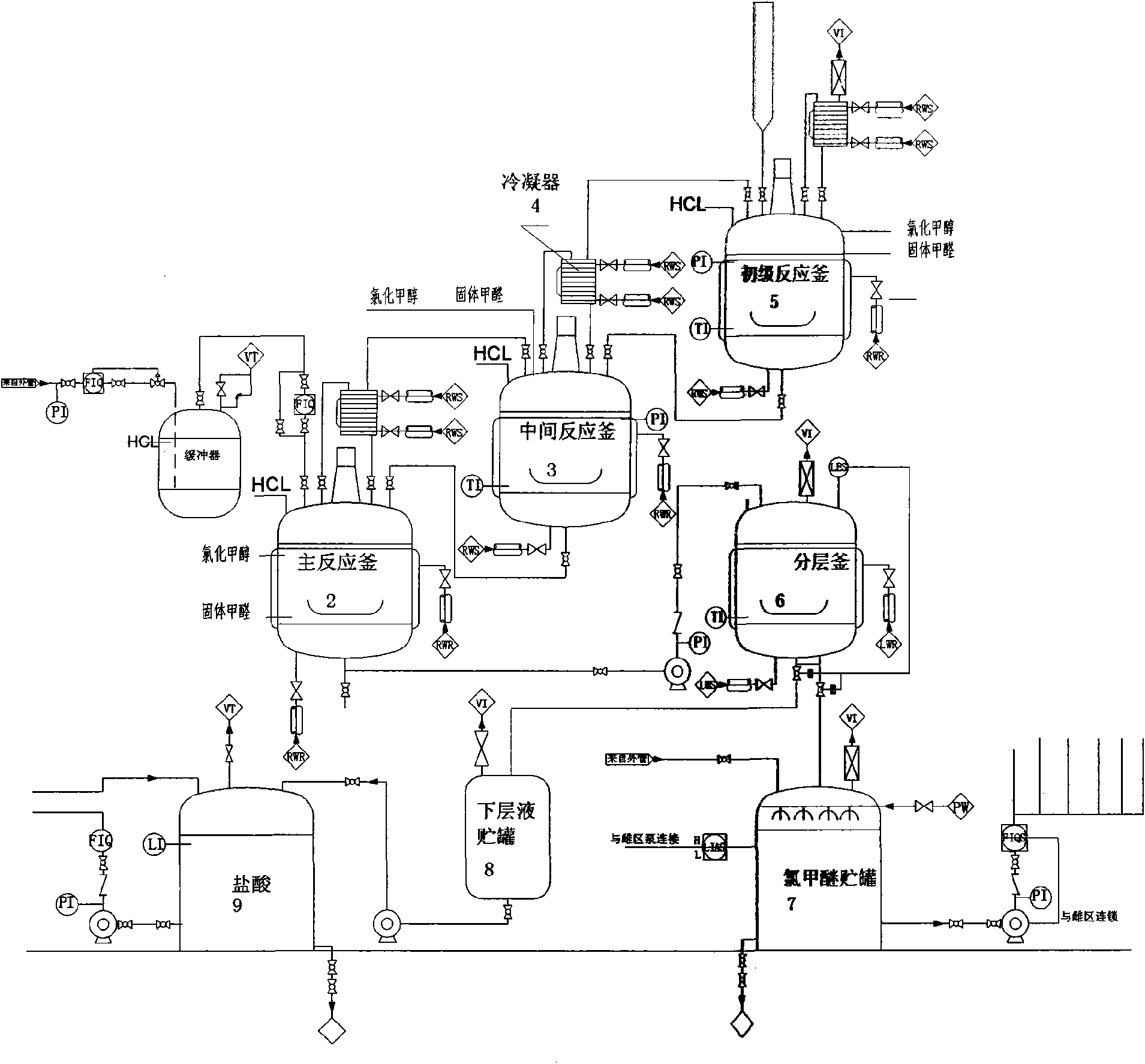

[0031] Embodiment 1: with reference to attached Figure 1~4 . The production system of anion exchange resin, it comprises chloromethyl ether production system, chloromethylation system, chlorine ball cleaning system, amination reaction system, water washing device, described chloromethylation production system outlet all the way and chlorine ball cleaning system The outlet of the chlorination mother liquor recovery system is connected with the inlet of the chloromethylation system and constitutes a chlorination mother liquor recycling and chloromethyl ether production loop.

[0032] The inlet of the buffer tank 1 in the chloromethyl ether production system is connected with hydrogen chloride gas, and the outlet is connected with the inlet of the main chlorination reactor 2 through valves and pipelines, and the outlet of the main chlorination reactor 2 passes through the valve, pipeline and intermediate reactor 3 all the way. One is connected with the outlet of the primary rea...

Embodiment 2

[0034]Embodiment 2: On the basis of embodiment 1, anion exchange resin production process, it comprises chloromethyl ether production process, chloromethylation production process, chlorine ball cleaning process, amination reaction, washing process, finally gets finished product anion resin , the chloromethyl ether required for the first production of anionic resin is produced by the chemical reaction of solid formaldehyde, methanol, and gaseous hydrochloric acid, the chlorination mother liquor produced by the chloromethylation production process and the washing liquid produced by the chlorine ball cleaning process It is sent to the recovery process of chlorination liquid, and the chlorinated methanol in the chlorination mother liquor reacts with the added solid formaldehyde and hydrogen chloride gas to obtain chloromethyl ether, which is directly used as the raw material for the production of circulating anion resin, so that chloromethyl ether is obtained by recycling.

[0035...

Embodiment 3

[0036] Embodiment 3: On the basis of embodiment 2, hydrogen chloride gas 20, chlorinated methanol 70%, solid formaldehyde 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com