Method for manufacturing patterned magnetic recording medium

A technology for magnetic recording media and manufacturing methods, applied in the direction of disc carrier manufacturing, different record carrier forms, and only a part of the coating supported by a magnetic layer, which can solve the problems of magnetic head damage, magnetic characteristic changes, and magnetic layer deterioration. , to achieve the effects of deterioration suppression, stable detection, and prevention of re-pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

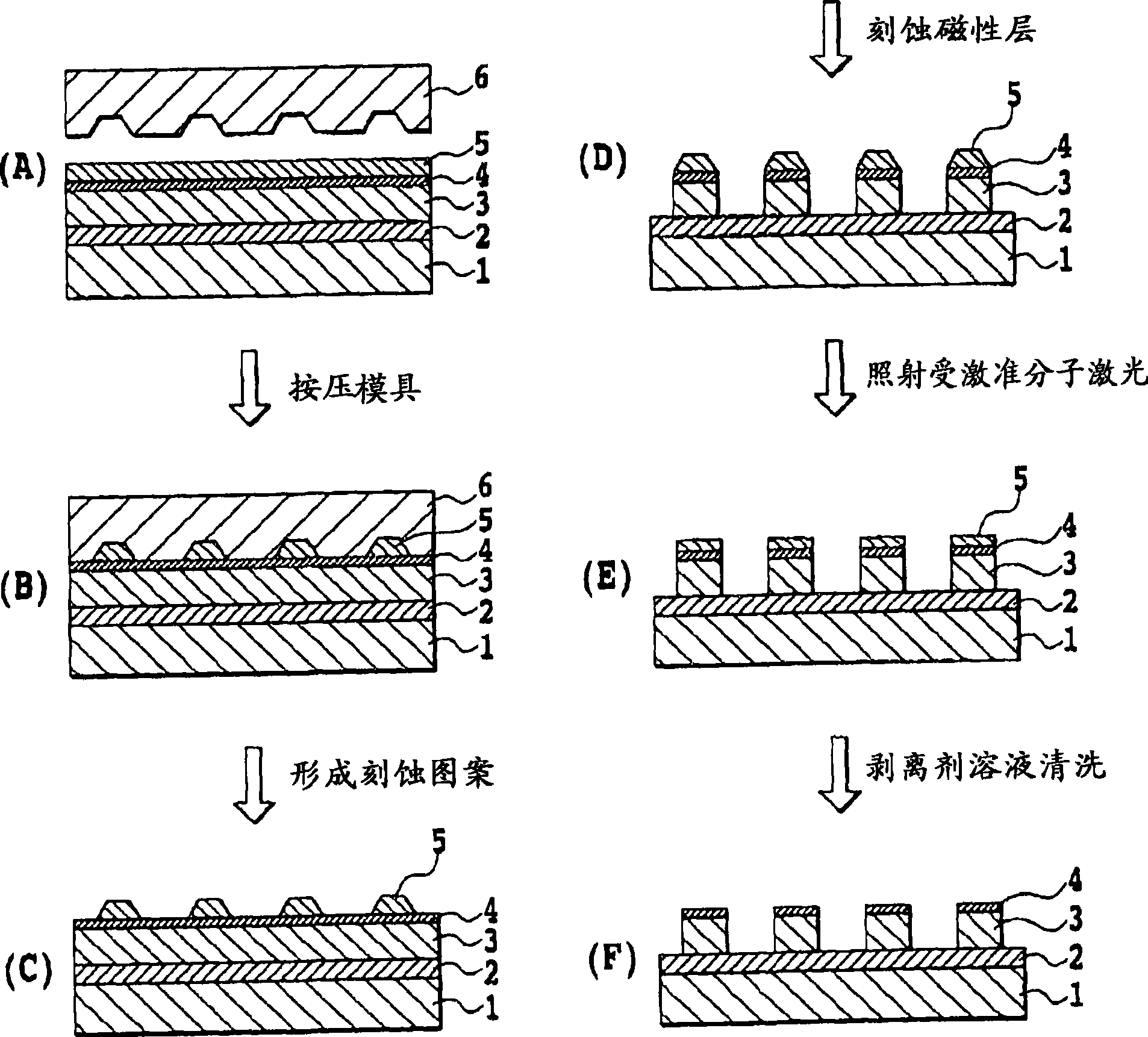

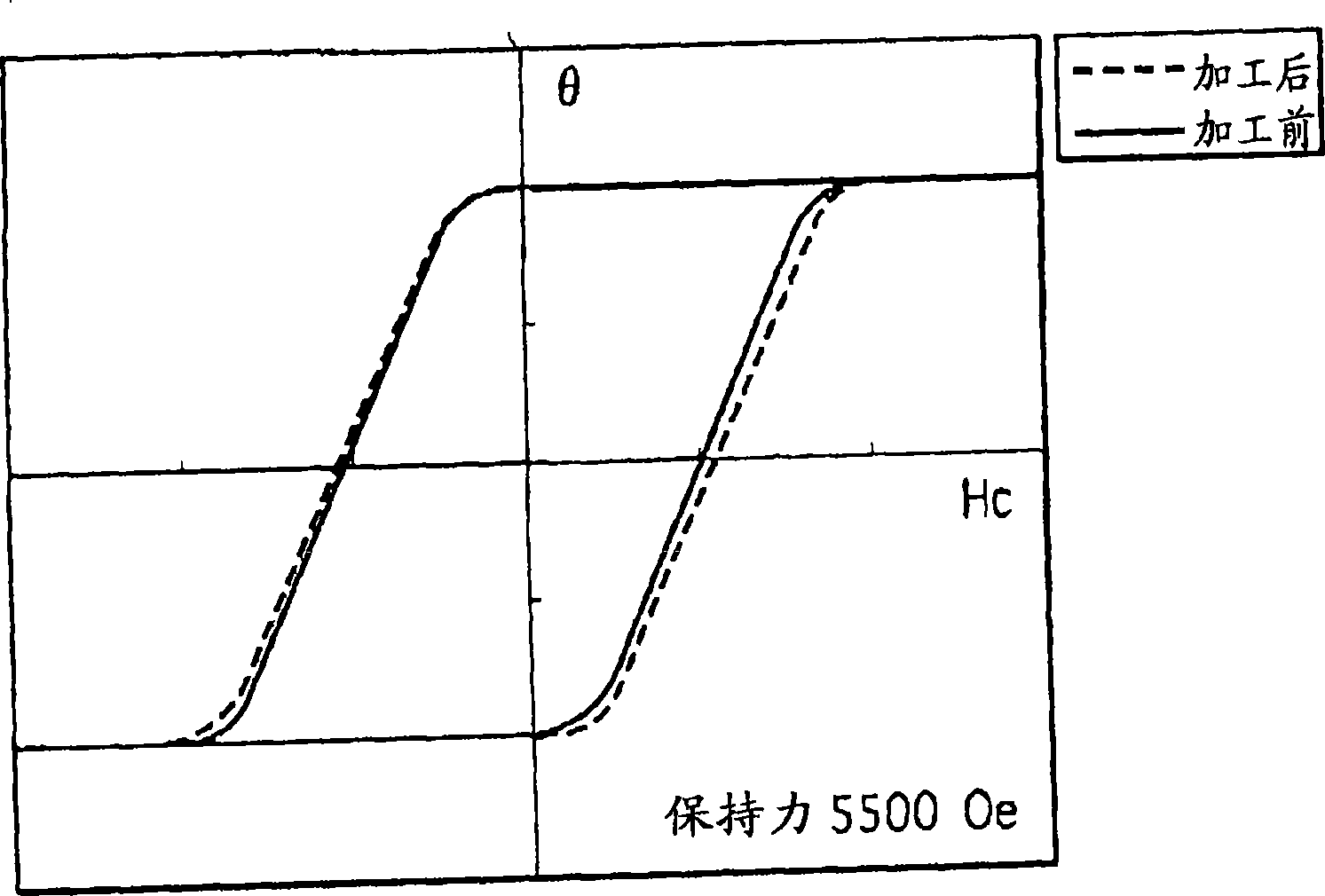

[0070] On a 2.5-inch glass substrate 1, a base layer 2 with a thickness of 30nm and a layer of CoCrPtSiO with a thickness of 20nm are laminated. 2 The magnetic layer 3 and the carbon first protective layer 4 with a thickness of 3nm were used to produce a magnetic recording medium. The recording medium has figure 2 Magnetic properties shown in solid lines. Then, a thermosetting resist mr-I-8010E (trade name, manufactured by Micro Resist Technology GmbH) with a thickness of 100 nm was applied on the first protective layer 4 by spin coating to form a resist. Etch coating 5.

[0071] A nickel mold 6 heated to 180° C., having a track-like pattern with a width of 80 nm and a depth of 60 nm, was pressed against the formed resist film 5 for 30 seconds using a pressing device at a pressure of 100 MPa (1000 bar). After 10 minutes, the resist is cured to form an etching pattern on the resist film 5 .

[0072] using O 2 After the resist film 5 remaining at the bottom of the etched pa...

Embodiment 2

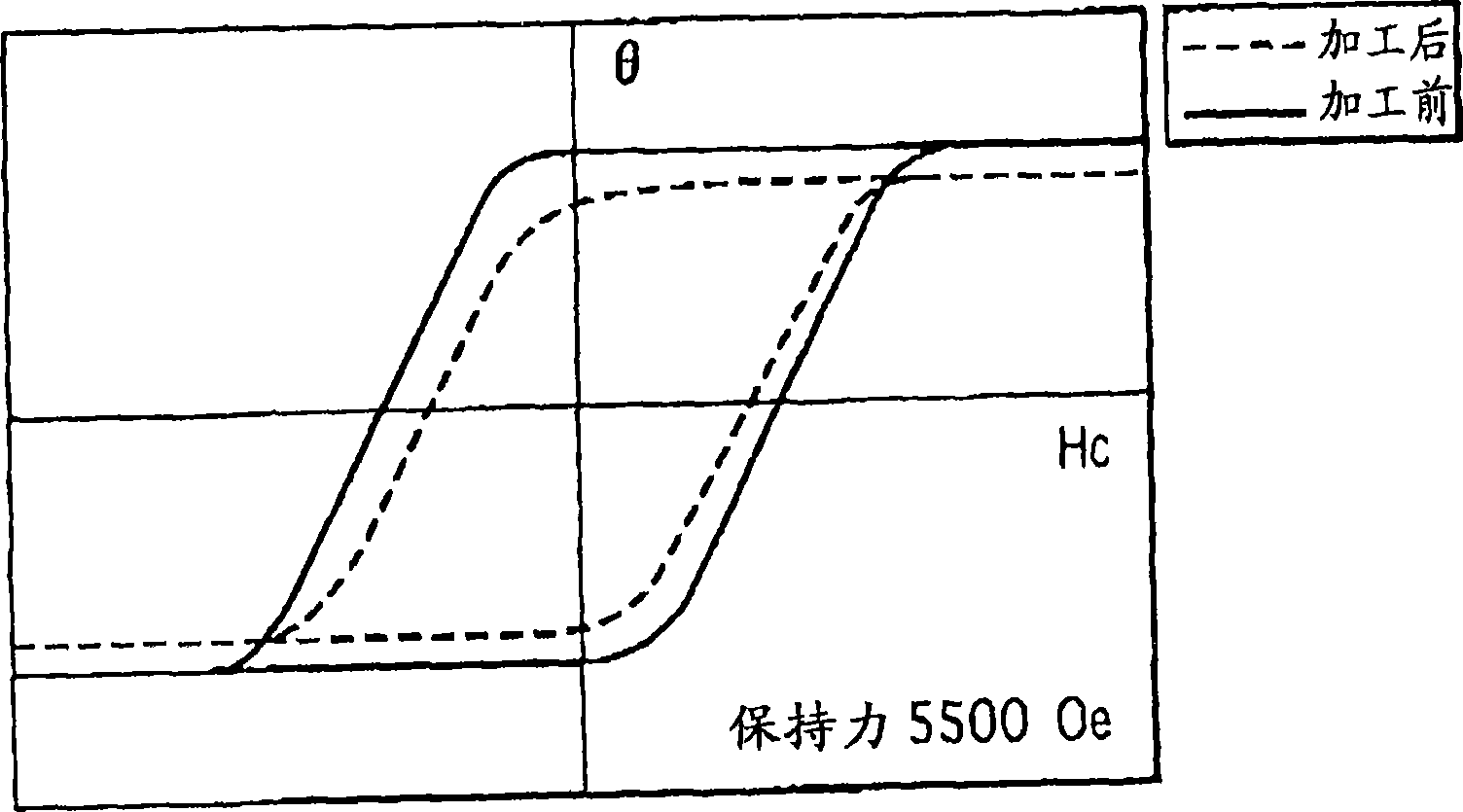

[0078] In addition to changing the irradiation atmosphere of the excimer VUV laser in Example 1 to a nitrogen atmosphere with a pressure of 0.6KPa (60mbar), and changing the irradiation distance to 2.7mm, the same conditions as in Example 1 were used to carry out anti-corrosion. The etchant film 5 is peeled off to manufacture a patterned magnetic recording medium.

[0079] By FT-IR analysis after the DMF solution cleaning treatment, it was confirmed that the resist on the first protective layer 4 was completely removed. In addition, as in Example 1, the magnetic properties of the magnetic recording medium measured by Kerr remained unchanged before and after patterning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com