Preparation method and product of lincomycin-gentamicin compound injection

A technology of gentamicin and lincomycin, which is applied in the preparation of lincomycin-gentamycin compound injection and the field of injection preparation, can solve the problems of poor thermal stability, prone to hydrolysis or oxidation reaction, Substance failure and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

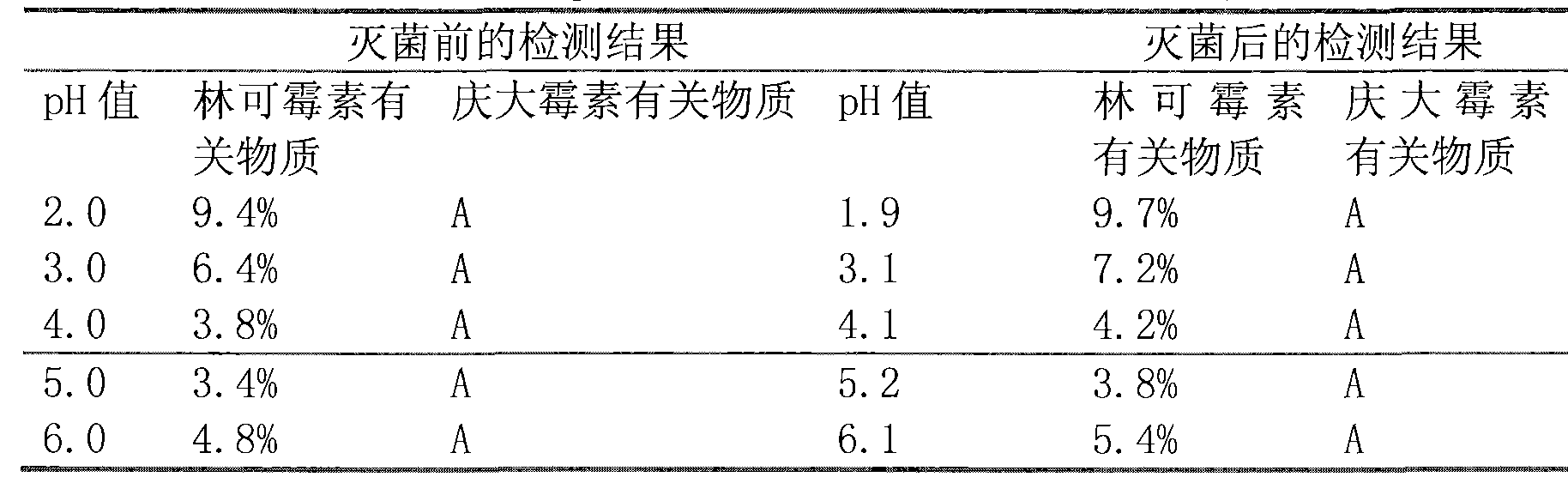

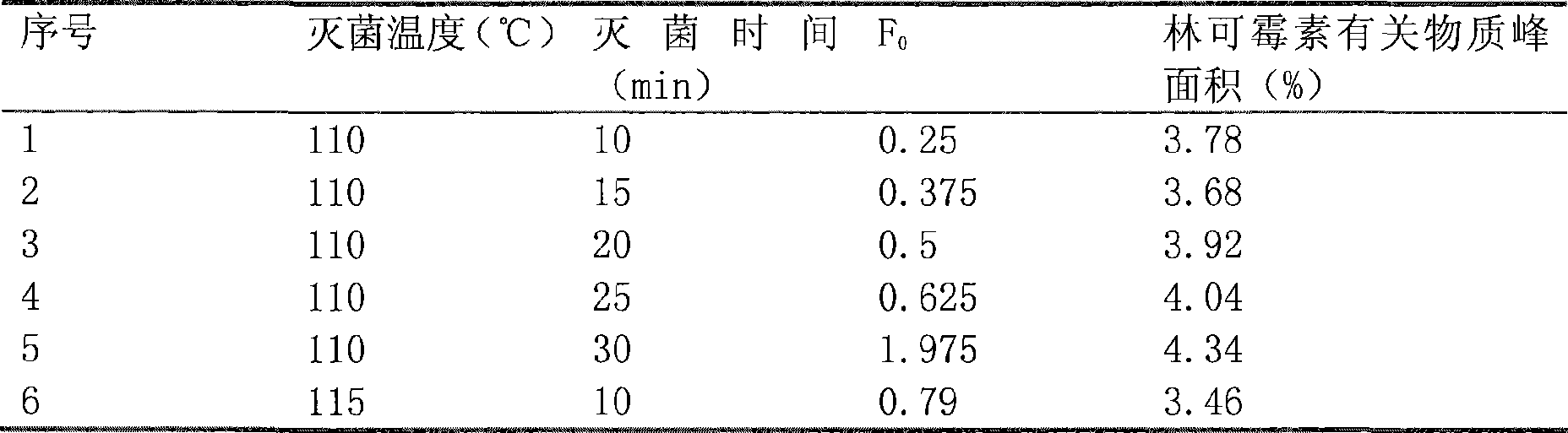

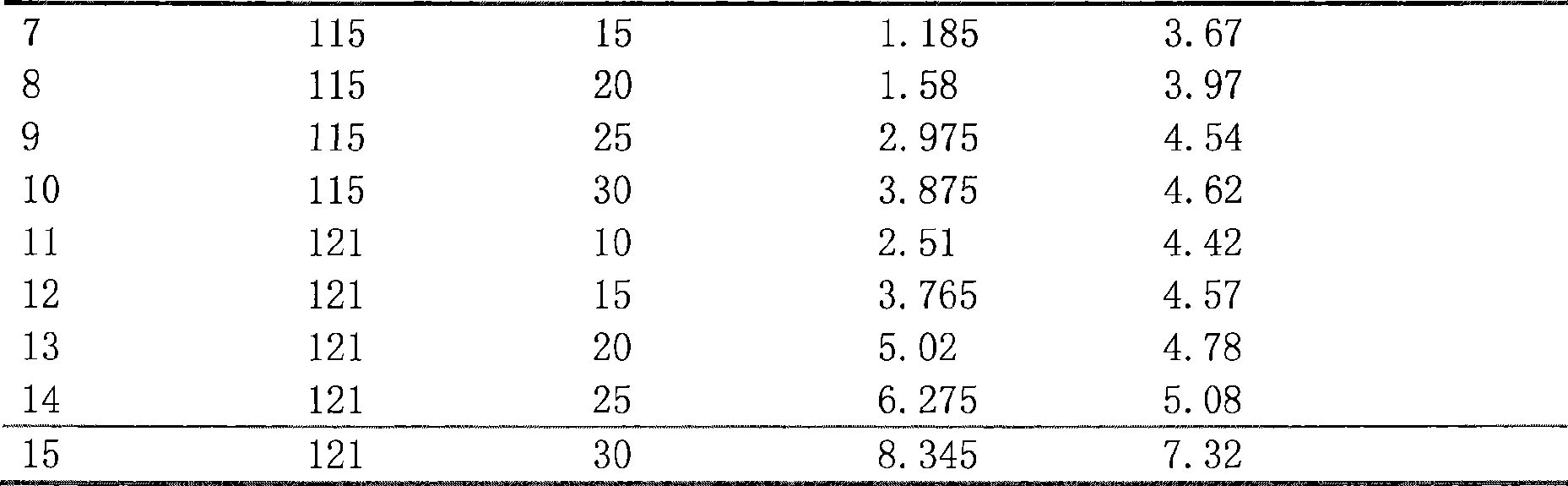

Method used

Image

Examples

Embodiment 1

[0054] Example 1 Preparation of Lincomycin-Gentamycin Compound Injection

[0055] Take 0.02% EDTA, add it to water for injection at 30°C, stir, and dissolve; respectively take gentamicin and lincomycin and add it into an appropriate amount of water for injection (30°C) and stir. Take 0.2% anhydrous sodium bisulfite and add it into the liquid medicine, and stir. Adjust the pH of the solution to 5.0 with hydrochloric acid solution, and fix the solution with water for injection. Add 0.1% needle-use activated carbon (25° C.) and stir for 20 minutes. Filter through 0.45um and 0.22um microporous membranes until clear. Fill it with nitrogen gas, and sterilize it by circulating steam at 115°C for 20 minutes.

Embodiment 2

[0056] Example 2 Preparation of Lincomycin-Gentamycin Compound Injection

[0057] Take 0.03% EDTA, add it to water for injection at 35°C, stir, and dissolve; respectively take gentamicin and lincomycin and add it into an appropriate amount of water for injection (35°C) and stir. Take 0.2% anhydrous sodium bisulfite and add it into the liquid medicine, and stir. Adjust the pH of the solution to 4.0 with hydrochloric acid solution, and fix the solution with water for injection. Add 0.2% needle-use activated carbon (25° C.) and stir for 20 minutes. Filter through 0.45um and 0.22um microporous membranes until clear. Nitrogen filling, steam sterilization at 115°C for 30 minutes.

Embodiment 3

[0058] Example 3 Preparation of Lincomycin-Gentamycin Compound Injection

[0059] Take 0.04% EDTA, add it to water for injection at 25°C, stir, and dissolve; respectively take gentamicin and lincomycin and add an appropriate amount of water for injection (25°C) and stir. Add 0.15% anhydrous sodium bisulfite into the liquid medicine, and stir. Adjust the pH of the solution to 6.0 with hydrochloric acid solution, and fix the solution with water for injection. Add 0.1% needle-use activated carbon (25° C.) and stir for 20 minutes. Filter through 0.45um and 0.22um microporous membranes until clear. Fill it with nitrogen gas, and sterilize it by circulating steam at 115°C for 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com