Coating solution for forming insulating film with excellent corrosion resistance property and film close adhesion property and film intensity without chrome and a method for making the insulation film

A corrosion-resistant, chromium-coated technology, used in metal material coating processes, coatings, anti-corrosion coatings, etc., can solve problems such as deterioration, the inability of the film to show tightness, restrictions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

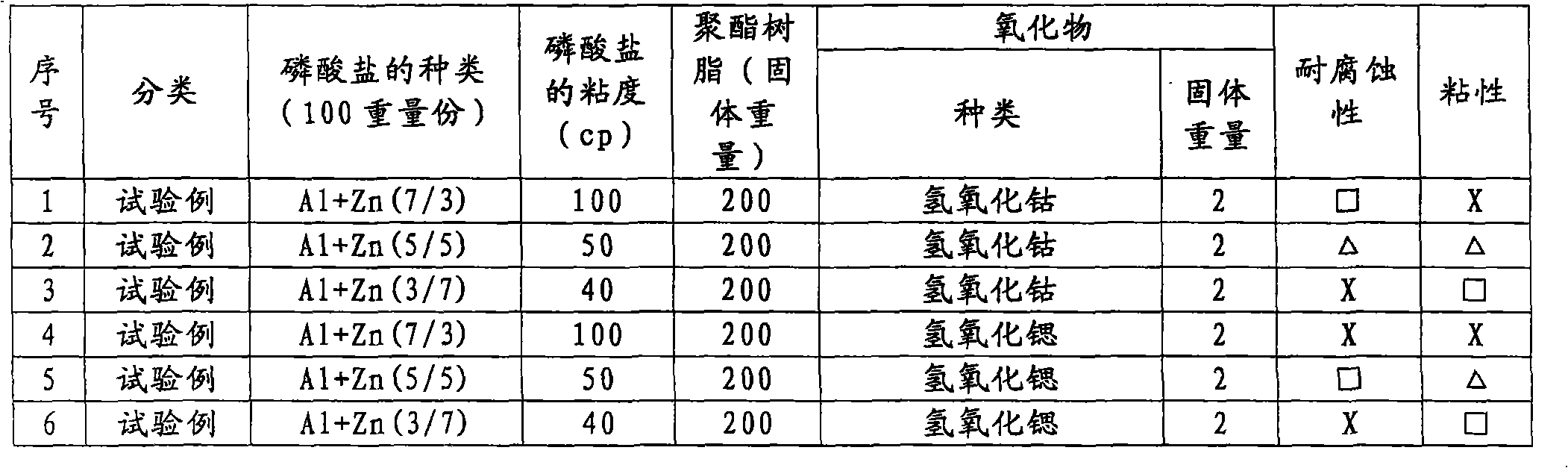

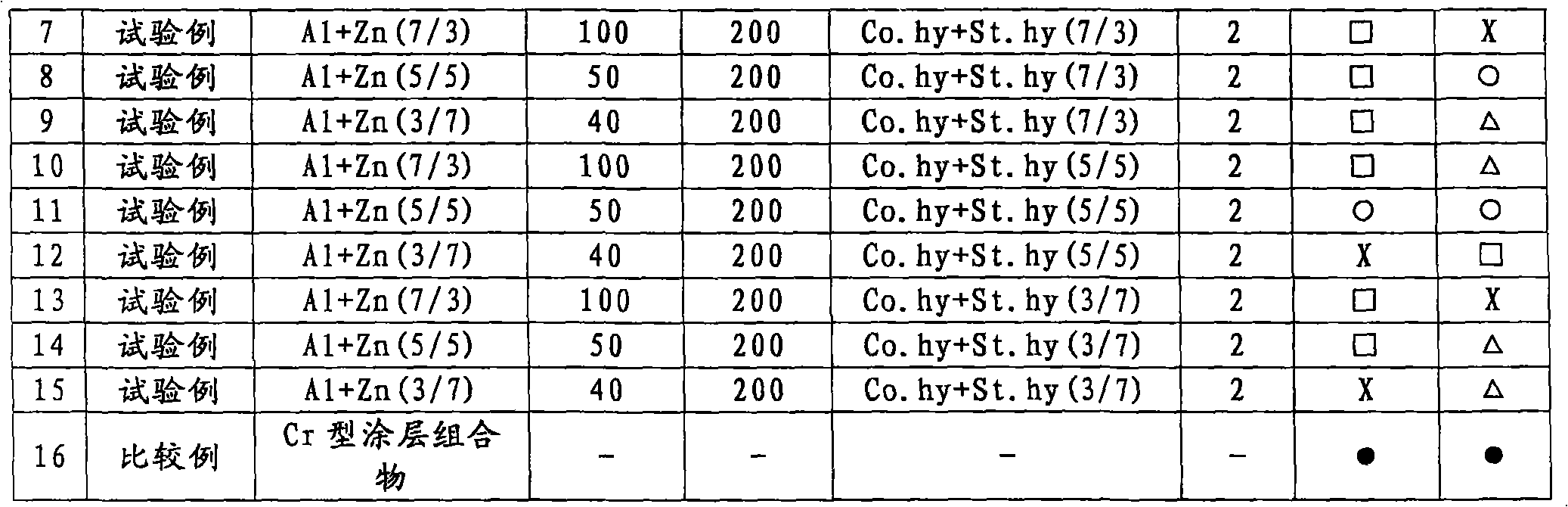

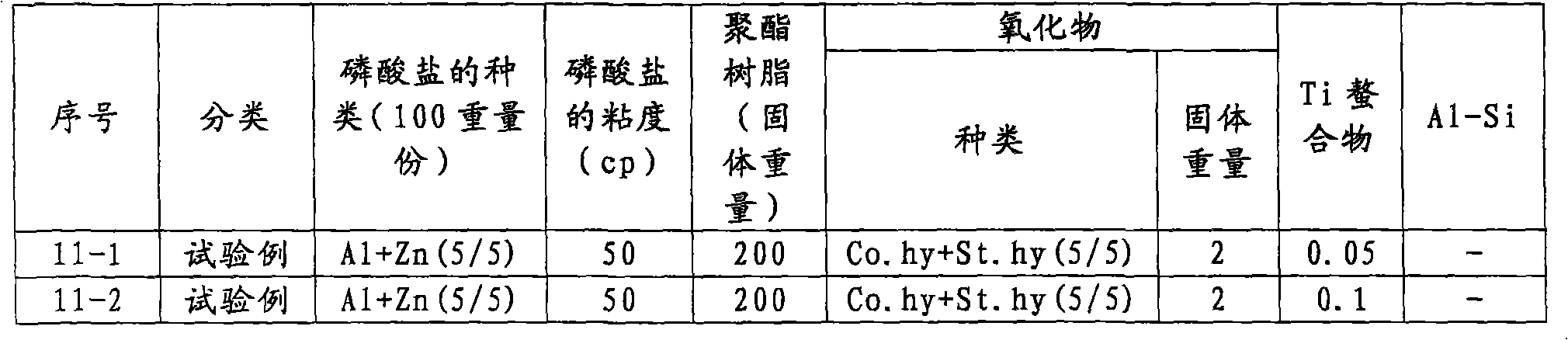

[0083] A non-oriented electrical steel sheet containing 0.1% by weight of silicon and having a thickness of 0.50 mm and an area of 120×60 mm was used as a sample, and various treatment liquids were applied at a rate of 0.5-6.0 g / m using a coating bar. 2 The amount coated on the sample.

[0084] Subsequently, the samples treated in the described method were dried at a temperature of 650° C. for several hours and then air-cooled.

[0085] Afterwards, in order to evaluate the characteristics of the samples, at 100% N 2 The sample was heat-treated at 750°C for 2 hours in the atmosphere to implement the stress relief annealing (SRA) process. The insulation performance of the sample was evaluated by measuring the current value when a voltage of 0.5V and a current of 1.0A were applied under a pressure of 300PSI. The adhesion Evaluated by measuring the minimum diameter of the arc when the sample forms an arc with a diameter of 10, 20, and 30 to 100 mm respectively and then bent at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com