Barium-titanium organic composite emulsion and application thereof for preparing external thermal insulation finishing mortar

A compound emulsion and organic technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem that the mortar's compressive and anti-bending performance and water and crack resistance performance cannot meet the requirements of art decoration, quality and Potential safety hazards, high cost and other issues, to achieve excellent protection performance, improve construction efficiency, increase compressive and flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

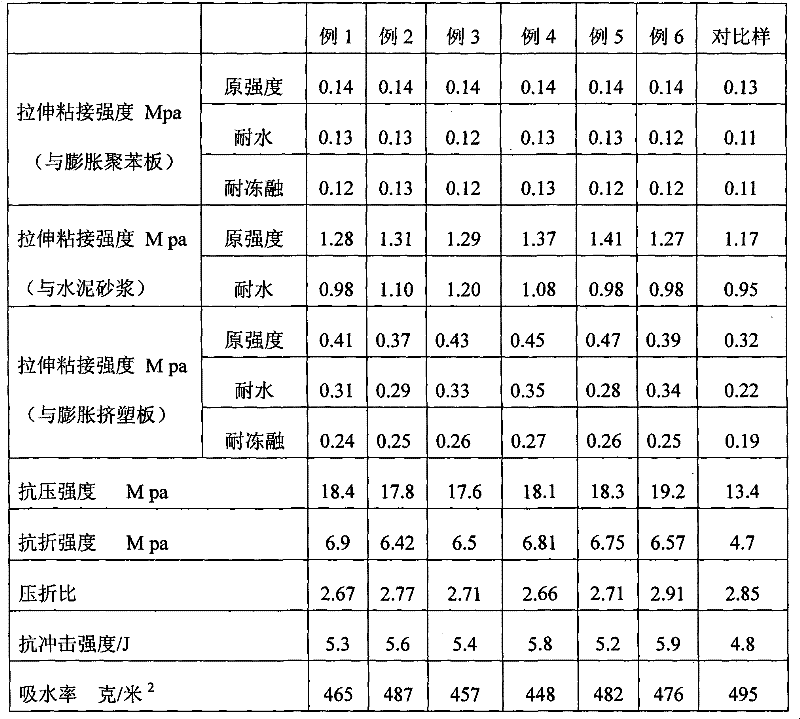

Examples

Embodiment 1

[0035] 1200 grams of cement, 2700 grams of quartz sand, 12 grams of hydroxyethyl cellulose ether, 12 grams of calcium formate, 4 grams of starch ether, 8 grams of defoamer, 8 grams of water reducing agent, 12 grams of plasticizer, thixotropic lubrication 8 grams of agent, 20 grams of wood fiber, 1200 grams of barium-titanium organic composite emulsion and 200 grams of water are stirred and mixed to obtain the artistic modeling class plastering mortar composition;

[0036] Its preparation method of described barium-titanium organic composite emulsion comprises the steps:

[0037] a) In the reactor, by weight, add 6 parts of rutile type 50 nanometer grade titanium dioxide, add 40 parts of deionized water, stir for 30 minutes, then add 1.5 parts of grafted gelatin, and the pH value is controlled at 5.5 (with ammonia water Regulate), be heated to 70 ℃, stirrer rotating speed is 180 rev / mins, with the barium nitrate solution 15 parts of weight concentration 20% and the ammonium sul...

Embodiment 2

[0042]1400 grams of cement, 2500 grams of quartz sand, 9 grams of hydroxyethyl cellulose ether, 9 grams of calcium formate, 4 grams of starch ether, 12 grams of foaming agent, 12 grams of water reducing agent, 8 grams of plasticizer, thixotropic lubrication 12 grams of agent, 16 grams of wood fiber, 1100 grams of barium-titanium organic composite emulsion and 250 grams of water were stirred and mixed to obtain an artistic modeling class plastering mortar composition.

[0043] Its preparation method of described barium-titanium organic composite emulsion comprises the steps:

[0044] a) In the reactor, calculate by weight. Add 8 parts of rutile-type 70 nanometer titanium dioxide, add 50 parts of deionized water, stir for 30 minutes, then add 3 parts of grafted gelatin, and control the pH value at 6 (with ammonia water Regulate), be heated to 80 ℃, the mixer rotating speed is 180 revs / min, drop simultaneously with 20 parts of barium nitrate solution of 15% by weight concentratio...

Embodiment 3

[0049] 1600 grams of cement, 2300 grams of quartz sand, 6 grams of hydroxyethyl cellulose ether, 6 grams of calcium formate, 2 grams of starch ether, 6 grams of foaming agent, 6 grams of water reducing agent, 6 grams of plasticizer, thixotropic lubricant 6 grams, 12 grams of wood fiber, 1000 grams of barium-titanium organic composite emulsion emulsion and 300 grams of water were stirred and mixed to obtain an artistic modeling class plastering mortar composition.

[0050] A) its preparation method of described barium-titanium organic composite emulsion comprises the steps:

[0051] In the reaction kettle, by weight, add 7 parts of rutile type 90 nanometer titanium dioxide, add 45 parts of deionized water, stir for 30 minutes, then add 2.5 parts of grafted gelatin, and control the pH value at 6.5 (adjusted with ammonia water) , heated to 75°C, the speed of the mixer is 180 rpm, 15 parts of barium nitrate solution with a weight concentration of 10% and 15 parts of an ammonium su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com