Method for expanding tobacco shred

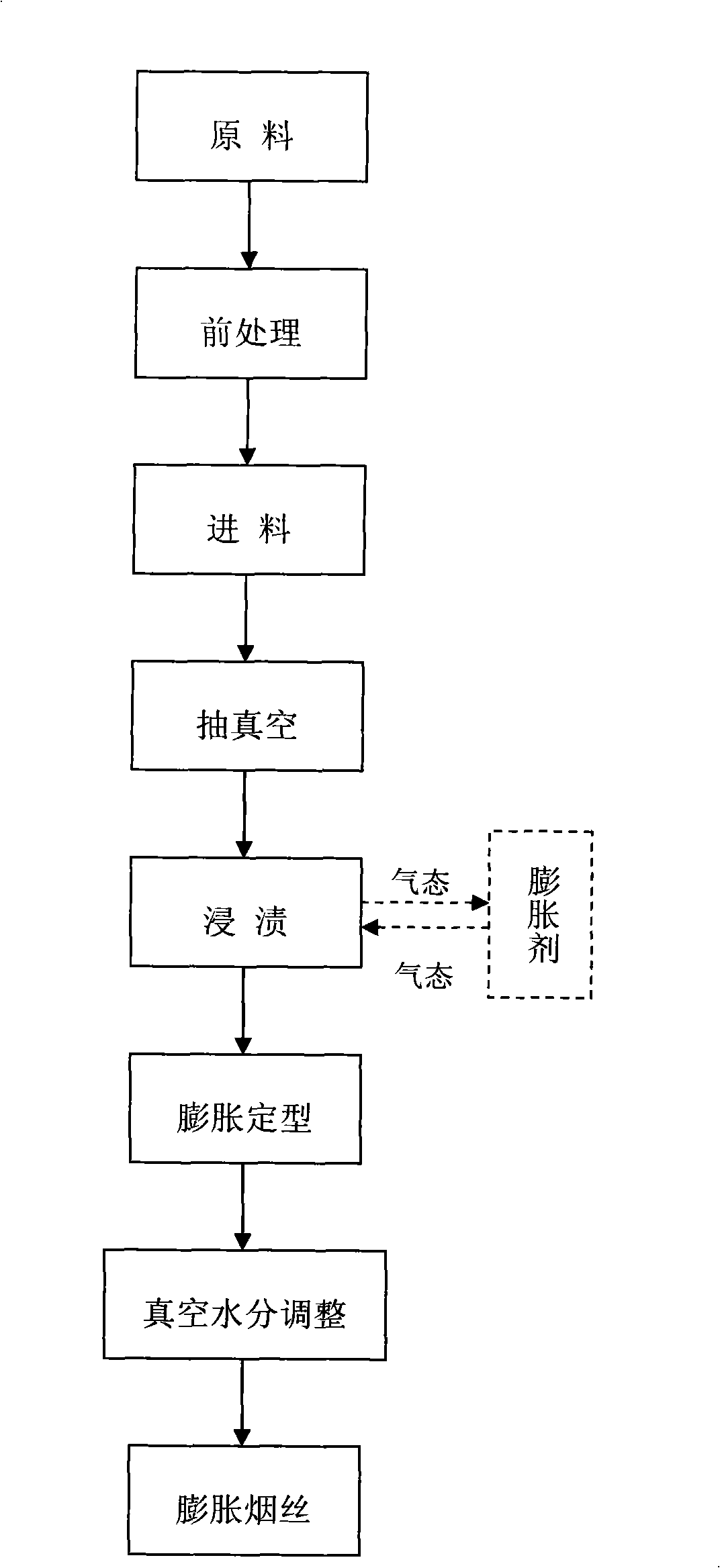

A technology for expanding shredded tobacco and shredded tobacco is applied in the field of expanding shredded tobacco, which can solve the problems of low safety, low expansion rate, large technical loss, etc., and achieve the effects of simple system equipment, good expansion effect and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Pre-treat the cut tobacco raw material so that the moisture content of the cut tobacco is controlled at about 18%, preheat the container to 20°C to 21°C, put the cut tobacco in the container for decompression treatment, and stop the decompression when the pressure in the container is reduced to 3kPa. Introduce dimethyl ether vapor at 21°C, and when the pressure rises to 538kPa, keep the pressure for 20 minutes to fully impregnate the shredded tobacco with dimethyl ether, then reduce the pressure in the container to close to atmospheric pressure without destroying the micropore structure of the shredded tobacco cells, and release Excess dimethyl ether vapor. Inject water vapor into the container to quickly raise the temperature in the container to 135°C, stop injecting water vapor, and quickly reduce the pressure in the container to 50kPa after expansion and setting for 55s, and recover the residual dimethyl ether vapor at the same time, continue to depressurize to 3kPa, ...

Embodiment 2

[0021] Pre-treat the cut tobacco raw material, control the moisture content of the cut tobacco at about 5%, preheat the container to 38°C, put the shredded tobacco in the container for decompression treatment, stop the decompression when the pressure in the container is reduced to 2.5kPa, and inject 35 ℃ dimethyl ether vapor, when the pressure rises to 866kPa, keep the pressure for 10min, and then reduce the pressure in the container to 110kPa without destroying the micropore structure of the cut tobacco cells, and release excess dimethyl ether vapor at the same time. Inject heated nitrogen gas into the container, quickly raise the temperature inside the container to 140°C, stop injecting nitrogen gas, and quickly reduce the pressure in the container to 50kPa after expanding and setting for 20s, and recover the residual dimethyl ether vapor at the same time, continue to reduce the pressure to 3kPa, Carry out vacuum readjustment to shredded tobacco, adjust moisture to 12%~13%, c...

Embodiment 3

[0023] Pre-treat the cut tobacco raw material, control the moisture content of the cut tobacco at about 22%, preheat the container to 44°C to 45°C, put the cut tobacco in the container for decompression treatment, stop the decompression when the pressure in the container is reduced to 2kPa, and pass Inject dimethyl ether vapor at 48°C, keep the pressure for 30 minutes when the pressure rises to 1010kPa, then reduce the pressure in the container to close to 115kPa without destroying the microporous structure of the cut tobacco cells, and release excess dimethyl ether vapor at the same time. Inject heated carbon dioxide gas into the container, quickly raise the temperature in the container to 100°C, stop injecting carbon dioxide gas, and quickly reduce the pressure in the container to 50kPa after expanding and setting for 60 seconds, and recover the residual dimethyl ether vapor at the same time, continue to depressurize to 3kPa, carry out vacuum readjustment to shredded tobacco,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com