Knitting method of needle-through paper rope

A technology for passing paper and paper strips, applied in the field of knitted fabrics, can solve the problems of small contact surface, uneven shape, long occupation time, etc., and achieve the effect of good expansion effect, uniform shape, and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

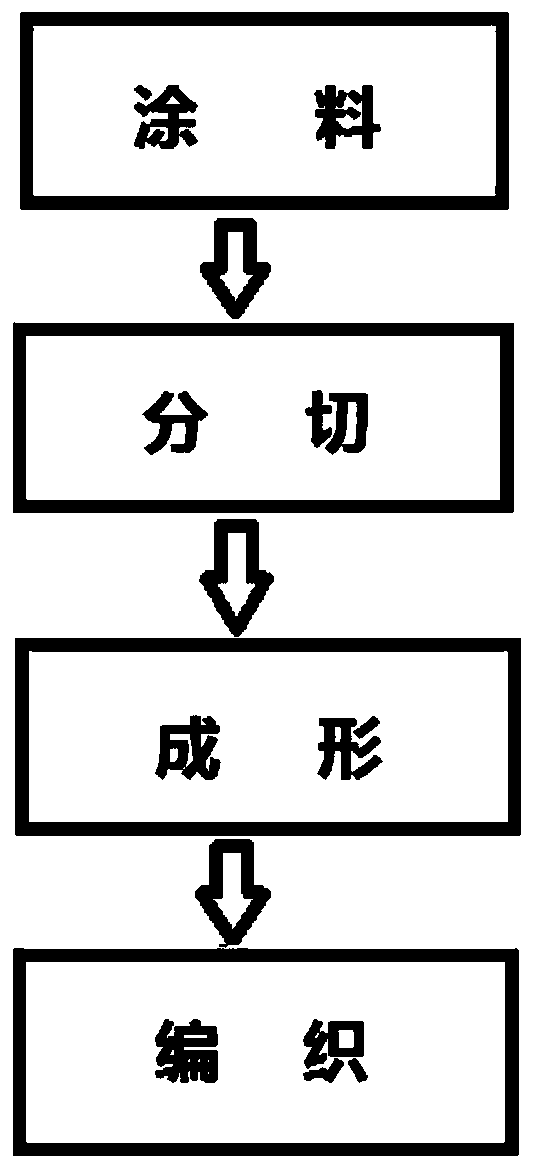

[0022] Such as figure 1 , 5 , as shown in 6,

[0023] S1 coating: Apply the softener evenly on the upper, lower, left, and right sides of the paper;

[0024] S2 Slitting: Slitting the paper coated with softener into the required width through a paper splitter or paper cutter;

[0025] S3 forming: extruding or pultruding the slit paper strips into a cross-section of a thread and folding it into a circular yarn at a point;

[0026] S4 weaving: knitting the formed yarn directly into a needle-through paper rope or a needle-through paper rope with a rope core.

[0027] The beneficial effect of adopting the first embodiment is:

[0028] The yarn is pultruded to form a cross-section similar to a thread folded into a circle at a point. The yarn has a force to leave its axis under the action of its fiber elasticity, so the needle-through paper rope woven has a relatively strong Good swelling effect, softer touch.

[0029] The yarn is only folded towards its axis, and the stress o...

Embodiment 2

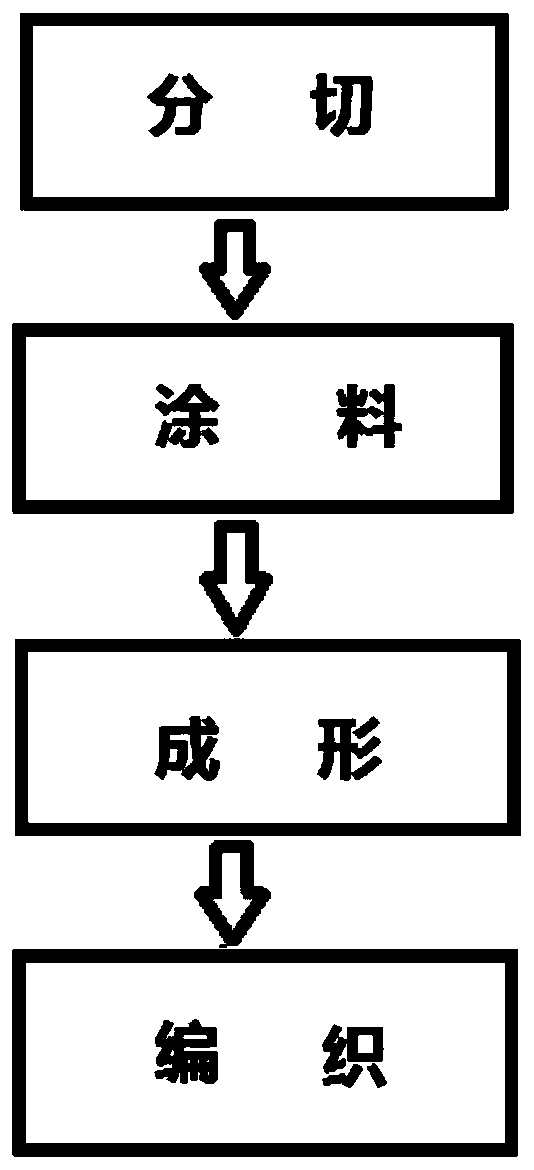

[0034] Such as figure 2 , 5 , as shown in 6,

[0035] S2 slitting: use a paper splitter or paper cutter to cut the paper into the required width;

[0036] S1 Coating: Apply the softener evenly on the upper, lower, left, and right sides of the paper through the coating equipment after cutting the paper strips;

[0037] S3 forming: extruding or pultruding the paper strip coated with softener to form a yarn whose cross section is one line and folded into a circle at one point;

[0038] S4 weaving: weaving the formed yarn directly into a needle-through paper rope or a needle-through paper rope with a rope core;

[0039] Adopting the second embodiment possesses the same technical effect as the first embodiment, and compared with the first embodiment, the two opposite sides of the cut paper are coated with softening agent.

Embodiment 3

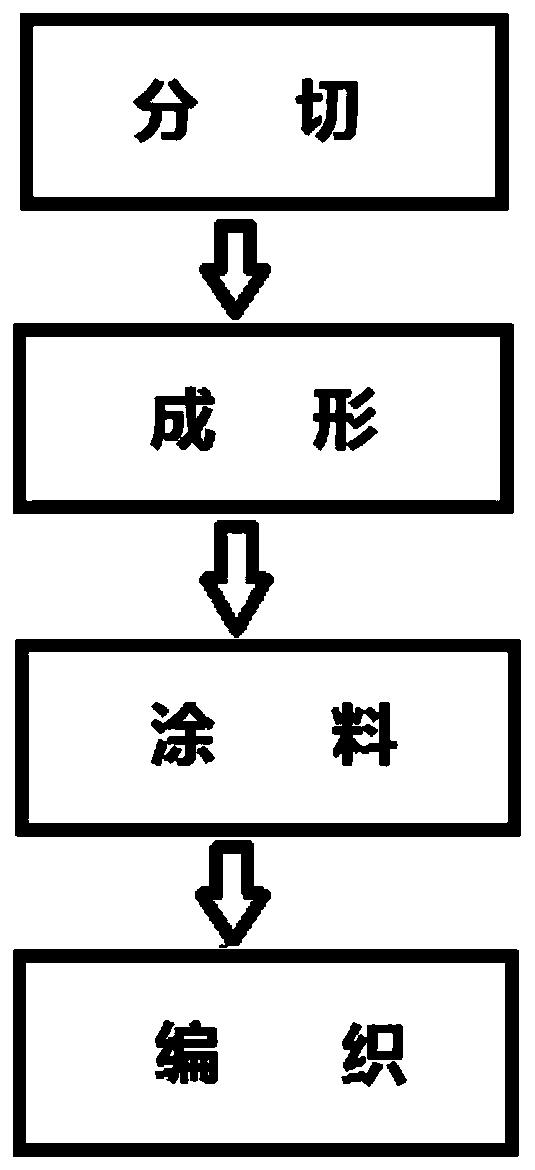

[0041] Such as image 3 , 5 , as shown in 6,

[0042] S2 slitting: use a paper splitter or paper cutter to cut the paper into the required width;

[0043] S3 forming: extruding or pultruding the slit paper strips into a cross-section of a thread and folding it into a circular yarn at a point;

[0044] S1 coating: apply the softener evenly on the side of the yarn through the coating equipment;

[0045] S4 weaving: knitting the yarn coated with softener directly into a needle-through paper rope or a needle-through paper rope with a rope core.

[0046] Adopting the third embodiment has the same technical effect as the first embodiment. Compared with the first embodiment, this embodiment only needs to apply softener to the side of the formed yarn, and can achieve the same hand feeling. The use of softening agent can be reduced under the length of the yarn, thereby achieving the effect of reducing production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com