Conductive film forming method, thin film transistor, panel with thin film transistor and thin film transistor manufacturing method

A technology of thin film transistors and conductive films, applied in semiconductor/solid-state device manufacturing, transistors, electric solid-state devices, etc., can solve the problems of resistive hillock patience and low adhesion, and achieve high adhesion and contact The effect of low resistance and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0086]

[0087]As the main target 11 , a copper (purity: 99.9 at % or more) target with a diameter of 7 inches was used, and as the sub-target 12 , a target made of Ti was used.

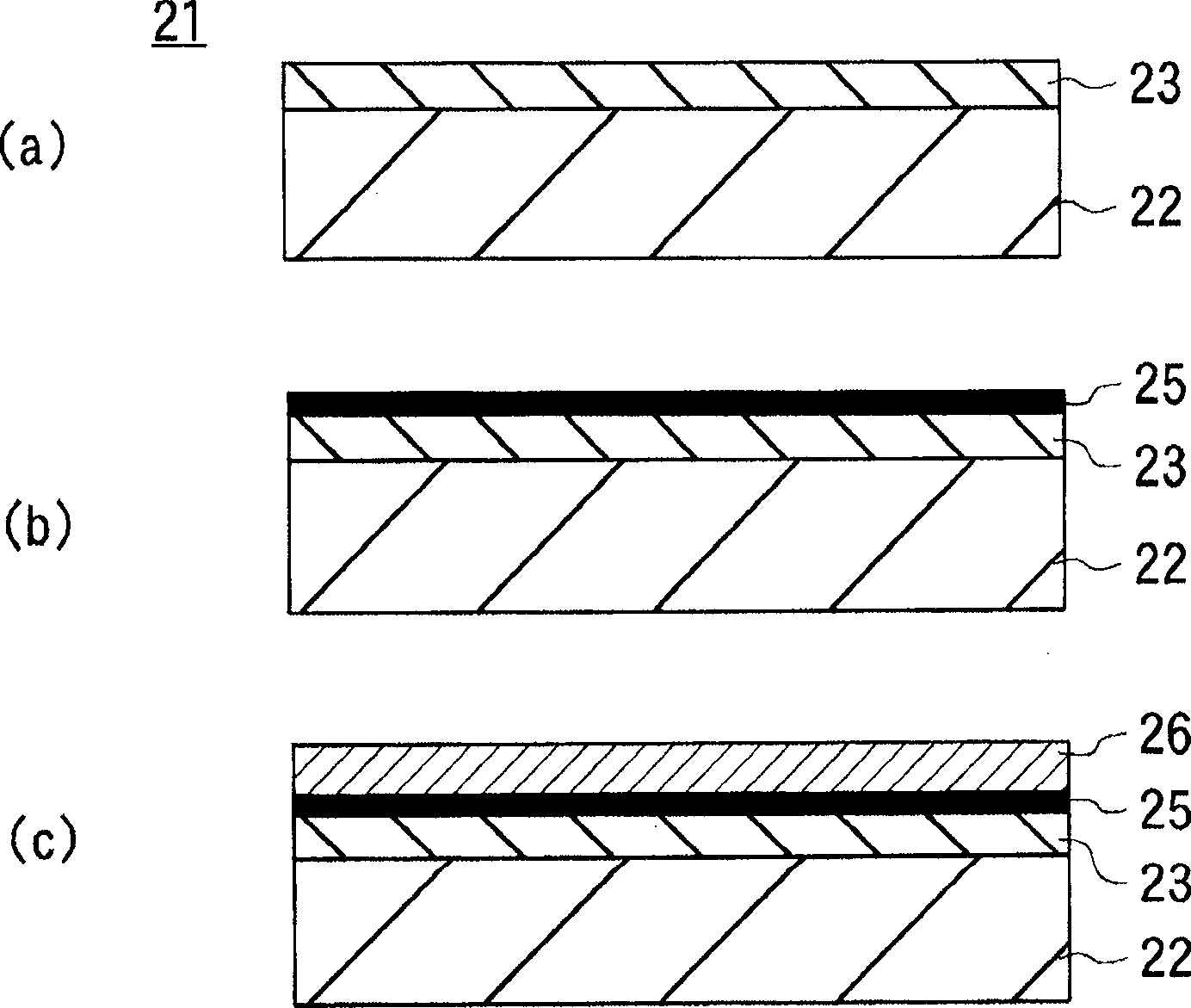

[0088] The conductive film 25 was formed on the surface of the glass substrate by changing the Ti content in the conductive film 25 , the partial pressure of nitrogen gas during film formation, and the heating temperature (post-annealing temperature) during annealing treatment, and 125 kinds of test pieces were produced.

[0089] Further, except that the sub-target 12 was changed to a target made of Zr, the conductive film 25 was formed on the surface of the glass substrate by the same procedure as above, and 125 kinds of test pieces were produced.

[0090] In addition, the film forming conditions of each conductive film 25 are: the target film thickness of the conductive film 25 is 300 nm, the sputtering gas is Ar gas, and the total pressure inside the first film forming chamber 2 is 0.4 Pa. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com