Liquid nitrogen straightly-spraying cold treatment equipment

A cold treatment, direct-injection technology, applied in lighting and heating equipment, refrigerators, refrigeration and liquefaction, etc., can solve the problems of difficult cryogenic treatment, human injury, environmental protection, etc., to save cold source consumption and improve control. Accuracy and the effect of saving cold sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

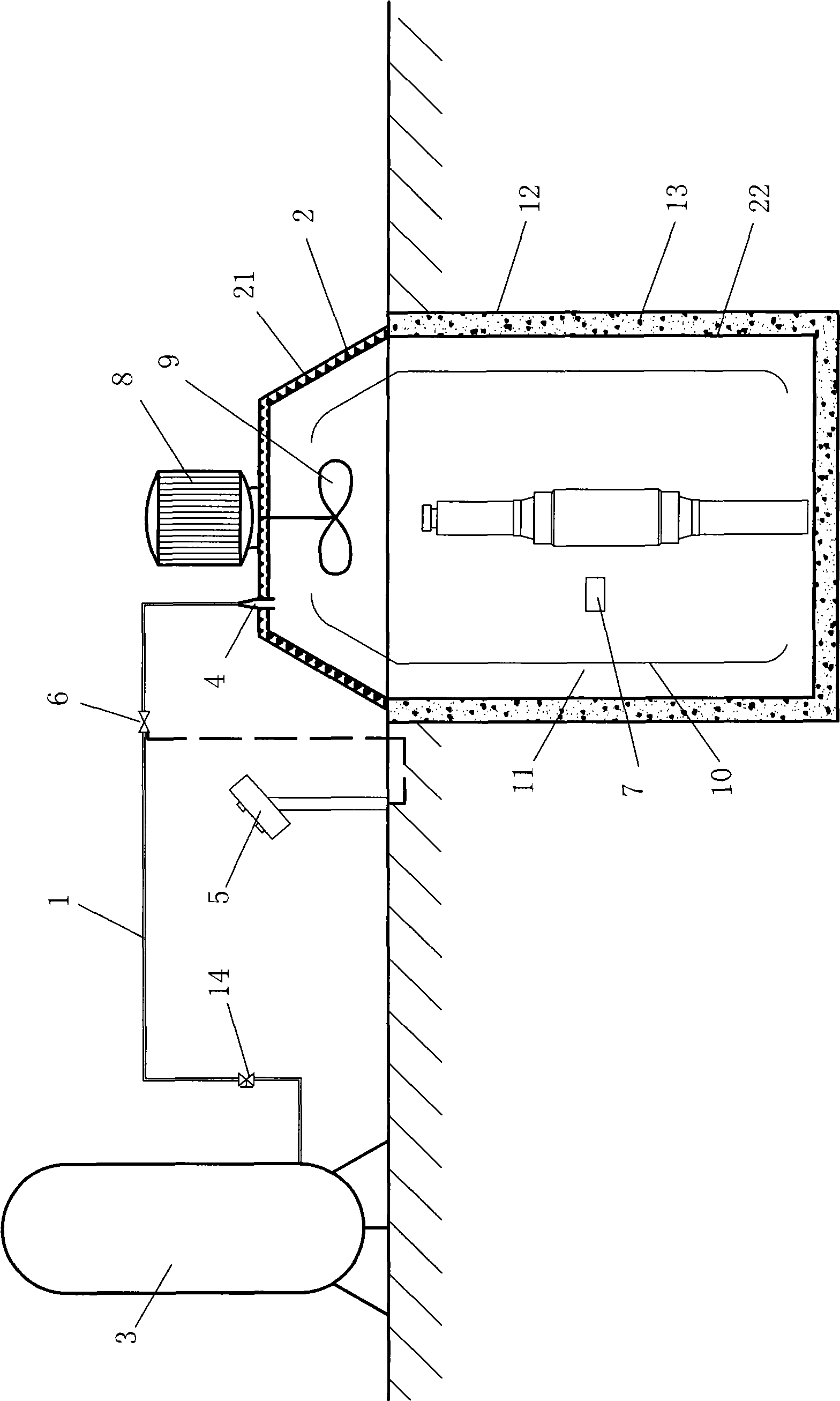

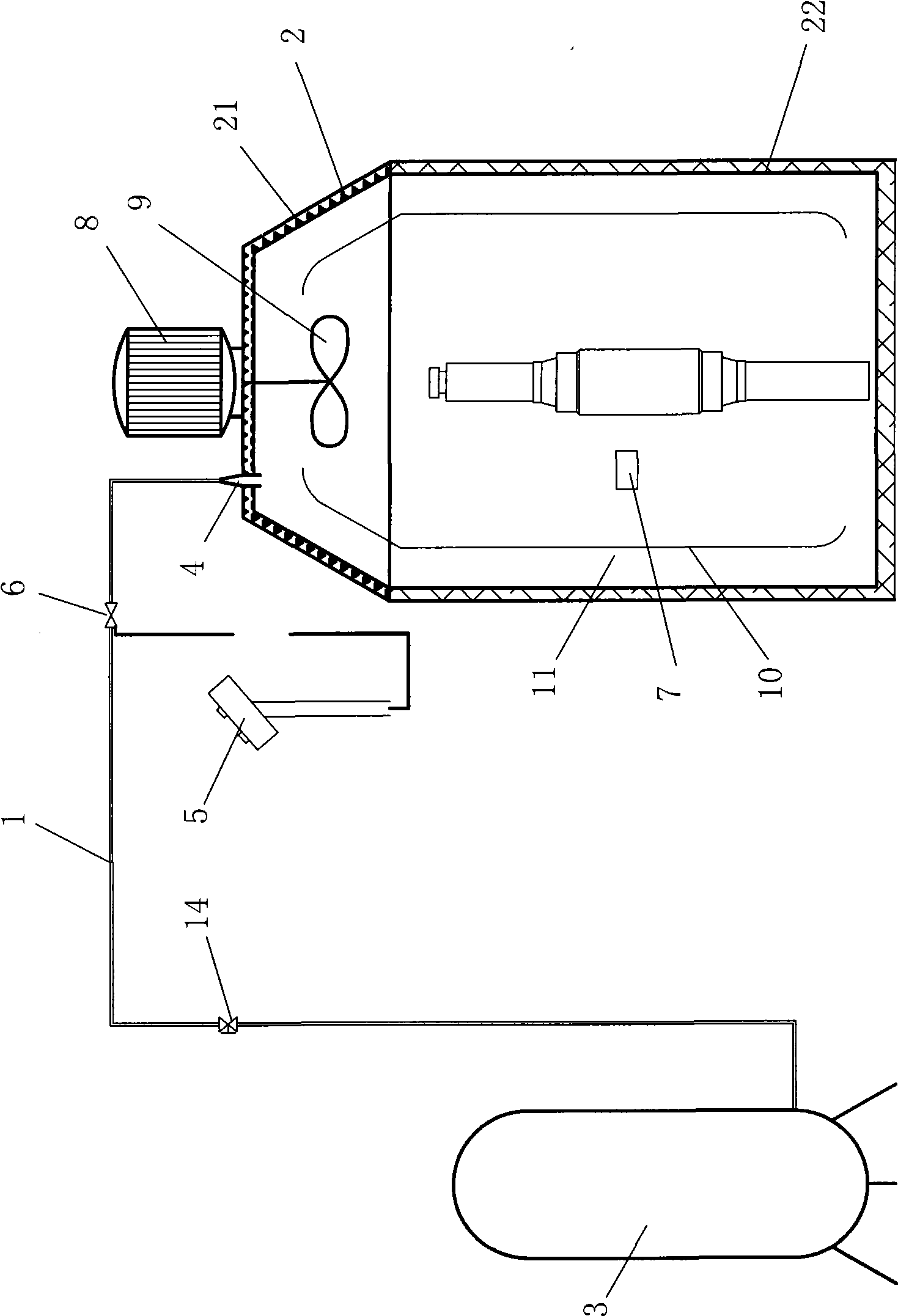

[0023] Example: such as figure 1 and figure 2 As shown, a liquid nitrogen direct injection type cold treatment equipment includes a processing container 2 and a liquid nitrogen tank 3 communicated through a delivery pipeline 1, a liquid nitrogen nozzle 4 is provided at the end of the delivery pipeline 1 connected to the processing container 2, and the delivery pipe A solenoid valve 6 controlled by a control system 5 is provided on the road 1, a temperature measuring sensor 7 is provided in the processing container 2, and the temperature measuring sensor 7 can carry out signal transmission with the control system 5; The fan 8 controlled by the control system 5 , the blades 9 of the fan 8 are located in the processing container 2 . During the working state, the temperature measuring sensor 7 transmits the temperature in the processing container 2 to the control system 5, and the control system 5 can conveniently realize the adjustment of the roll surface heat transfer coeffici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com