Cooling method for gain medium in solid laser and low interior heat solid laser

A solid-state laser, gain medium technology, used in lasers, laser parts, phonon exciters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

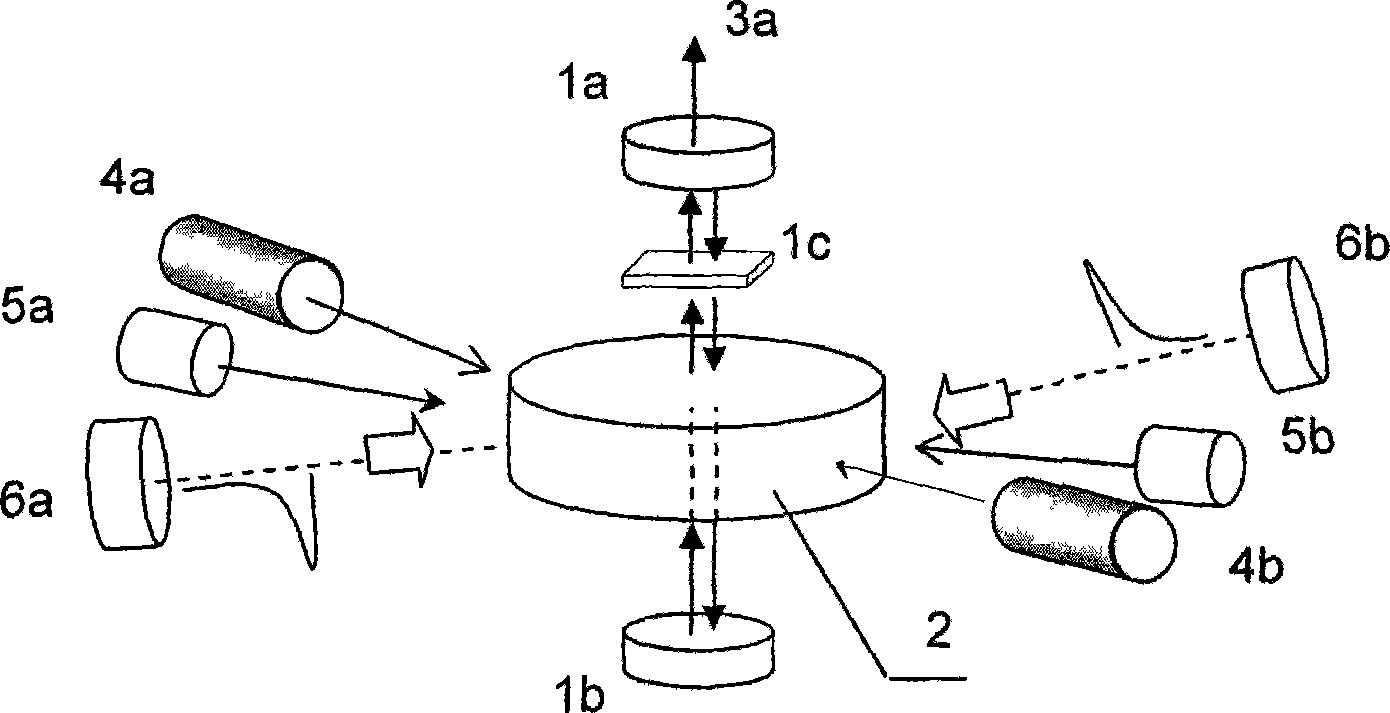

[0020] Example 1: Side-pumped chip low internal heat laser

[0021] control figure 1 : In a chip laser, a laser oscillating part and a laser cooling part are combined into one. The laser oscillating components include: gain medium 2, pump light sources 4a and 4b that generate population inversion, laser output mirror 1a, total reflection mirror 1b, and near-infrared laser output beam 3a. The laser cooling components include: cooling medium, main pumping light sources 5a, 5b, and auxiliary pumping (pulse) light sources 6a, 6b. The cooling medium of the laser cooling component is the gain medium 2, that is, the laser gain medium also serves as the laser cooling medium, and its doping method is divided into two basic types: single-component doping and dual-component doping.

[0022] 1. Laser gain medium doubles as cooling medium

[0023] The single-component doped gain medium is Yb 3+ : KGd(WO 4 ) 2 Crystal (hereinafter referred to as Yb 3+ : KGW), the typical value of ytt...

Embodiment 2

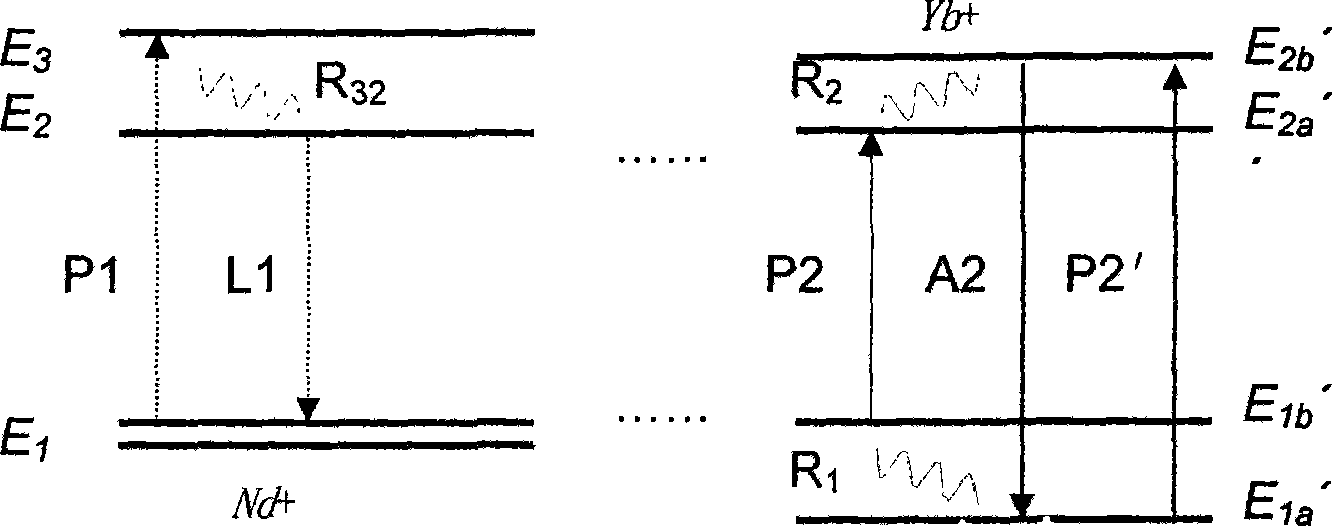

[0035] Example 2: Side-pumped bar-shaped laser with low internal heat

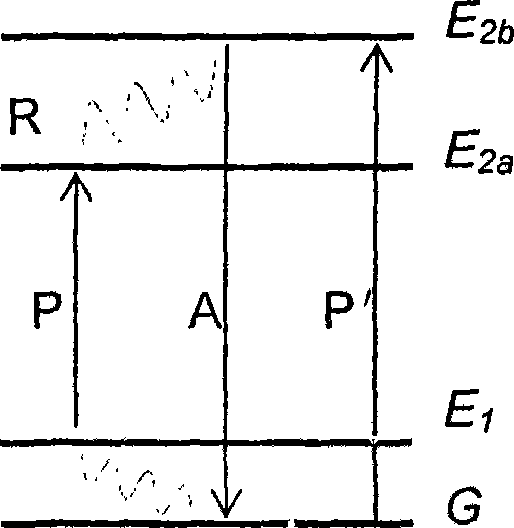

[0036] control Figure 4 : The bar laser is composed of laser oscillation and laser cooling. Laser oscillation components include: Yb or Nd-doped gain medium 2, pump light sources 4a, 4b that generate population inversion and resonant cavity (laser output mirror 1a, total reflection mirror 1b). The near-infrared laser output beam is shown in Figure 3. The laser cooling components include: cooling medium. Main pump light sources 5a, 5b, auxiliary pump (pulse) light sources 6a, 6b. The laser-cooled pump light source 5a, 5b pumps the medium 2 from the side, and the optical path is as follows: Figure 4 shown. The pump light source 5a, 5b cooperates with the light source 6a, 6b to induce superradiation and improve the cooling efficiency, such as figure 2 shown. Auxiliary pump beams (pulses) 6a, 6b for inducing superradiation are incident into the medium 2 from the side, so as to induce superradiation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com