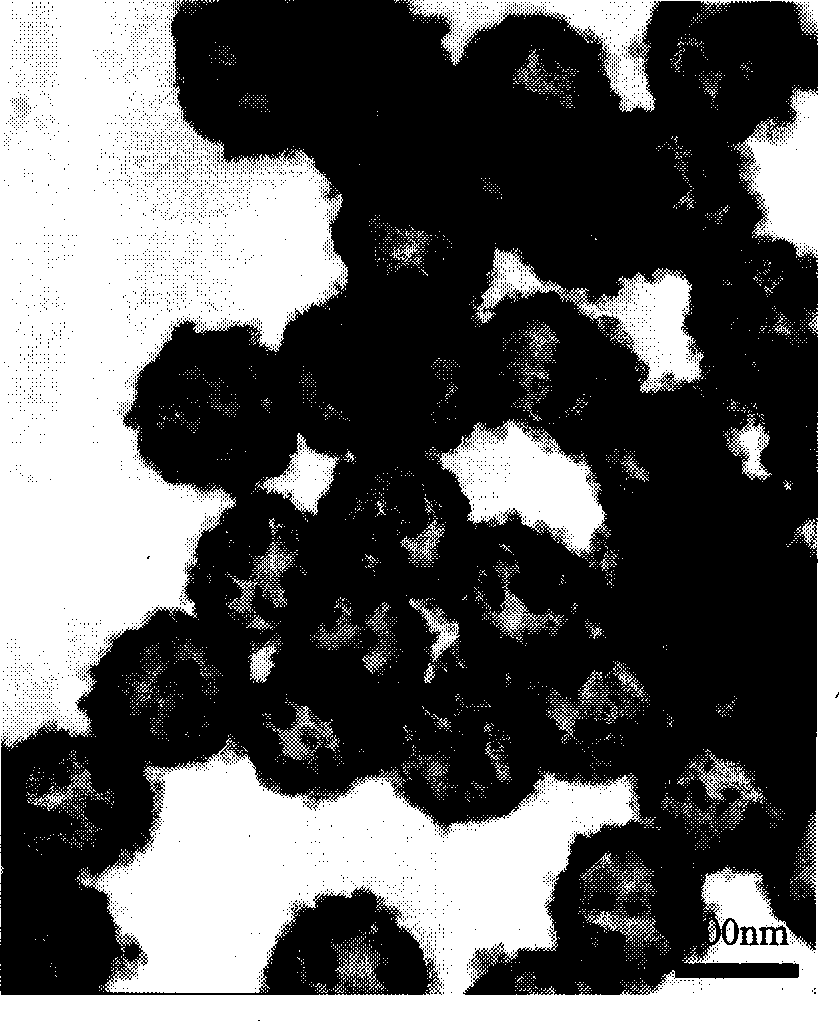

Hollow silicon dioxide/magnetic composite microsphere and its production method

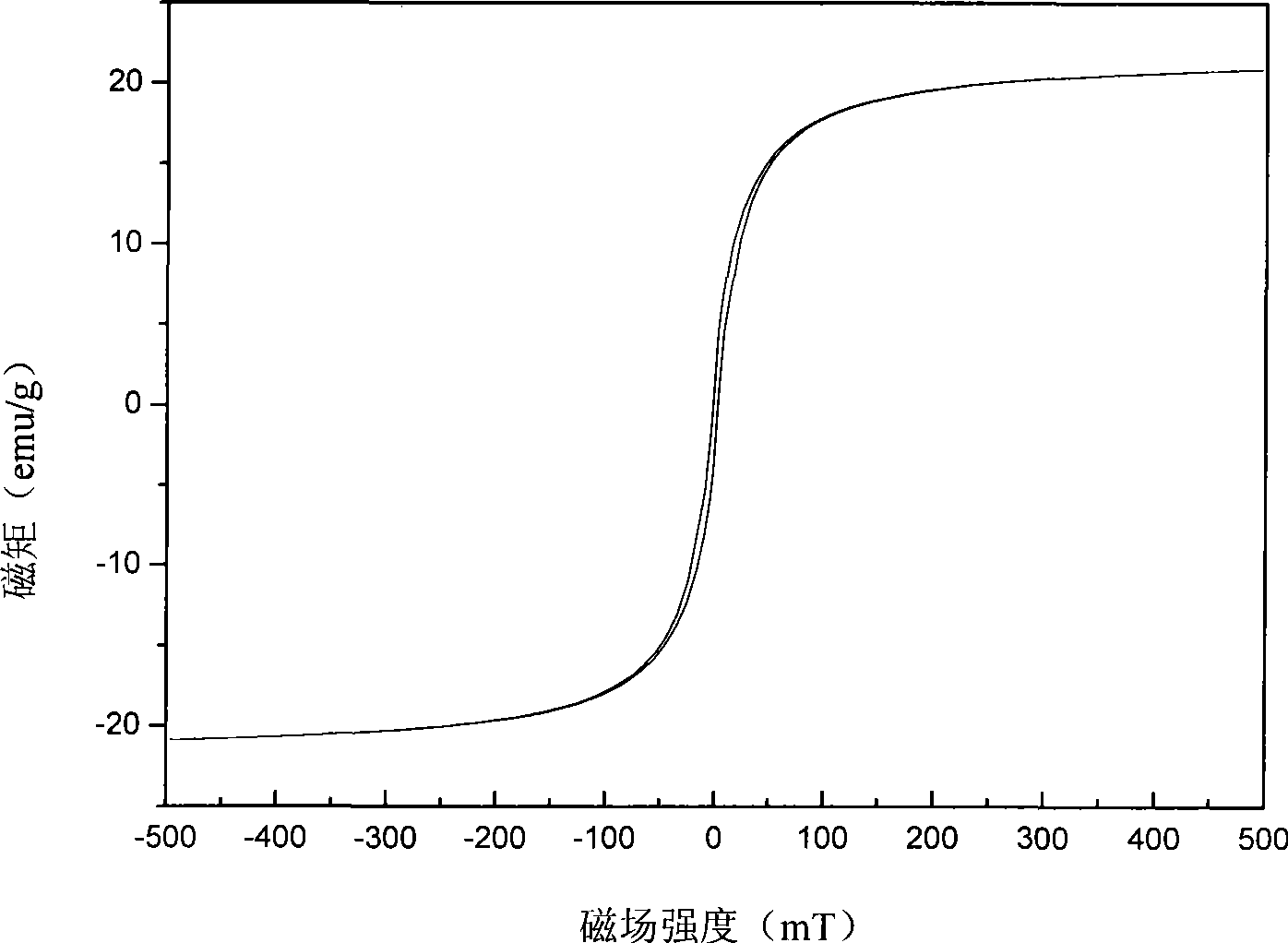

A technology of magnetic composite microspheres and silica, which is applied in the field of composite materials and functional materials, can solve the problems of uncoated magnetic particles, etc., and achieve the effects of good mechanical and chemical stability, excellent magnetic properties, and controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The ratio of raw materials used is as follows:

[0038] Component Weight percent (wt.%)

[0039]Hollow silica microspheres with sulfonic acid groups 100 parts

[0040] Water 40000 parts

[0041] Dispersant ethylene glycol 1000 parts

[0042] Oxidant H 2 o 2 40 copies

[0043] Ferric chloride hexahydrate 0 parts

[0044] 80 parts of ferrous sulfate heptahydrate

[0045] Hexamethylenetetramine 700 parts

[0046] Preparation of magnetic composite particles:

[0047] According to the above component ratios, the hollow silica microspheres with sulfonic acid groups are ultrasonically dispersed in the dispersion medium added with dispersant and oxidant to obtain sample a.

[0048] Add ferrous sulfate heptahydrate into a solution into the reaction vessel, add sample a, and stir for 0.5-1 hour; dissolve hexamethylenetetramine in deionized water to form a solution, slowly add it into the reaction vessel, and then Under the protection ...

Embodiment 2

[0050] The ratio of raw materials used is as follows:

[0051] Component Weight percent (wt.%)

[0052] Hollow silica microspheres with sulfonic acid groups 100 parts

[0053] Water 40000 parts

[0054] Dispersant polyethylene glycol 1000 parts

[0055] Oxidant Potassium Perchlorate 10 parts

[0056] Ferric chloride hexahydrate 110 parts

[0057] 60 parts of ferrous sulfate heptahydrate

[0058] Hexamethylenetetramine 700 parts

[0059] Preparation of magnetic composite particles:

[0060] According to the proportion of the above components, the hollow silica microspheres with sulfonic acid groups were ultrasonically dispersed in the dispersion medium added with dispersant and oxidant to obtain sample a.

[0061] Add ferric chloride hexahydrate and ferrous sulfate heptahydrate into a solution into a reaction vessel, add sample a, and stir for 0.5-1 hour; dissolve hexamethylenetetramine in deionized water to form a solution, and slowly add to After being placed in the r...

Embodiment 3

[0063] The ratio of raw materials used is as follows:

[0064] Component Weight percent (wt.%)

[0065] Hollow silica microspheres with sulfonic acid groups 100 parts

[0066] Water 40000 parts

[0067] Dispersant sodium dodecylbenzene sulfonate 1000 parts

[0068] Oxidant ammonium persulfate 50 parts

[0069] Ferric chloride hexahydrate 0 parts

[0070] Nickel sulfate 90 parts

[0071] Aniline 700 parts

[0072] Preparation of magnetic composite particles:

[0073] According to the proportion of the above components, the hollow silica microspheres with sulfonic acid groups were ultrasonically dispersed in the dispersion medium added with dispersant and oxidant to obtain sample a.

[0074] Make a solution of nickel sulfate into the reaction container, add sample a, and stir for 0.5-1 hour; dissolve aniline in deionized water to make a solution, slowly add it into the reaction container, and then raise the temperature to 90°C under the protection of nitrogen atmosphere. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com