Optical bicomponent antiglossing pigment and preparation thereof

A matting coating, two-component technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of insufficient adhesion of one component, poor aging resistance of three components, poor matting performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

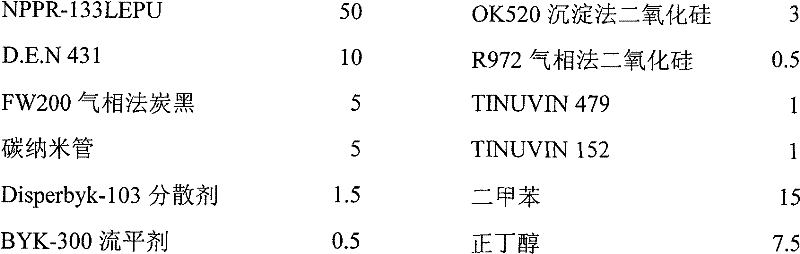

[0025] Embodiment 1 (weight ratio)

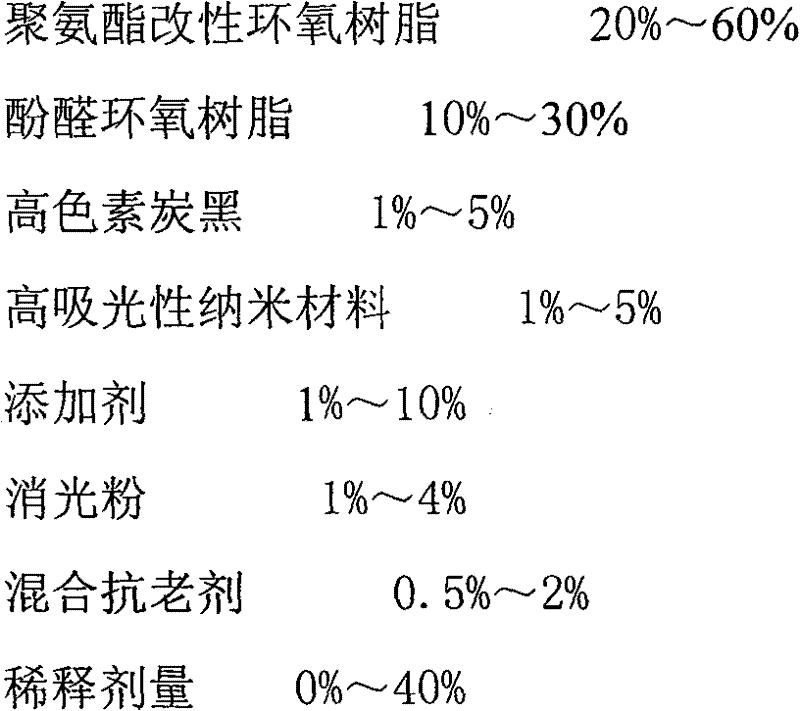

[0026] Component A formula:

[0027]

[0028] Component B formula:

[0029] Polyamide 651 60 DB-602 Silane coupling agent 3

[0030] Ancamine 1561 20 n-Butanol 17

[0031] When preparing, first add NPPR-133LEPU, D.E.N 431, FW200, carbon nanotubes, Disperbyk-103 dispersant, 1 / 2 toluene, 1 / 2 n-butanol to a sand mill and grind for 3 hours. Take out the ground color paste and put it into a high-speed disperser, add the remaining materials of component A under high-speed stirring, disperse and mix evenly, filter, discharge, sub-package, and use it as component A for later use; polyamide 651, Ancamine 1561 , DB-602, and n-butanol are placed in the reactor and stirred evenly, and used as component B for later use. When in use, mix evenly according to A:B=3:1 (weight ratio) and then brush it on the burr of the optical element. It will be cured after 24 hours at room temperature or 2 hours at 80°C. The visible light reflectance is ≤3%, and th...

Embodiment 2

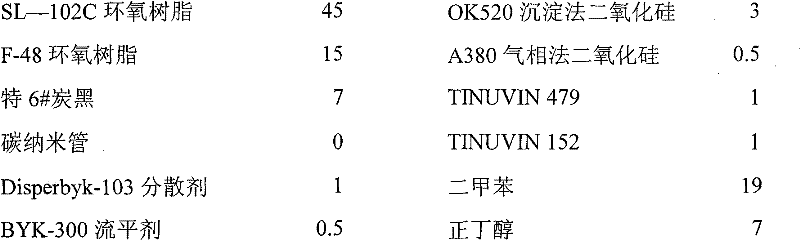

[0032] Embodiment 2 (weight ratio)

[0033] Component A formula:

[0034]

[0035] Component B formula:

[0036] 593 epoxy curing agent 85 absolute alcohol 3

[0037] DB-602 silane coupling agent 5 ethyl acetate 7

[0038] When preparing, first add SL-102C, F-48, special 6# carbon black, carbon nanotubes, Disperbyk-103 dispersant, 1 / 2 xylene, 1 / 2 n-butanol to a sand mill and grind for 3 hours . Take out the ground color paste and put it into a high-speed disperser, add other materials remaining in component A under high-speed stirring, disperse and mix evenly, filter, discharge, pack, and use it as component A for later use; mix 593 epoxy curing agent, Put DB-602 silane coupling agent, absolute ethanol, and ethyl acetate in a reaction kettle and stir to mix evenly, and use it as component B for later use. When in use, mix evenly according to A:B=3:1 (weight ratio) and then brush it on the burr of the optical element. After curing for 24 hours at room temperature or 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com