A kind of preparation method of self-dulling emulsion with oily matting resin as core

A matting resin and self-matting technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as easy breakage and shedding, corrosion resistance and scratch resistance, decreased bending resistance performance characteristics, and surface whitening. , to achieve the effects of transparent matting, excellent film-forming properties, and soft touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

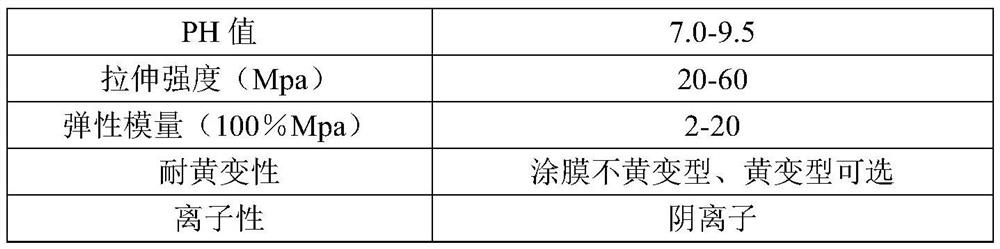

Image

Examples

Embodiment 1

[0050] A method for preparing a self-dulling emulsion with an oily matting resin as a core, comprising the following steps:

[0051] S1. Preparation of oil-based matting resin: In a strong polar water-soluble solvent, react crystalline polyester polyol with crystalline diisocyanate to prepare the first-stage product to generate crystalline polyurethane; in the second stage, add binary Alcohol, use the residual -NCO to graft silicone polyols, continue to react, and use the incompatibility between polar polyurethane and non-polar silicone to generate oily matting resin;

[0052] S2. Preparation of low-viscosity water-based prepolymer: adopt low-viscosity EO-containing polyol, and add glycol, carboxyl glycol, bismuth catalyst, antioxidant and IPDI, and react to obtain low-viscosity water-based prepolymer;

[0053] S3. Co-emulsification: Add the oil-based matting resin of S1 to the low-viscosity water-based prepolymer of S2, and add a salt-forming agent and a chain extender for em...

Embodiment 2

[0061] A self-dulling emulsion prepared by the following preparation method:

[0062] (1) Preparation of polymer oily matting resin

[0063] Take DMF 200g, PCD3000 150g and H 12 MDI13g, react at 80°C for 2 hours, add 1,4-BDO 27g, H 12 MDI 78g, DMF 100g and SF8427 50g, and gradually add H 12 MDI 5.2g to increase the viscosity, finally add DMF434g, adjust the viscosity to 3000-5000mPa.S, non-volatile content 30±2%, average molecular weight about 40000.

[0064] (2) Preparation of low-viscosity water-based prepolymer

[0065] Take 174g of IPDI, 180g of Ymer N120 (Pastor, Sweden), 18g of DMPA, 20g of 1,4-BDO, 1g of K24 (bismuth catalyst), 1g of I1010 (antioxidant), put them into a 500mL three-necked flask, and heat up to 90-95 React at ℃, cool down when the NCO value drops to 1.2-1.3mmol / g, and set aside.

[0066] (3) Preparation of solid self-dulling emulsion

[0067] Take 100g of low-viscosity water-based prepolymer, 100g of polymer oil-based matting resin, and 3g of TEA a...

Embodiment 3

[0069] A self-dulling emulsion prepared by the following preparation method:

[0070] (1) Preparation of polymer oily matting resin

[0071] Take 200g of DMF, 150g of PBA3000 and 12.5g of MDI100, react at 80°C for 2 hours, add 27g of 1,4-BDO, 75g of MDI100, 100g of DMF, 50g of SF8427 (molecular weight 2000, dihydroxyl), gradually add 5g of MDI100 to increase the viscosity, and finally add DMF 434g, adjusted viscosity 3000-5000mPa.S, non-volatile content 30±2%, average molecular weight about 30000.

[0072] (2) Preparation of low-viscosity water-based prepolymer

[0073] Take 174g of IPDI, 180g of Unisafe C-1100 (NOF Corporation), 18g of DMPA, 20g of 1,4-BDO, 1g of K24 (bismuth catalyst) and 1g of I1010 (antioxidant) into a 500ml three-necked flask, and heat up to 85-90°C React, cool down when the NCO value drops to 1.2-1.3mmol / g, and set aside.

[0074] (3) Preparation of solid self-dulling emulsion

[0075] Take 100g of low-viscosity water-based prepolymer, 100g of polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com