Environment-friendly clean mineralized drinking water and sewage disposal method as well as material and equipment thereof

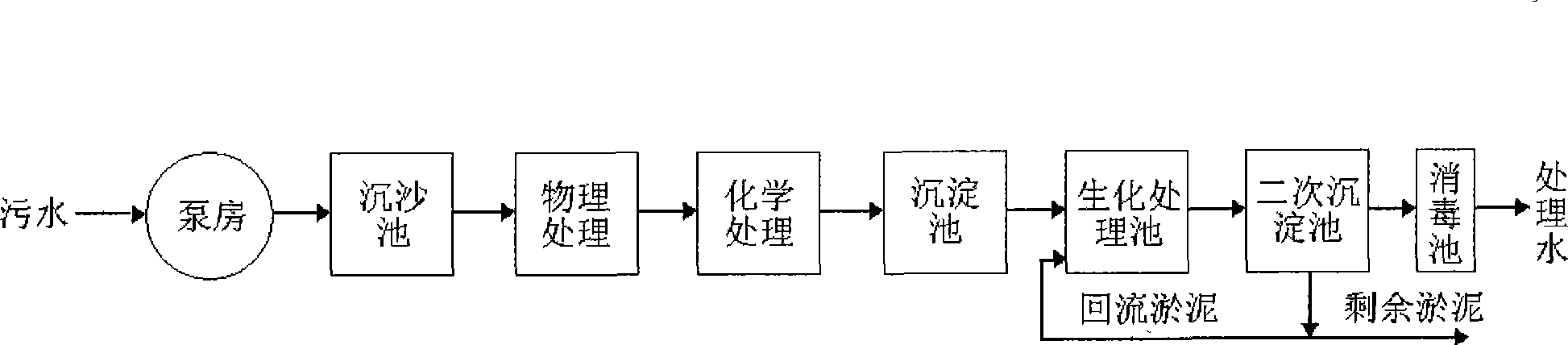

A sewage treatment method and technology of sewage treatment equipment, applied in the field of water treatment, can solve the problems of failing to meet the requirements of human health, unsatisfactory treatment effect, complicated process, etc., and achieve the goal of enhancing human health, huge social benefits and market economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Wooden embodiment technical proportioning pellet scheme:

[0040]

[0041] The processing procedure of this embodiment is:

[0042] The first step: Carry out technical fine processing of non-polluting ores, and conduct technical screening according to the mesh number required by the technical requirements of purified mineralized water: small and medium particles of 5#-10#, 10#-20#.

[0043] The second step: the technical treatment of the pellets, use clean water to remove the dust in the pellets into the washing machine, so as to meet the dust-free requirements of the pellets.

[0044] The third step: Physicochemical technology to treat the pellets, carry out (50%) acid treatment on the pellets in high fluorine and hard water areas, and (10%) alkali solution treatment on the pellets in soft water areas, through ion Exchange to remove unnecessary substances and impurities in the ore.

[0045] Step 4: Technical modification of some pellets, zeolite is smelted at 100-...

Embodiment 2

[0049] This embodiment is suitable for areas with high fluorine content, and the technical proportioning scheme is:

[0050]

[0051] The basic process of this embodiment is the same as that of Embodiment 1.

[0052] combine Figure 4 In this embodiment, the water inlet pipe is arranged at the bottom of the housing, and the water outlet pipe is arranged at the side. At the same time, the back of the housing is provided with a pendant for hanging, which is convenient for hanging.

Embodiment 3

[0054] This embodiment is suitable for high-speed rail and high-speed areas, and the technical ratio scheme is:

[0055]

[0056] The basic process of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com