Potassium persulfate purification device

A technology of potassium persulfate and box, which is applied in the field of potassium persulfate purification equipment, which can solve the problems of long heating and cooling time, cumbersome operation and low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

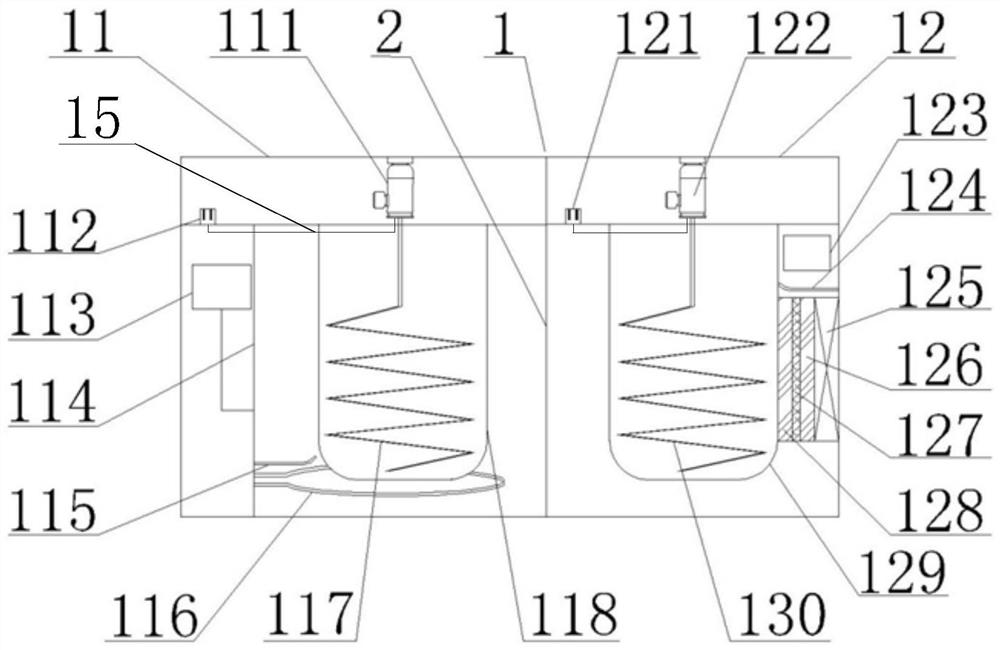

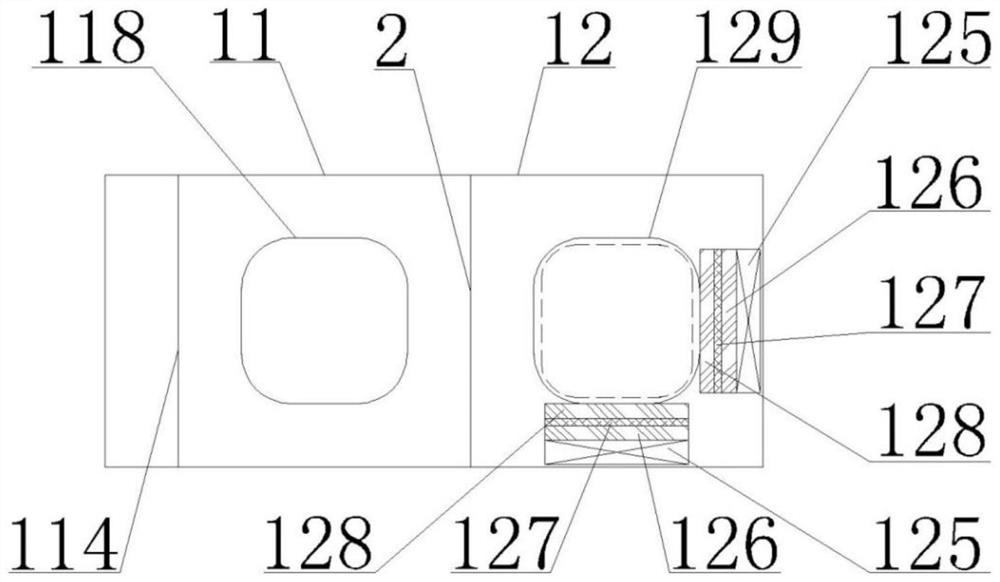

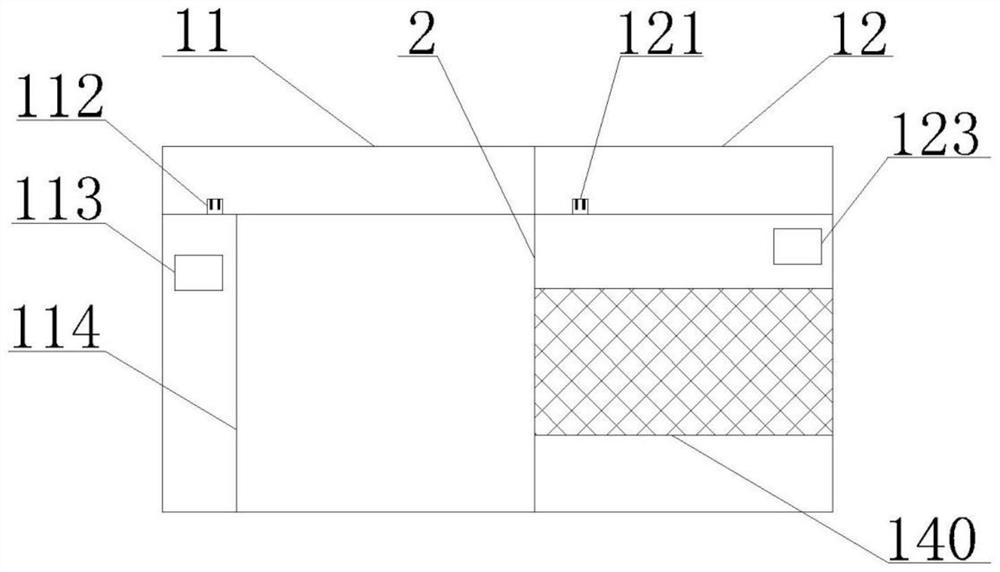

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0028] Such as figure 1 As shown, the device of the present invention includes: a purification box body 1, and an intermediate isolation plate 2 is longitudinally arranged inside the purification box body 1, and the purification box body 1 is divided into a left cavity body 11 and a right cavity body 12; wherein, the left cavity body 11 The first motor 111 is suspended from the top, and the first stirring rod 117 extending to the inside of the first container tank 118 is connected below the first motor 111. An electric heating tube 116 is arranged below the first container tank 118, and the electric heating tube 116 port A first temperature sensor 115 is provided, a first digital display temperature regulator 113 is provided on the left side of the left chamber 11, a first pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com