Method for producing cement additive with industrial residue phosphogypsum

A technology for cement additives and industrial waste residues is applied in the field of production of cement additives, which can solve the problem of high granulation cost, and achieve the effects of reducing storage yard land, low energy consumption, and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

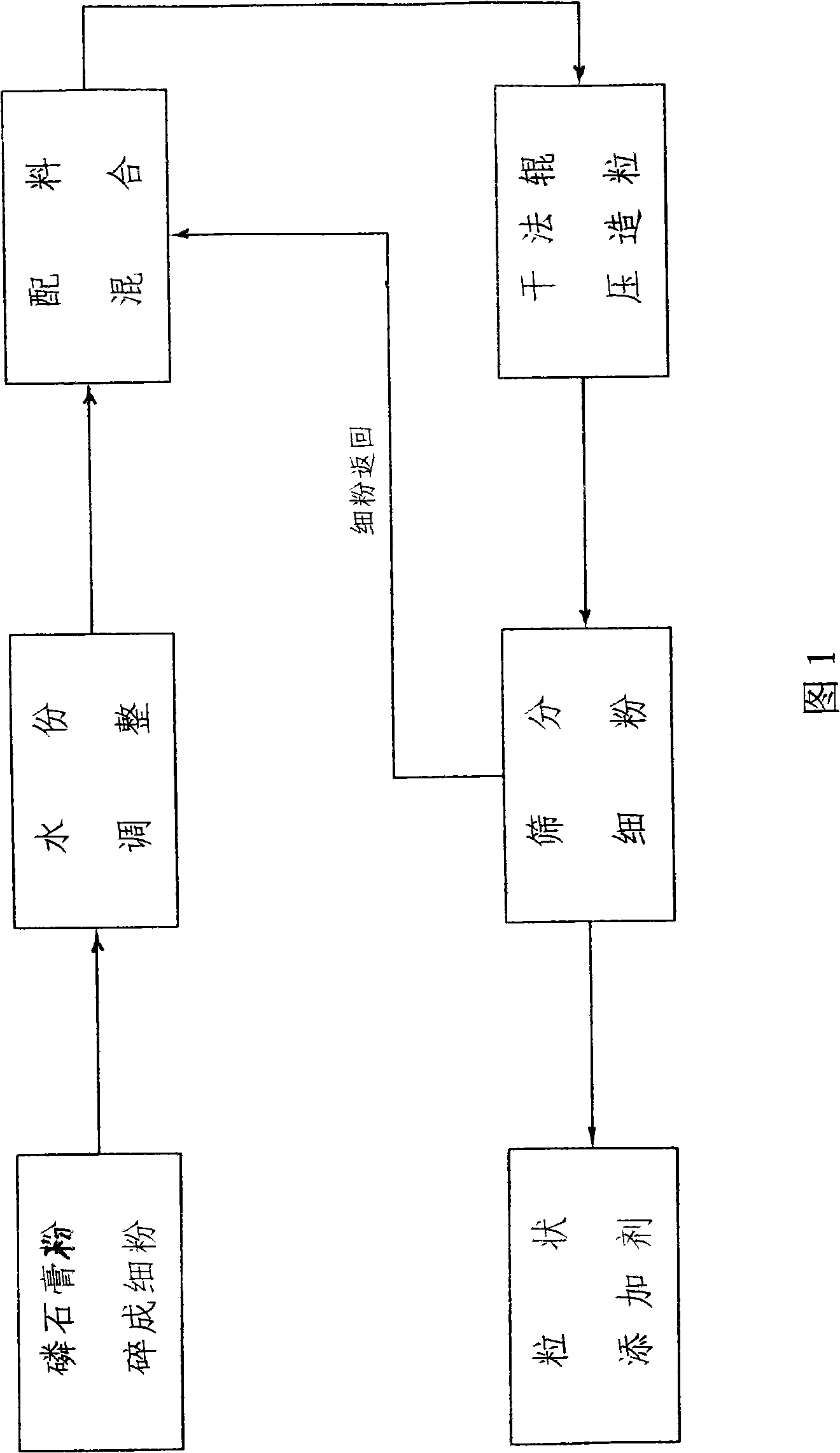

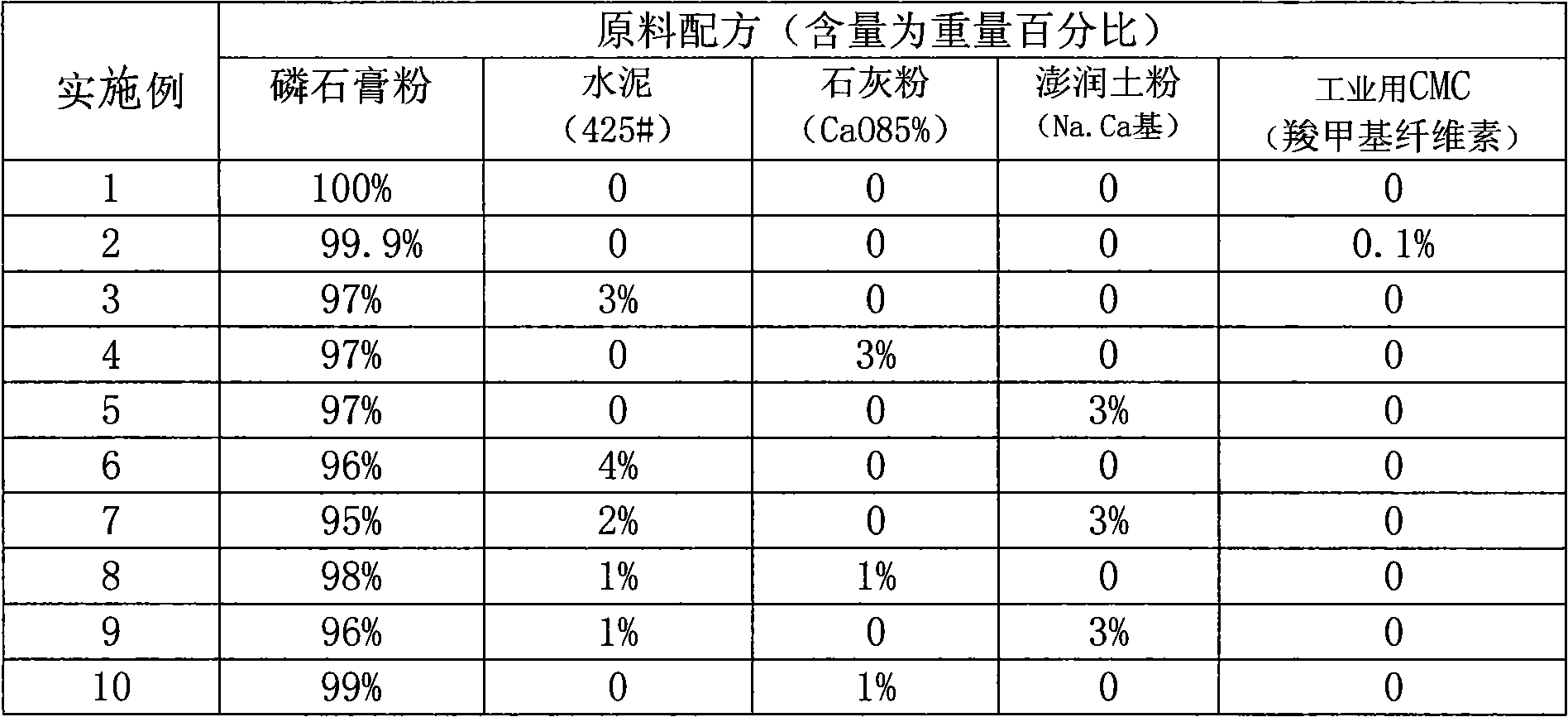

[0023] Select Examples 2-10 for batching, and the production process is shown in Figure 1.

[0024] The phosphogypsum used is the acid-insoluble matter produced by decomposing phosphate rock with sulfuric acid (especially the dihydrate method). A small amount of undecomposed phosphate rock and the main component of dihydrate gypsum account for more than 70% of the phosphogypsum particle size of 80-250 mesh. The original moisture content is 25-30%, and it is naturally air-dried after stacking. The water content is adjusted at 9-11%, and the phosphogypsum powder is mixed with the binder, and then it is dry-pressed by a roller granulator, and the particle size is 10-30mm (other fine powders are returned to the ingredients). Landing is not less than 10mm.

[0025] The granulator used is an existing roller press granulator. The roller surface has a die (also can be a groove stripe), and the die size is large or small, and the shape is different. , The grooved stripes are extruded...

Embodiment 1

[0027] Select embodiment 1, batching has no binding agent.

[0028] The phosphogypsum used is the acid-insoluble matter produced by decomposing phosphate rock with sulfuric acid (especially the dihydrate method). A small amount of undecomposed phosphate rock and the main component of dihydrate gypsum account for more than 70% of the phosphogypsum particle size of 80-250 mesh. The original moisture content is 25-30%, and it is naturally air-dried after stacking. The water content is adjusted at 9-11%, and the phosphogypsum is directly compressed into a particle size of 10-30mm through a roller press granulator. Others are the same as in Example 11.

[0029] The chemical composition of phosphogypsum used in the present invention consists of:

[0030] CaO (calcium oxide) 30.83% SO 3 (sulfur trioxide) 43.48%

[0031] Fe 2 o 3 (Fe2O3) 0.29% AL 2 o 3 (Al2O3) 0.18%

[0032] MgO (magnesium oxide) 1.29% P 2 o 5 (phosphorus pentoxide) 1.29%

[0033] P 2 o 5水溶 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com