Waste heat cyclic utilization type high-efficiency energy-saving drying machine

A waste heat recycling, high-efficiency and energy-saving technology, applied in dryers, drying, heat pumps, etc., can solve problems such as energy consumption and low efficiency of dryers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

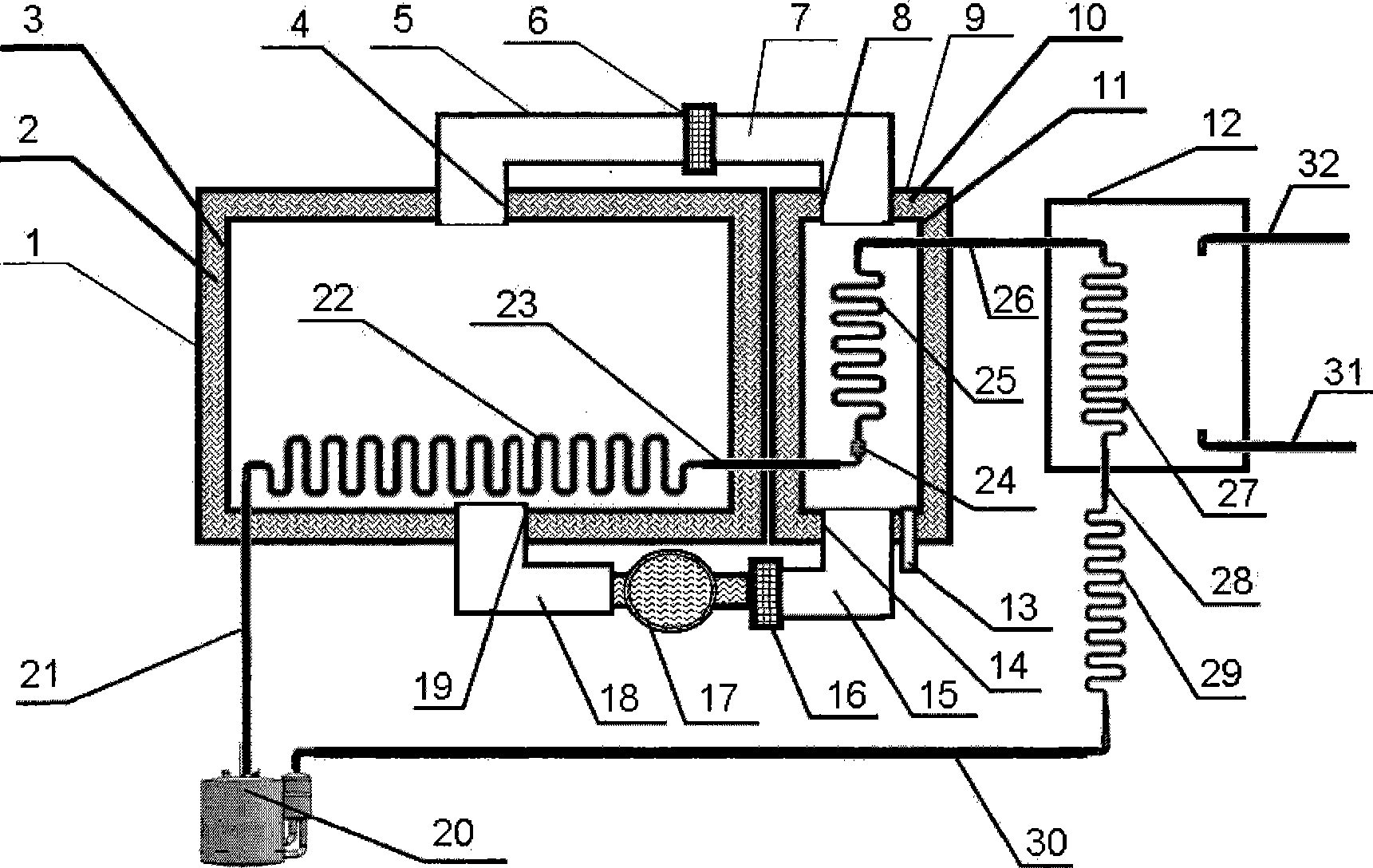

[0023] figure 1 It is a schematic diagram of a waste heat recycling type high-efficiency energy-saving dryer of the present invention.

[0024] like figure 1 As shown, the waste heat recycling type high-efficiency energy-saving dryer of the present invention includes a high-temperature insulation cylinder assembly, a low-temperature insulation cylinder assembly, a multi-source heat pump assembly, a blower device 17, a first filter 6, a drain pipe 13, Temperature sensor (not marked in the figure), humidity sensor (not marked in the figure), frequency converter (not marked in the figure), program controller (not marked in the figure).

[0025] The high-temperature insulation cylinder assembly includes a high-temperature insulation cylinder shell 1, a high-temperature insulation cylinder insulation layer 2, a high-temperature insulation cylinder inner shell 3, a high-temperature insulation cylinder air outlet 4, a high-temperature insulation cylinder air outlet pipe 5, and a hig...

no. 2 approach

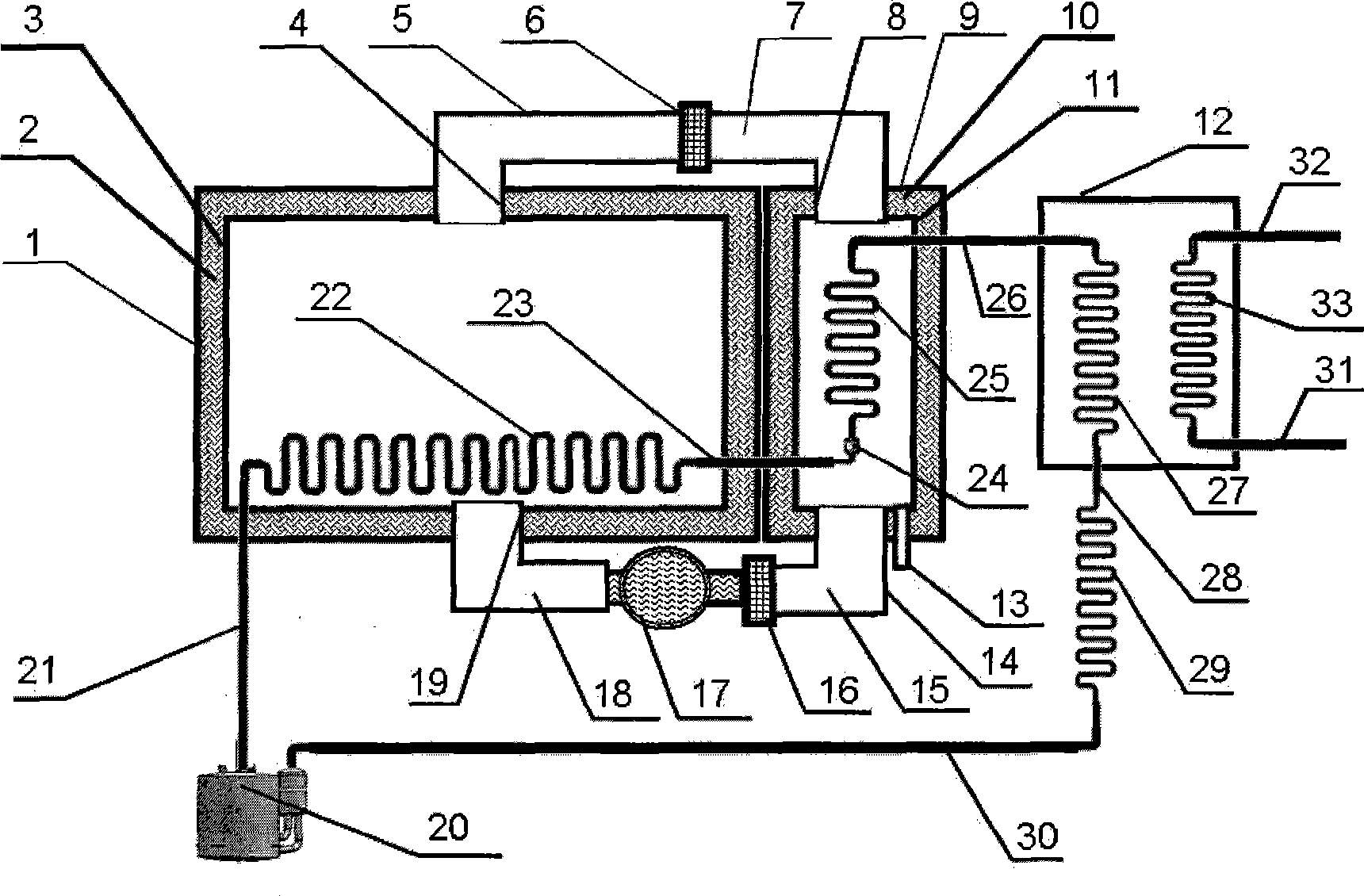

[0037] figure 2 It is a schematic diagram of the second embodiment of the waste heat recycling type high-efficiency energy-saving dryer of the present invention. The second embodiment is basically the same as the first embodiment, except that a heat supplement pipe 31 and a cooling pipe 32 are added to the liquid storage tank 12, so that The heat in the liquid storage tank 12 will be continuously replenished, and the heating effect of the multi-source heat pump assembly can be guaranteed. The fluid in the supplementary heat pipe 31 can be the water of natural temperature, also can be the waste hot water that is useless, also can be the hot water that hot spring discharges, also can be other any fluid that has certain temperature. After cooling, the cooled water is drained through the cooling pipe 32 to maintain a suitable liquid level and temperature in the liquid storage tank 12 .

no. 3 approach

[0039] image 3 It is a schematic diagram of the third embodiment of the waste heat recycling type high-efficiency energy-saving dryer of the present invention. The third embodiment is basically the same as the first embodiment, except that the heat supplementary pipe 31, the cooling pipe 32, and the supplementary heat pipe 31 are added to the liquid storage tank 12. The heat radiation pipe 33, the fluid in the heat supplement pipe 31 and the heat supplement heat dissipation pipe 33 is higher than the temperature of the liquid in the liquid storage tank 12, and the heat supplement heat dissipation pipe 33 will supplement heat to the liquid in the liquid storage tank 12, and then pass through the cooling pipe 32 flow to the designated place, only heat exchange occurs in this process, no substance exchange occurs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com