Coke cleaning system and method for plasma cracking reactor

A pyrolysis reactor and plasma technology, applied in chemical instruments and methods, combustion methods, chemical/physical/physicochemical processes of energy application, etc., can solve problems such as blockage of reactors, hidden safety hazards, shutdown and maintenance, etc., to achieve Keep unblocked, short action time, and ensure the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

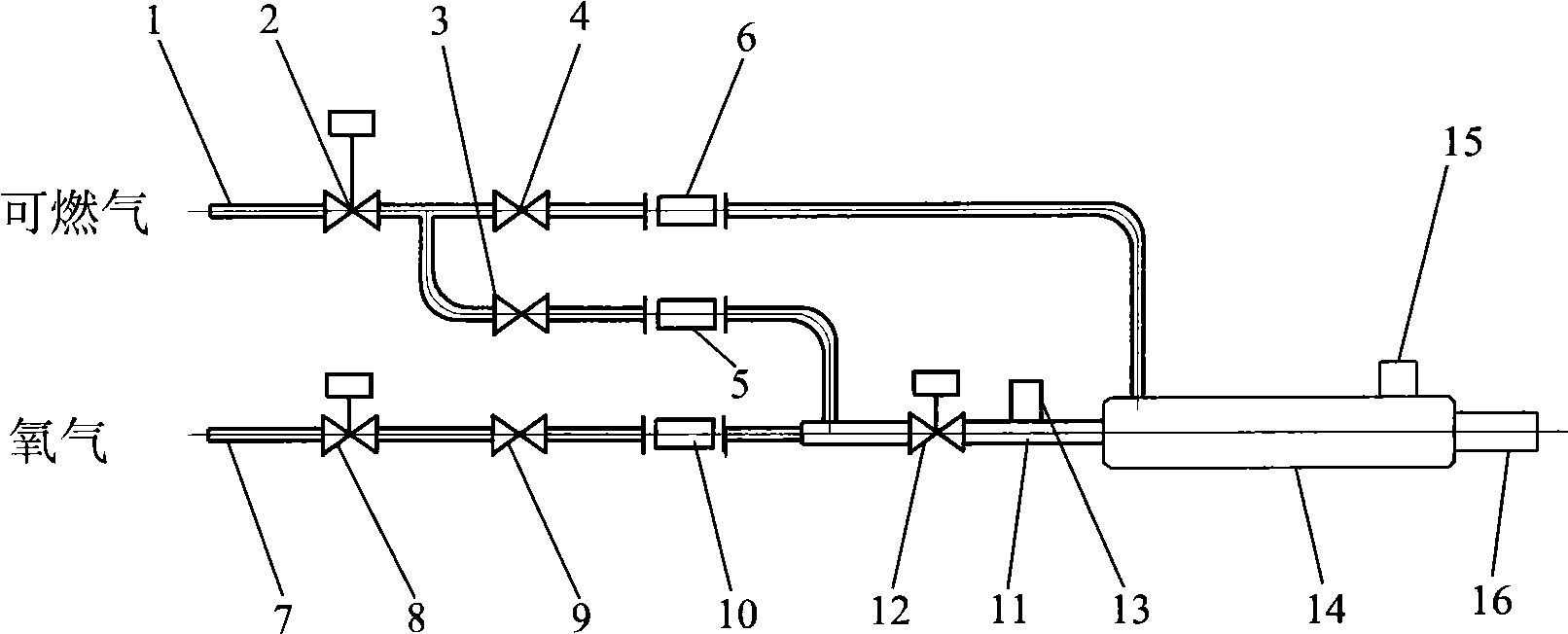

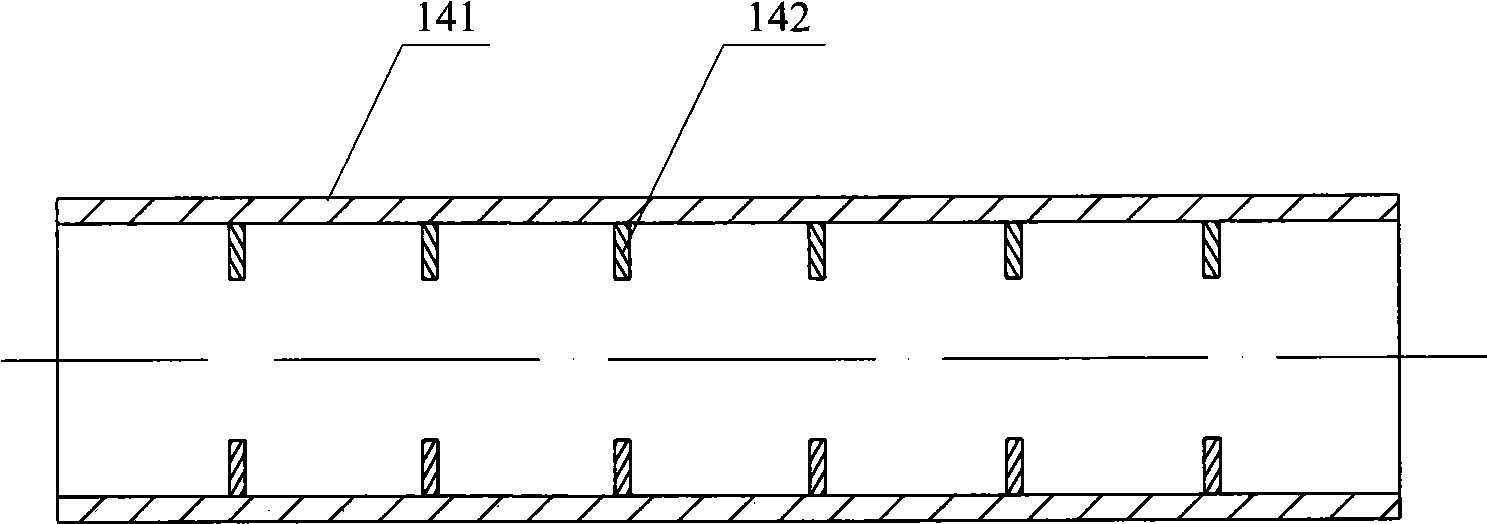

[0020] Such as figure 1 As shown, the embodiment of the present invention provides a coke cleaning system for a plasma cracking reactor, which includes: a combustible gas pipeline 1, a solenoid valve 2, a regulating valve 3, and a flow meter 5 in order to form a combustible gas flow measurement and control pipeline Combustible gas pipeline 1, solenoid valve 2, regulating valve 4, and flowmeter 6 form a secondary combustible gas flow measurement and control pipeline in turn, and oxygen pipeline 7, solenoid valve 8, regulating valve 9, and flowmeter 10 form an oxygen flow measurement and control pipe in turn The pre-combustion chamber 11 is provided with a cut-off valve 12 and an igniter 13, which are directly connected to the fast combustion chamber 14. The cut-off valve 12 is a fast electric ball valve or a pneumatic ball valve, and the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com