Novel connecting mode and component between rough rotator and top rotator in FCC disengager

A connection method and settler technology, used in the petroleum industry, cracking, catalytic cracking, etc., can solve the problem that the rotational kinetic energy of the coarse or fast split exhaust pipe is not utilized, the separation efficiency of the separation system cannot be improved, and the catalyst separation function is not available. and other problems, to achieve the effect of easy manufacturing and installation, small device changes, and optimization of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

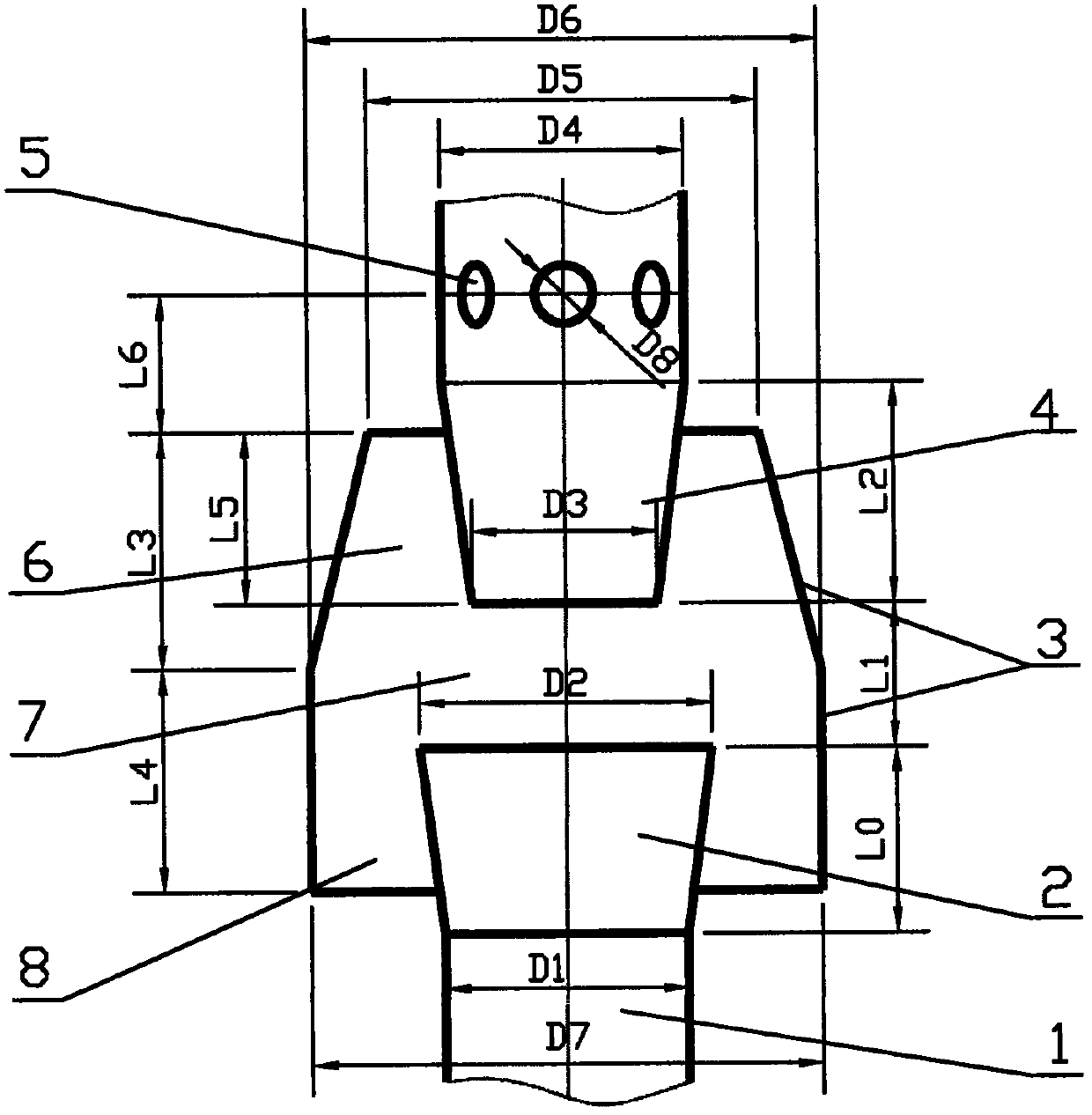

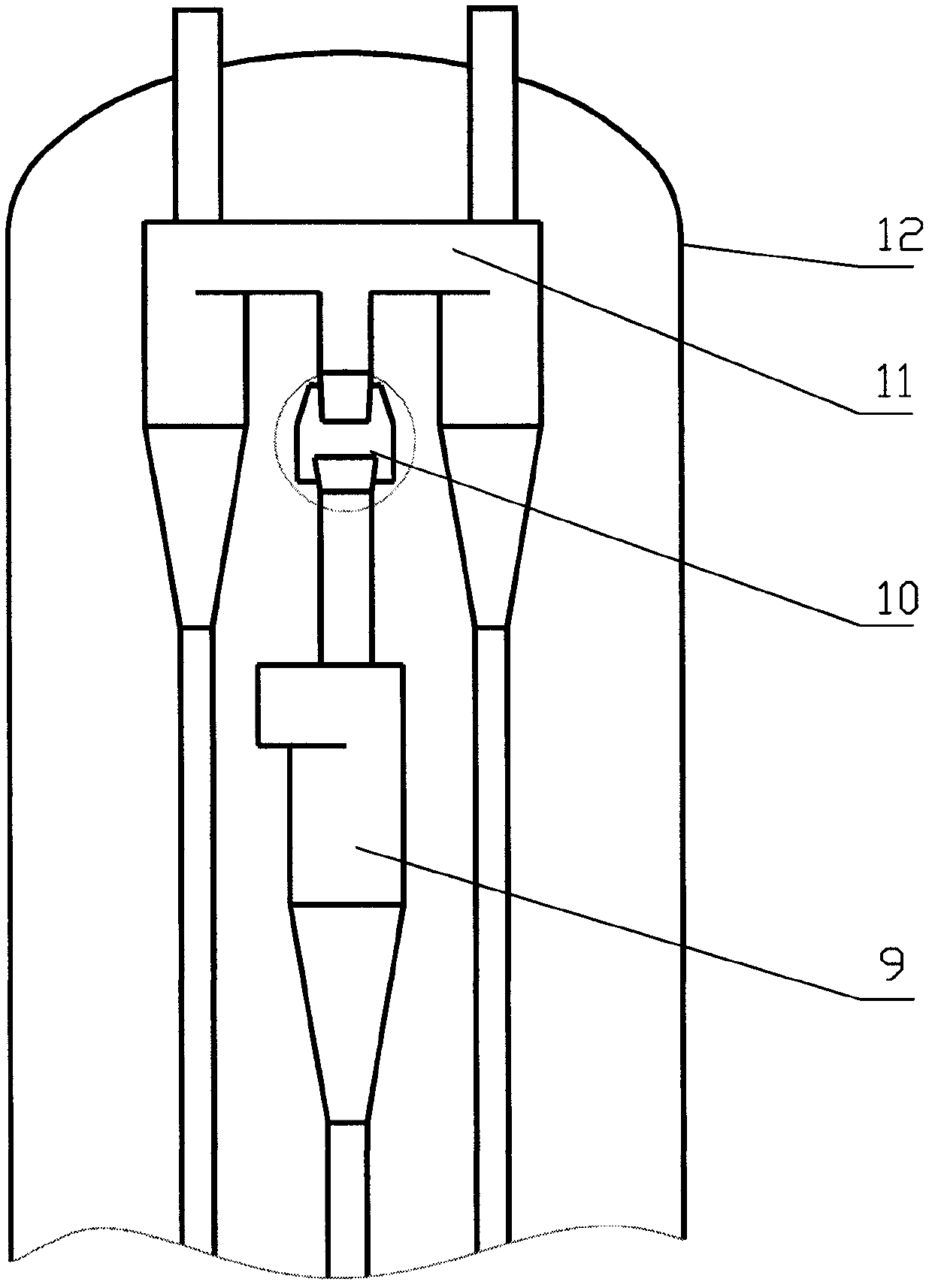

[0022] refer to figure 1 and figure 2 , the new connection method and components between the rough rotation and the top rotation in the FCC settler proposed by the present invention are located inside the settler shell 12, consisting of a rotating incoming flow pipe 1, an expansion section 2, a restrictor cover 3, and an exhaust pipe 4 , the stripping steam inlet 5, the top buffer separation space 6, the annular connection separation space 7 and the dust outlet and the stripping steam inlet 8.

[0023] refer to figure 1 , the rotating incoming flow pipe 1 is coaxially connected to the exhaust pipe of the cyclone separator (or quick separation) or any other pipe with rotating dust-laden airflow, or it is the exhaust pipe of the cyclone separator or any other pipe with rotating dust-laden airflow. The dust airflow pipe has a diameter of D1 and a length of 0.5D1 to 200D1.

[0024] refer to figure 1 , the small-diameter end of the gradually expanding section 2 is coaxially co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com