Biomass combustion device for docking boilers, heat exchangers, heating systems

A heat exchanger and heat supply system technology, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve problems such as inability to work continuously and stably, low combustion efficiency, low fire temperature, easy to block pipes, etc., and achieve reduction The number of times the furnace is shut down to remove slag, the effect of reducing carbon deposits and eliminating coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

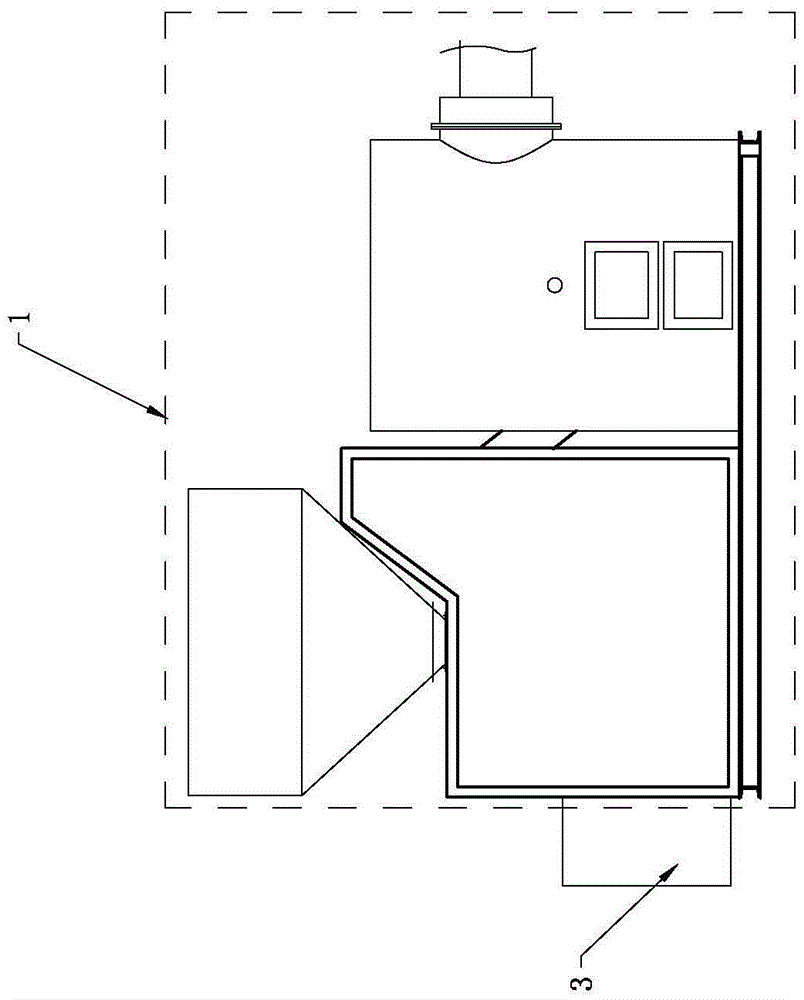

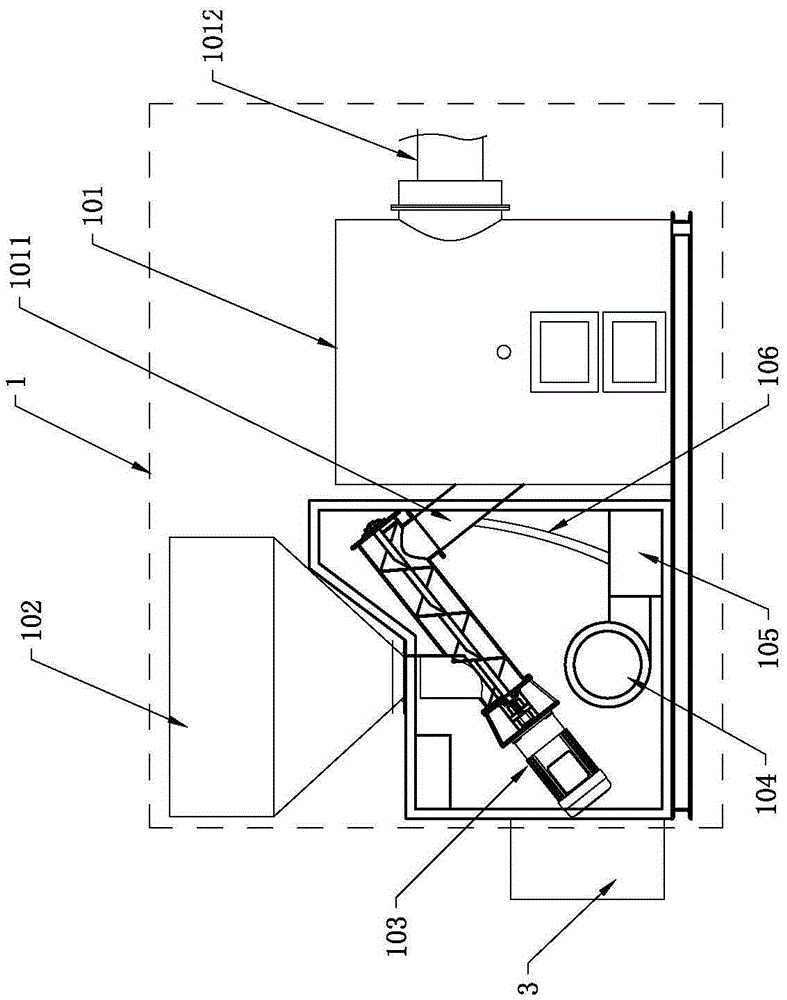

[0044] Biomass combustion devices for docking boilers, heat exchangers, heating systems, such as figure 1As shown, it includes a burner body 1 , a carbonizer for generating the fuel required for combustion of the burner body 1 , and a steam generator 3 . The steam output pipe 301 of the steam generator 3 communicates with the furnace 101 of the burner body 1 . The carbonization machine is equipped with a cracking area and an outlet for discharging cracked gas and tar. The biomass raw material is initially cracked by the carbonization machine and tar is precipitated to obtain biomass fuel. The biomass fuel is sent to the furnace 101 of the burner body 1 for combustion. After the material fuel is burned, the steam generator 3 injects steam into the furnace 101 of the burner body 1 through the steam output pipe 301 . In this embodiment, the burner body 1 is a traditional biomass combustion device for connecting boilers, heat exchangers, and heating systems, and the carbonizer and...

Embodiment 2

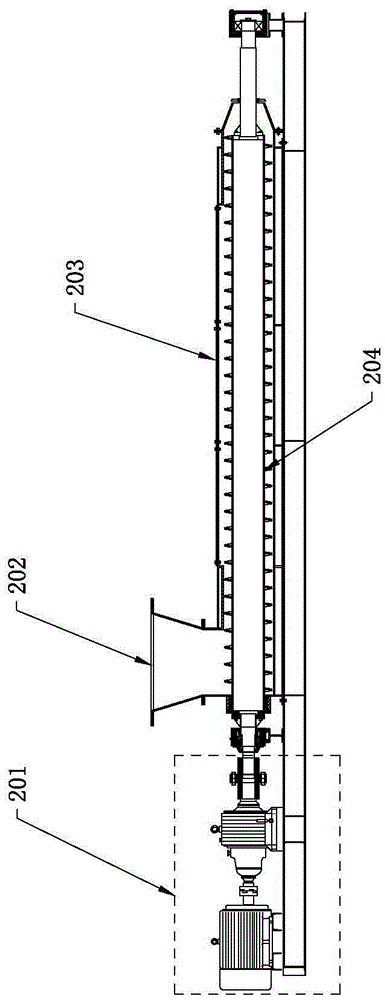

[0049] like figure 2 As mentioned above, the difference between the biomass combustion device used for docking boilers, heat exchangers, and heating systems in this embodiment and that in Embodiment 1 is that the carbonization machine in this embodiment is independently developed, and the carbonization machine includes a cracking device , the cracking device comprises a driving device 201, a screw rod 204 and a barrel 203, the driving device 201 is drivingly connected with the screw rod 204, the screw rod 204 is rotatably worn inside the barrel 203, and the inner wall of the barrel 203 is provided with a heating layer and an insulating layer , the insulation layer is arranged between the inner wall of the barrel 203 and the heating layer, a cracking zone is formed between the screw rod 204 and the heating layer, and the cracking zone discharges cracked gas and tar through the discharge port of the cracking device. The barrel 203 of the cracking device in this embodiment is al...

Embodiment 3

[0053] The biomass combustion device used for docking boilers, heat exchangers, and heating systems of this embodiment is based on Embodiment 2. The carbonization machine of this embodiment also includes a feeding device. The feeding device includes a feeding hopper, a second Two drive devices, a second barrel and a second screw, the second drive is connected to one end of the second screw, the other end of the second screw is rotatably inserted inside the second barrel, the feed hopper is connected to the second screw The feed end of two barrels communicates, and the discharge end of the second barrel communicates with the cracking zone of cracking device; Below the screw 204 of the device. In this embodiment, since the feeding device is provided with a feeding hopper, the barrel 203 of the cracking device is no longer set into the hopper 202 .

[0054] In order to ensure that the pyrolysis device is in an anoxic and airtight state, the feeding device of this embodiment also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com