Micropore ligno-cellulose ultramicro powder, as well as preparation method and application thereof

A technology of lignocellulose and ultrafine powder, applied in lignin coating, fiber treatment, coating and other directions, can solve the problems of poor reactivity, microporous damage, damage to microporous structure, etc., to improve the aging resistance and improve the aging resistance. performance, the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

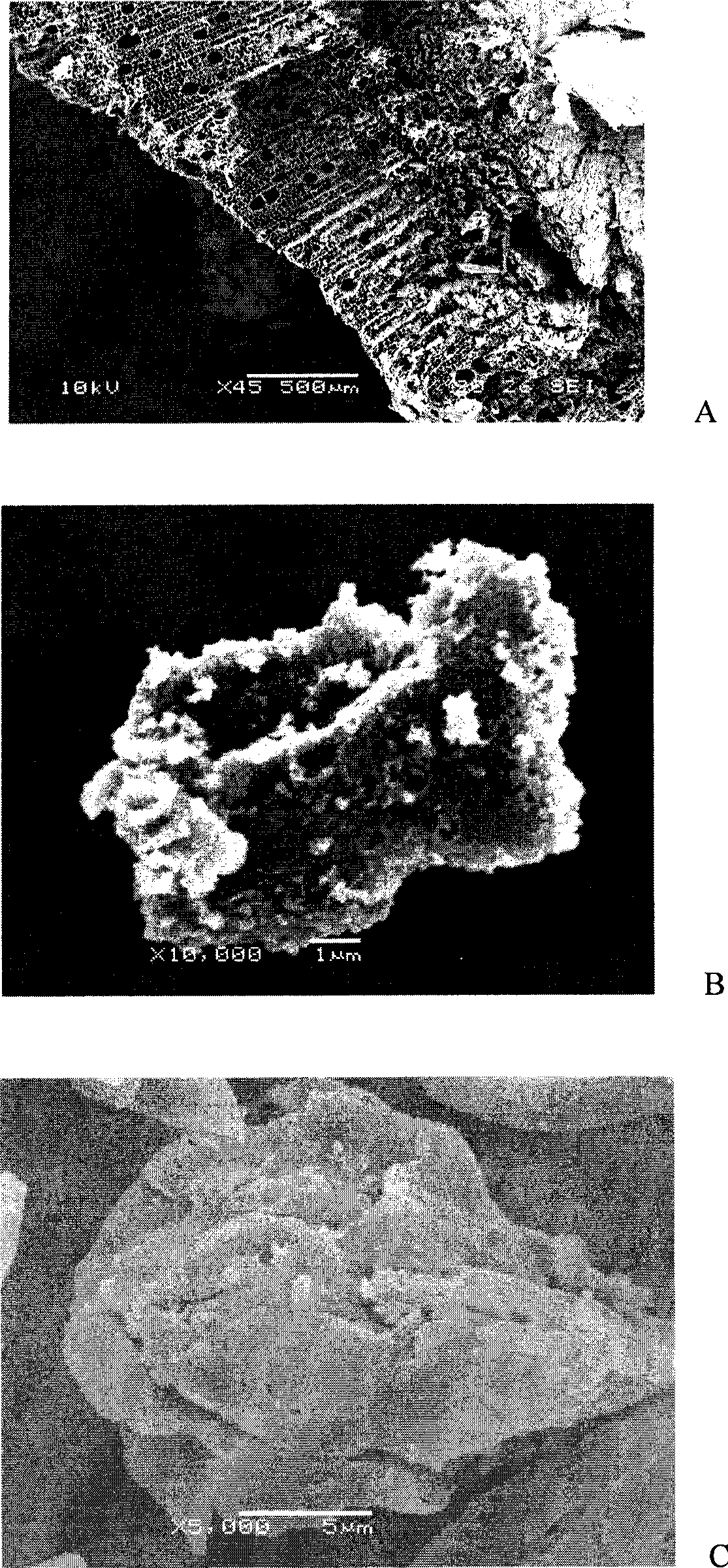

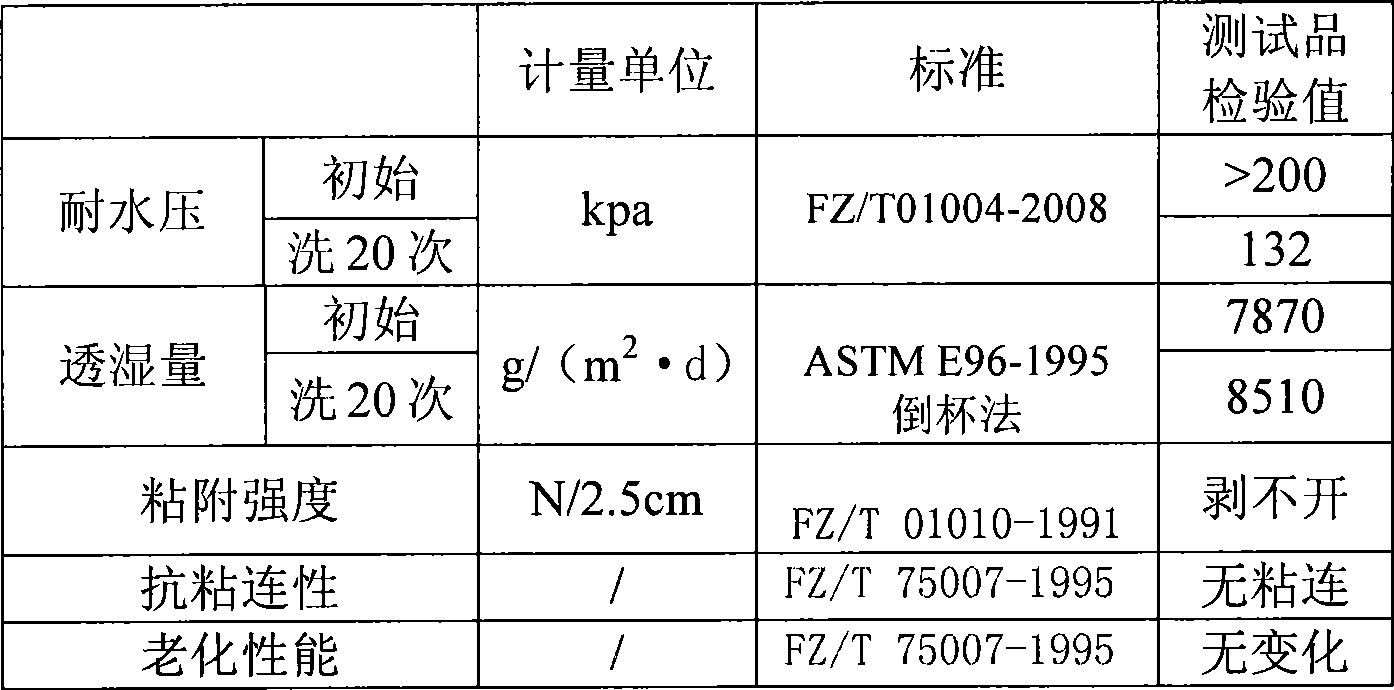

Image

Examples

preparation example Construction

[0038] Preparation of the waterproof coating agent: add a certain amount (20wt%) of the superfine powder additive of the present invention in the normal polyurethane coating agent production process, and carry out the synthesis reaction according to the conventional process to obtain the waterproof coating agent.

[0039]Preparation of waterproof coated fabric: After the fabric is waterproofed and calendered, the waterproof coating agent is coated on the base fabric to make a coated fabric with waterproof and moisture permeability as a test product.

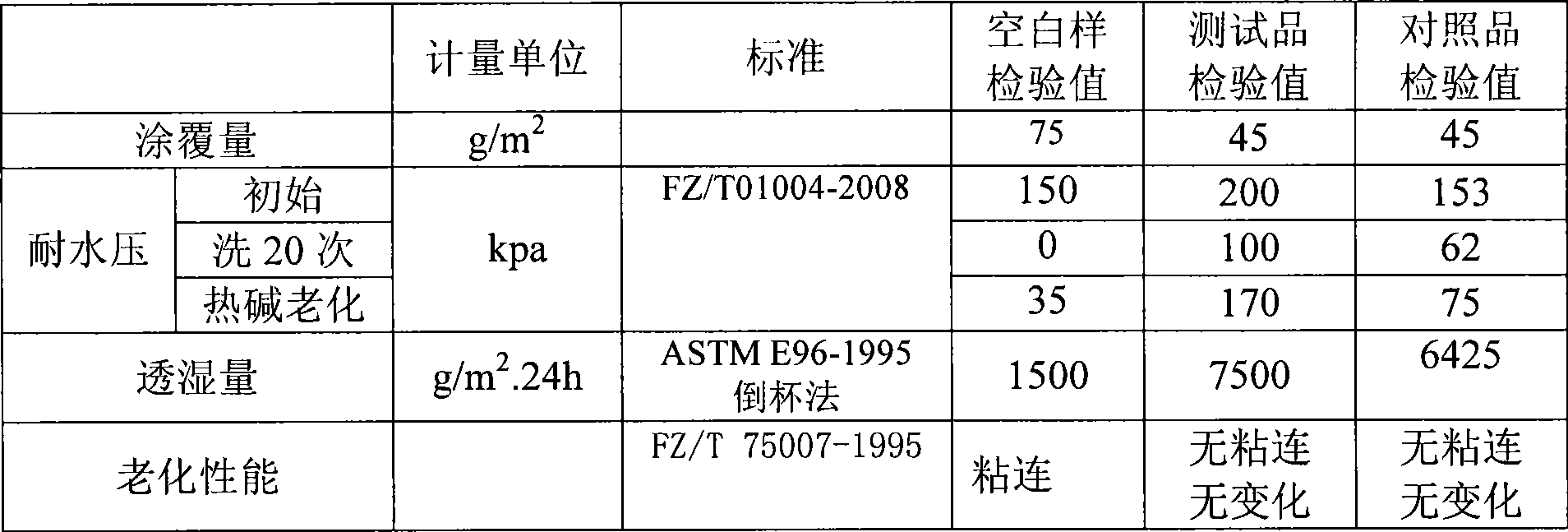

[0040] The related performance test of the coated fabric is carried out, and the test results are shown in Table 1.

[0041] Table 1:

[0042]

[0043] 4. Comparative experiment: Coating the same base cloth with ordinary PU waterproof and moisture-permeable coating glue to make a blank reference product; coating the same base cloth with ordinary PU glue with 20wt% ordinary fine powder (200 mesh) Covered to make a comparative ...

Embodiment 1

[0056] Embodiment 1: the preparation of superfine powder of hemp rod core

[0057] 1) Raw material crushing: the hemp rod core is crushed into a coarse powder of about 20 meshes with a jaw crusher.

[0058] 2) Pretreatment: Take 1kg of coarse powder and put it into a 50L stainless steel reaction kettle, add 100g of caustic soda, 10g of sodium sulfide and 5L of water, and stir for 6 hours at a temperature of 80°C; after filtering, centrifugally dry the precipitated powder and put it in a hot air furnace at 140°C drying to a moisture content of 1 wt%; natural cooling to obtain modified coarse powder.

[0059] 3) Refining treatment: Put the coarse powder into a Raymond mill to grind for 2 hours to a fine powder of 200 mesh, and control the particle size of the powder through wind screening.

[0060] 4) Activation treatment: Take 1kg of 200 mesh fine powder and put it into a 50L reactor, add 10kg of caustic soda solution with a concentration of 5g / l, stir at 50°C for 4 hours for ...

Embodiment 2

[0064] Embodiment 2: the preparation of superfine powder of bleached hemp rod core

[0065] The same operation as in Example 1, adding a bleaching process in step 2). The specific step 2) is: take 1 kg of coarse powder and put it into a 50 L stainless steel reaction kettle, add 100 g of caustic soda, 10 g of sodium sulfide, and 5 L of water, and stir for 6 hours at a temperature of 80 ° C; drain and rinse after filtering, and add 500 mL of hydrogen peroxide to the precipitate, Stir at 80-100°C for 3-30 hours; then, add an appropriate amount of acetic acid to neutralize, filter and wash with water until the precipitate reaches a pH of 5-8; dry the precipitated powder by centrifugation, and dry it in a hot air oven at 140°C until it reaches moisture Content 1wt%; natural cooling to obtain modified coarse powder.

[0066] Through this operation, bleached coarse powder can be obtained. The superfine powder obtained after the follow-up treatment of the coarse powder has a finenes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com