Sol-coated membrane and preparation method and use thereof

A diaphragm and sol technology, applied in the field of electrochemistry, can solve problems such as combustion, poor consistency, and diaphragm shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] In one embodiment of the present invention, the preparation method of described sol coating liquid comprises the following steps:

[0060] (i) take inorganic sol particle and the water as dispersion medium in proportion;

[0061] (ii) Glue making: use a mixer or mixer to stir for more than 1 hour to produce a clear glue;

[0062] (iii) Addition of binder: Add the water-based binder into the clarified glue solution, and use a mixer or mixer to stir for more than 1 hour to form a stable sol solution;

[0063] (iv) Vacuum defoaming: adjust the mixer to slow stirring, vacuumize for 30min, and carry out defoaming;

[0064] (v) Filtration: vacuum filter the above-mentioned degassed sol solution to obtain the sol coating solution required by the present invention.

[0065] In order to improve the surface tension of the obtained sol coating solution, increase the uniformity of coating and coating, the step of adding surfactant can be added between the above-mentioned (iii) st...

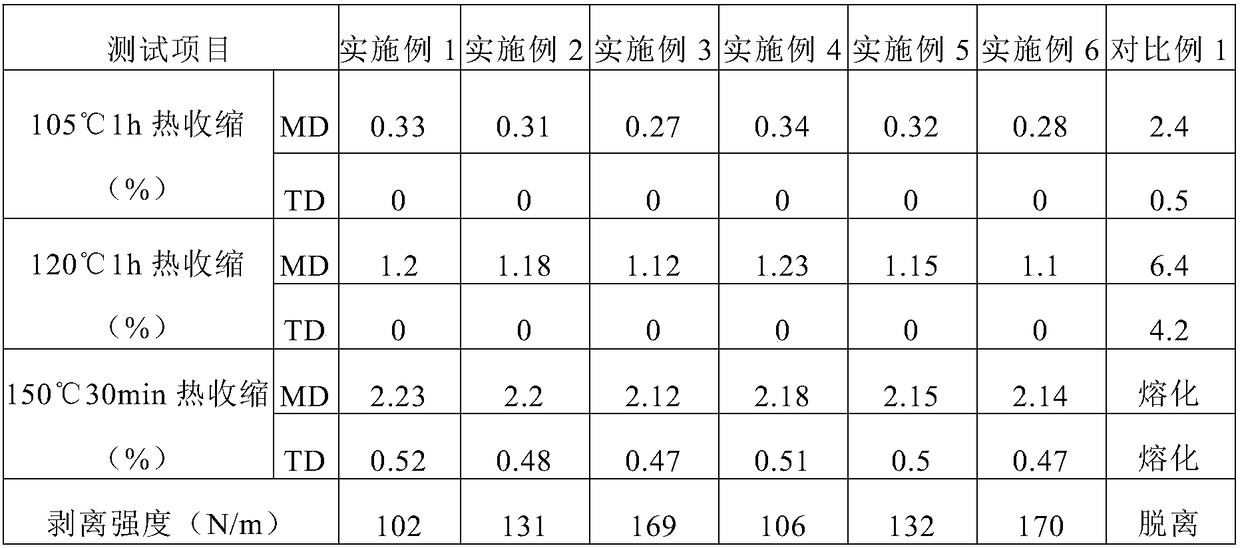

Embodiment 1-6

[0108] Preparation of sol-coated separators

[0109] 1) Select the SV10 series PE microporous base film produced by Shanghai Enjie Company, with a thickness of 10 μm;

[0110] 2) The PE microporous base film is passed through the MCD type coating machine (purchased from Fuji Machinery Industry Co., Ltd.), and the sol coating solution described in Table 1 and Table 2 is coated on the PE microporous film through gravure printing at the same time After being baked in an oven, a PE microporous membrane covered with an inorganic sol coating can be prepared, and the thickness of the coating is 2 μm.

[0111] Table 1

[0112]

[0113] Table 2

[0114]

[0115] Note: The proportion of each material is calculated as solid

Embodiment 7-10 and comparative example 2

[0124] Preparation of lithium-ion batteries

[0125] The lithium-ion battery consists of a positive electrode system, a negative electrode system, and an electrolyte system. The positive electrode uses lithium manganese oxide, the negative electrode uses graphite, and the electrolyte uses an EC / EMC system. The concentration of lithium salt (LiPF6) is 1mol / L. Preparation process: the positive electrode is composed of lithium manganese oxide, the negative electrode is composed of graphite, carboxymethyl cellulose (CMC), and styrene-butadiene rubber emulsion in a weight ratio of 100:2:3, and the negative electrode uses water as the solvent to make negative electrode slurry. Diaphragms shown in Table 3. The cut pole pieces are crimped and packed with aluminum-plastic film, organic electrolyte is added in the state of nitrogen, the battery is evacuated and sealed, and then the battery is aged at room temperature for 3 hours, and it is formed into a lithium-ion battery.

[0126] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com