Chitosan-based gel material with double-layer-anisotropic structure as well as preparation method and application of chitosan-based gel material

An anisotropic, gel material technology, applied in chemical instruments and methods, general water supply conservation, water/sludge/sewage treatment, etc., can solve problems such as poor biodegradability, low light-to-heat conversion efficiency, and high production costs , to achieve excellent thermal insulation performance, improve light-to-heat conversion efficiency, and improve heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

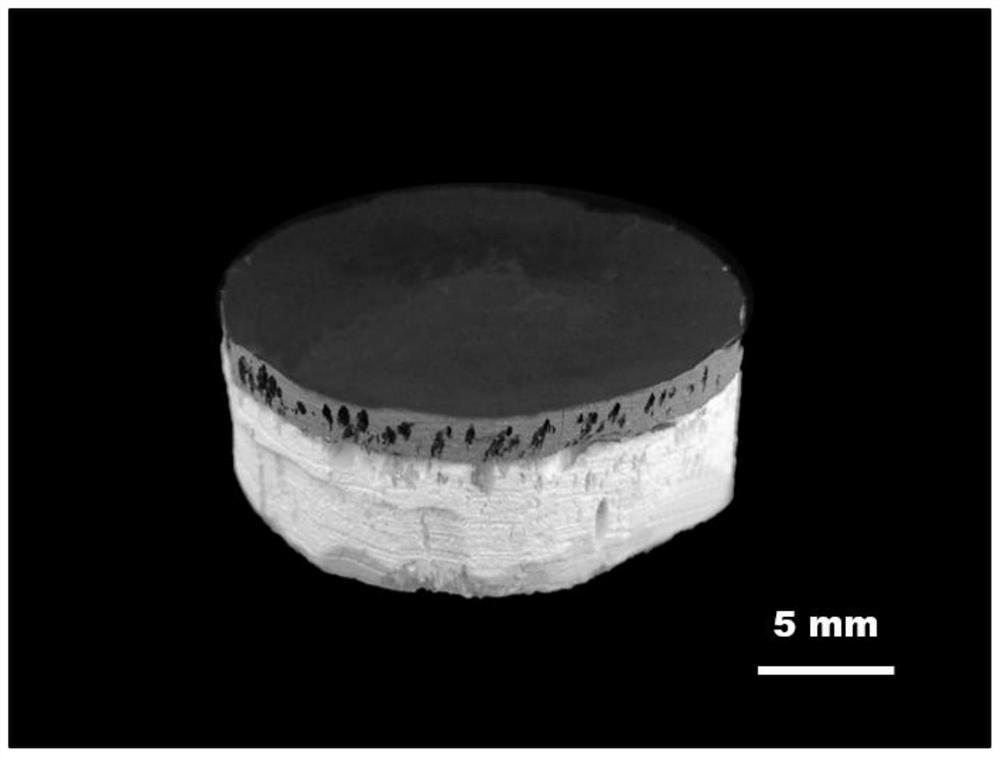

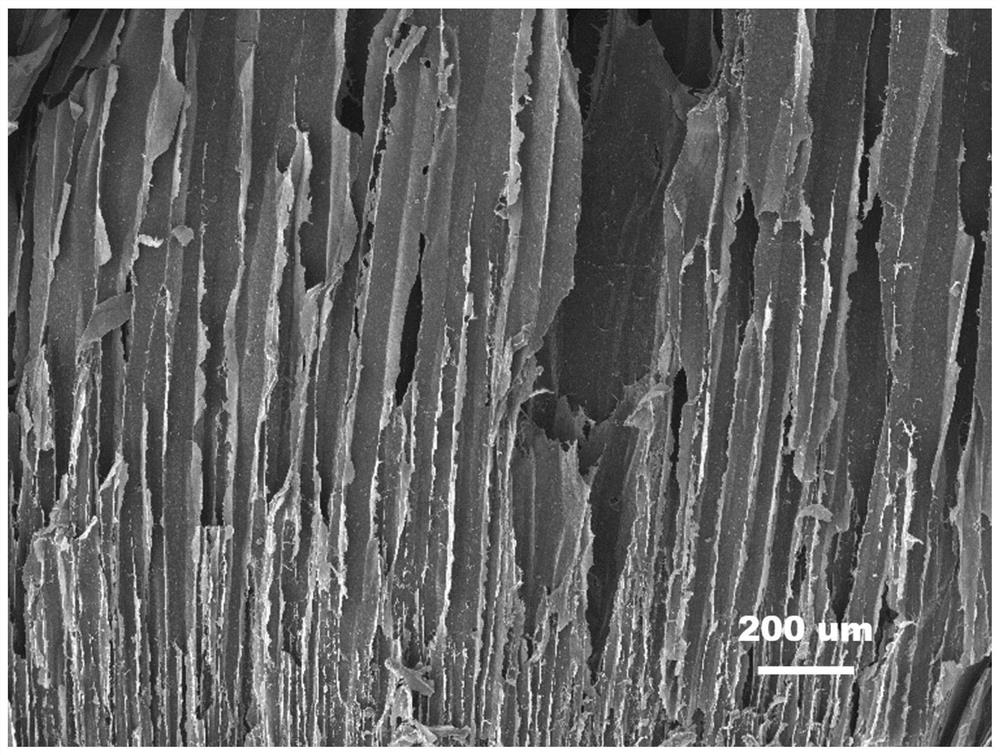

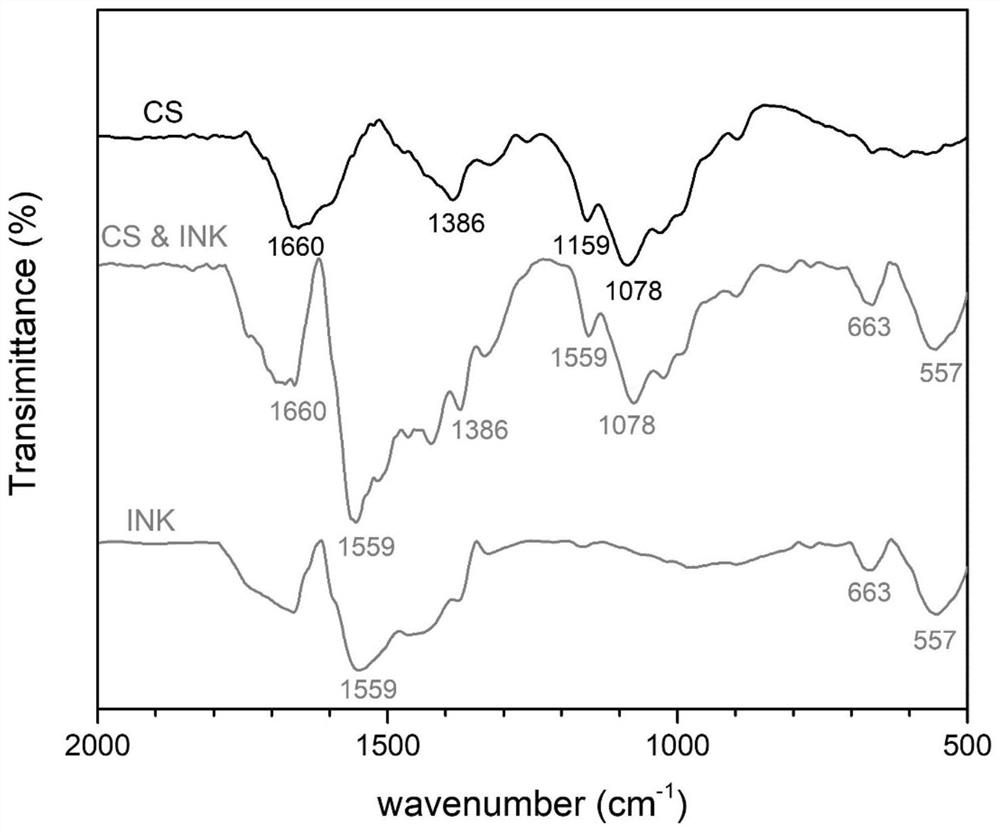

[0035] Such as Figure 6 As shown, the invention discloses a preparation method of a bilayer-anisotropic structure chitosan-based gel material, which produces a chemically cross-linked network through acid-base neutralization and gelation. Specifically include the following steps:

[0036] (1) configure chitosan solution

[0037] Prepare a chitosan solution with a mass fraction of 1% to 5%: weigh chitosan with a mass of 1-5g, disperse it in deionized water, add 2g of acid solution with pH=3 to it, and stir until the chitosan Dissolve completely to obtain chitosan solution.

[0038] (2) Configure black chitosan-ink mixture

[0039] Prepare a chitosan-ink mixture with an ink content of 1% to 10%: weigh 1-5g of chitosan, disperse it in deionized water, add 2g of an acid solution with pH=3 to it, and stir until the shell After the polysaccharide is completely dissolved, add 1-10g of ink, and stir until the black color is evenly dispersed to obtain a black chitosan-ink mixture....

Embodiment 1

[0054] (1) configure the black chitosan-ink ink mixture of ink content 1%

[0055] Weigh 1g of chitosan, disperse it in 96g of deionized water, add 2g of acetic acid solution with pH=3 to it, stir until the chitosan is completely dissolved, add 1g of ink, stir until the black color is uniformly dispersed, and the shell is obtained. Polysaccharide-ink mixture.

[0056] (2) Preparation of black chitosan hydrogel

[0057] A, the chitosan-ink mixed solution obtained by step (1) is centrifugally defoamed at a high speed, and then transferred to a single-opening mould;

[0058] B, the mold that mixed solution is housed is placed in sodium hydroxide coagulation bath and completes gelation, obtains black chitosan hydrogel;

[0059] c, using deionized water to wash the black chitosan hydrogel until the pH is neutral.

[0060] (3) Preparation of double-layer two-color chitosan hydrogel

[0061] a, configuration mass fraction 1% chitosan solution

[0062] Configuration mass fraction...

Embodiment 2

[0070] (1) configure the black chitosan-ink ink mixture of ink content 10%

[0071] Weigh 1g of chitosan, disperse it in 87g of deionized water, add 2g of hydrochloric acid solution with pH=3 to it, stir until the chitosan is completely dissolved, add 10g of ink, stir until the black color is uniformly dispersed, and the shell is obtained. Polysaccharide-ink mixture.

[0072] (2) Preparation of black chitosan hydrogel

[0073] A, the chitosan-ink mixed solution obtained by step (1) is centrifugally defoamed at a high speed, and then transferred to a single-opening mould;

[0074] B, the mold that mixed solution is housed is placed in potassium hydroxide coagulation bath and finishes gelation, obtains black chitosan hydrogel;

[0075] c, using deionized water to wash the black chitosan hydrogel until the pH is neutral.

[0076] (3) Preparation of double-layer two-color chitosan hydrogel

[0077] a, configuration mass fraction 1% chitosan solution

[0078] Configuration mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com