Preparation method for highly water-pressure-resistant, highly air permeable and highly wet permeable garment film

A water pressure-resistant and highly breathable technology, which is used in outdoor waterproofing, footwear, military uniforms, breathable and moisture-permeable clothing, and can solve problems such as poor breathability and moisture-permeability, and low water pressure resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

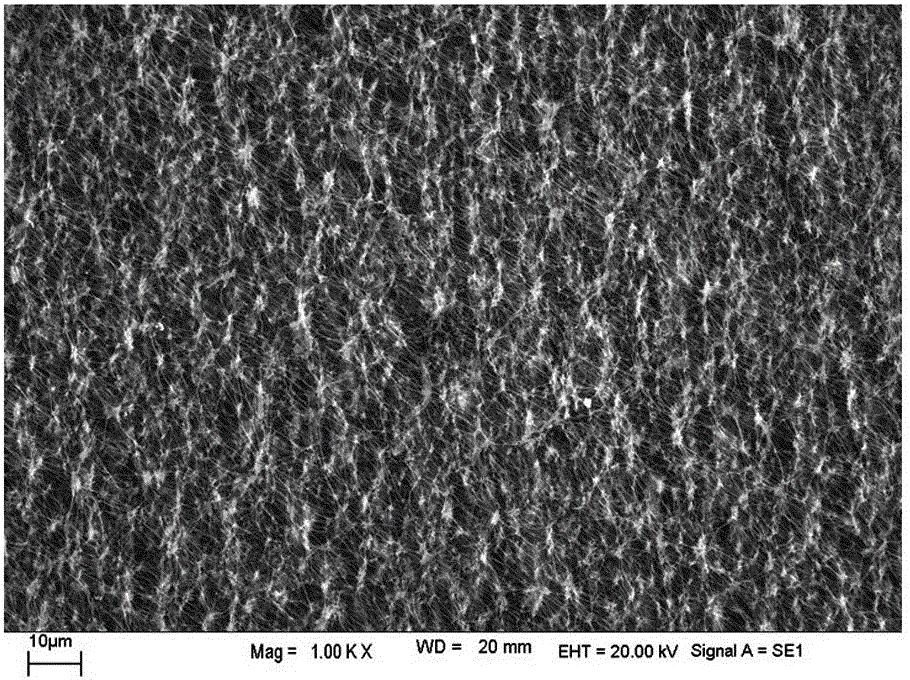

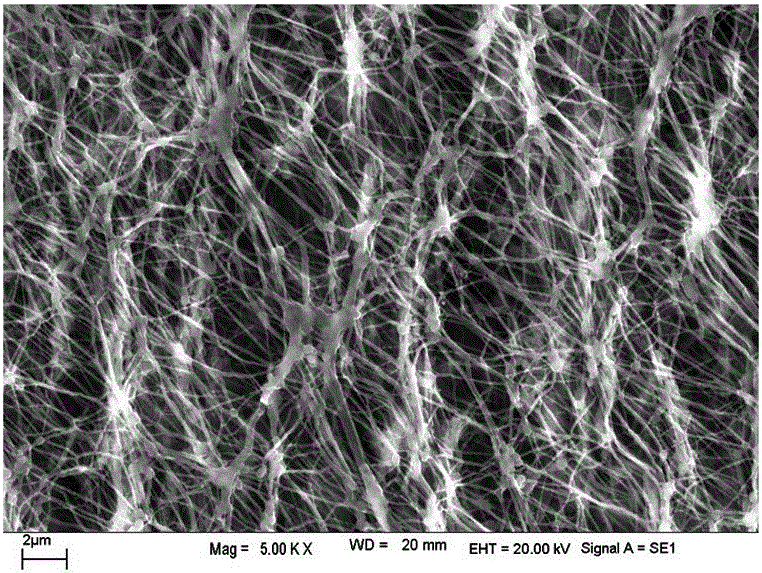

Image

Examples

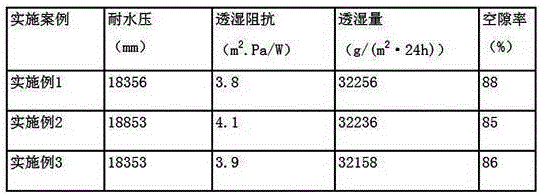

Embodiment 1

[0031] A method for preparing a garment film with high water pressure resistance, high air permeability and high moisture permeability, comprising the steps of:

[0032] 1. Mix the dispersed polytetrafluoroethylene resin powder, solvent and surfactant according to a certain mass ratio (100:25:0.25). Tetrafluoroethylene resin powder, then mix evenly;

[0033] (1) The particle size of dispersed polytetrafluoroethylene resin powder is 0.1-0.2 μm, the molecular weight is above 8 million, and the crystallinity is ≥98%;

[0034] (2) The solvent is a mixture of isoparaffins and normal alkanes, wherein the content of isoparaffins is 90wt%, the content of normal alkanes is 10wt%, the isoparaffins are isooctane-like, and the normal alkanes are n-pentane;

[0035] (3) The surfactant is toluene;

[0036] 2. Stirring: Stir the mixture obtained in step 1 at a constant temperature of 40°C for 0.5 hours at a constant speed to make it fully mixed;

[0037] 3. Maturation: Put the mixed mater...

Embodiment 2

[0048] A method for preparing a garment film with high water pressure resistance, high air permeability and high moisture permeability, comprising the steps of:

[0049] 1. Mix the dispersed PTFE resin powder, solvent, and surfactant in a certain mass ratio (100:26:0.08). The order of addition is: first add the surfactant to the PTFE, and then mix well Add to the solvent and mix well;

[0050] (1) The particle size of dispersed polytetrafluoroethylene resin powder is 0.1-0.2 μm, the molecular weight is above 8 million, and the crystallinity is ≥98%;

[0051] (2) The solvent is a mixture of isoparaffin and normal alkane, wherein the content of isoparaffin is 98%, the content of normal alkane is 2%, the isohexadecane is isohexadecane, and n-octane is the normal alkane;

[0052] (3) The surfactant is ethylene glycol;

[0053] 2. Stirring: Stir the mixture in step 1 at a constant temperature of 38°C for 0.5 hours at a constant speed to make it fully mixed;

[0054] 3. Maturatio...

Embodiment 3

[0065] A method for preparing a garment film with high water pressure resistance, high air permeability and high moisture permeability, comprising the steps of:

[0066] 1. Mix the dispersed polytetrafluoroethylene resin powder, solvent and surfactant according to a certain mass ratio (100:30:0.15). The order of addition is: first add the surfactant to the polytetrafluoroethylene, after mixing Add to the solvent and mix well;

[0067] (1) The particle size of dispersed polytetrafluoroethylene resin powder is 0.1-0.2 μm, the molecular weight is 8 million-10 million, and the crystallinity is ≥98%.

[0068] (2) The solvent is a mixture of isoparaffin and normal paraffin, wherein the content of isoparaffin is 95%, and the content of normal paraffin is 5%. The isoparaffin is iso-eicosane, and the normal paraffin is n-dodecane ;

[0069] (3) The surfactant is a mixture of polyene succinimide and fluorosurfactant, each with a mass percentage of 50%;

[0070] 2. Stirring: Stir the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com