Preparation for organic electroluminescence display

An organic light-emitting layer and electroluminescence technology, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as difficulties, difficulty in improving yield rate, application limitations, etc. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

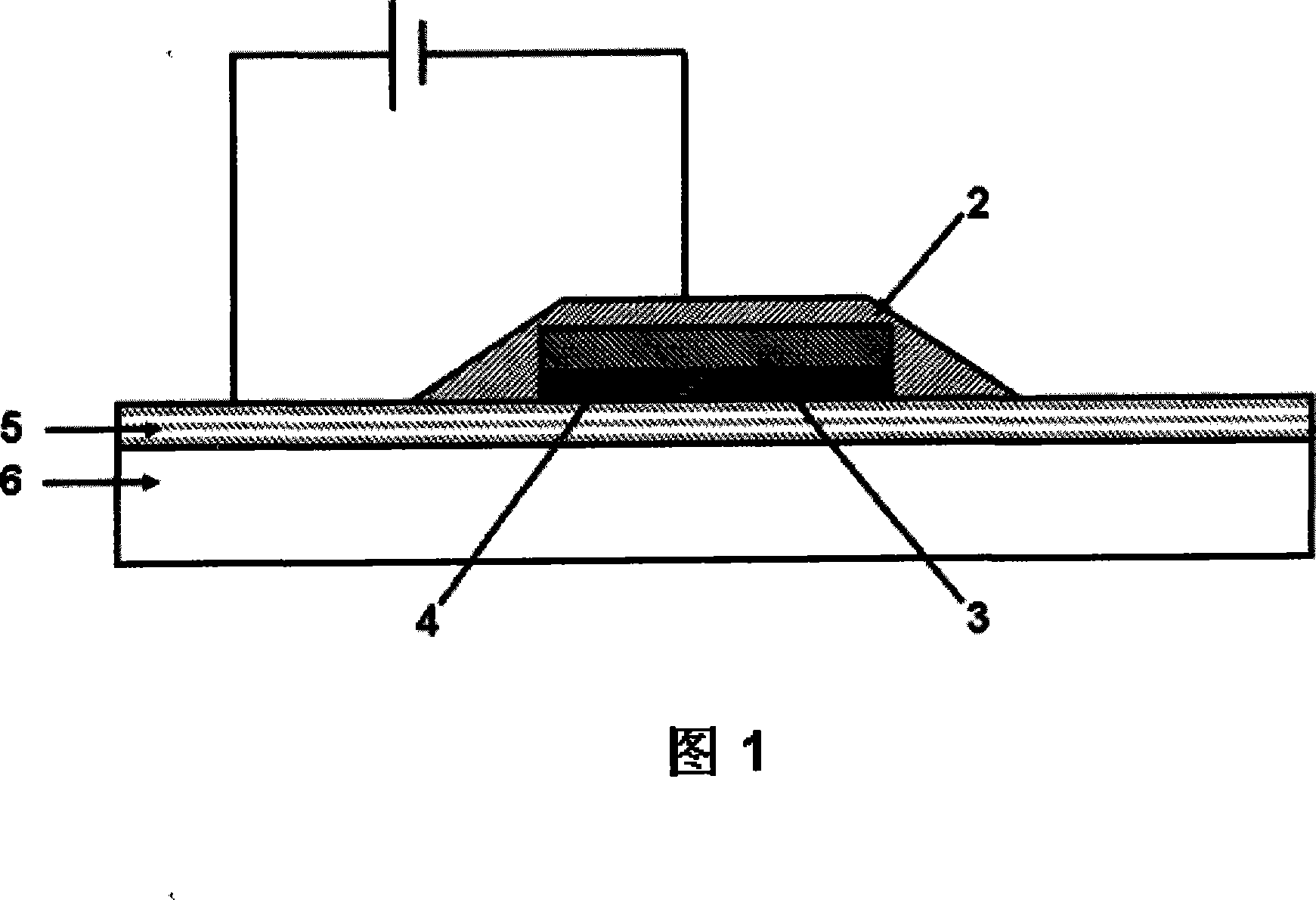

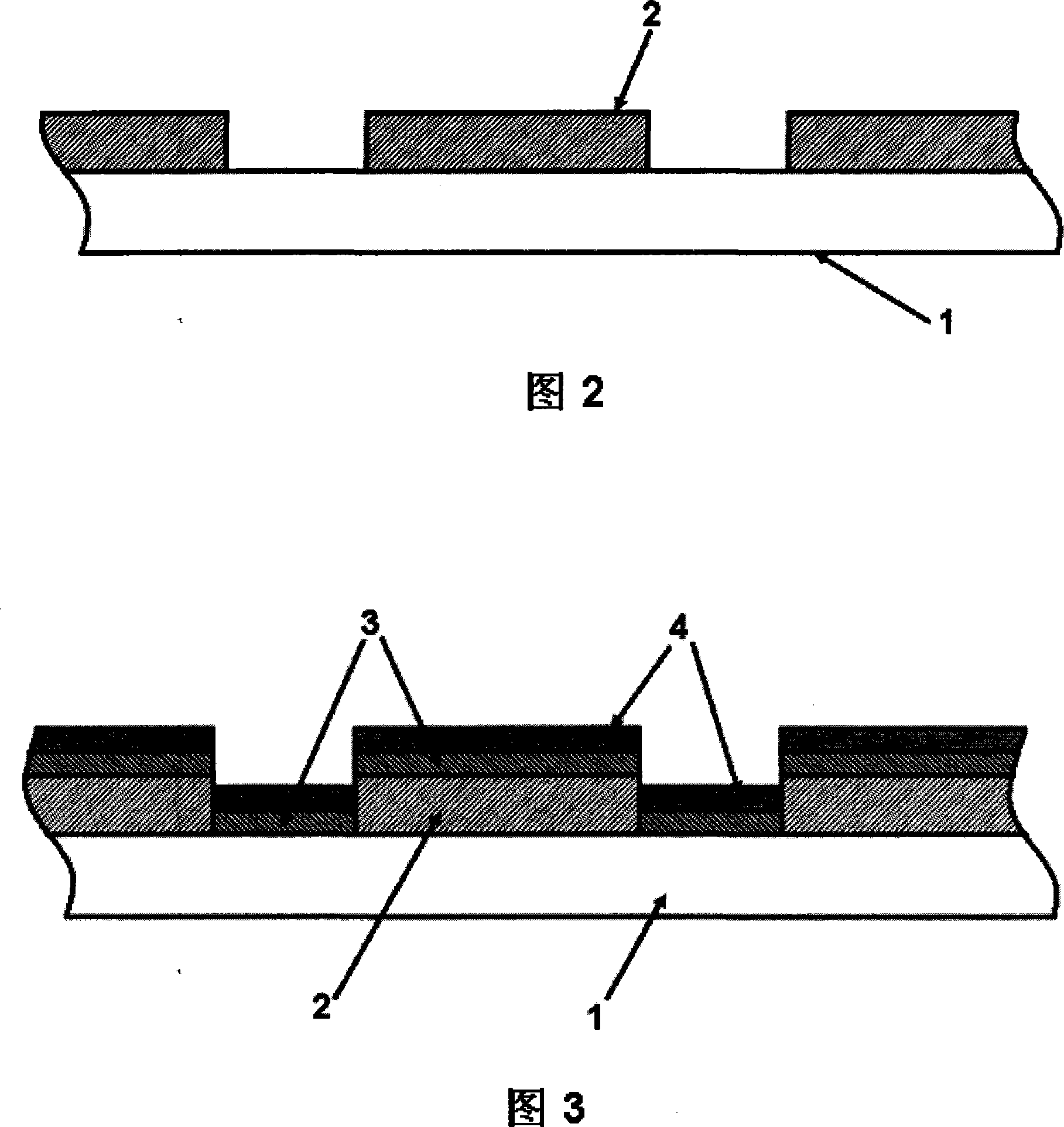

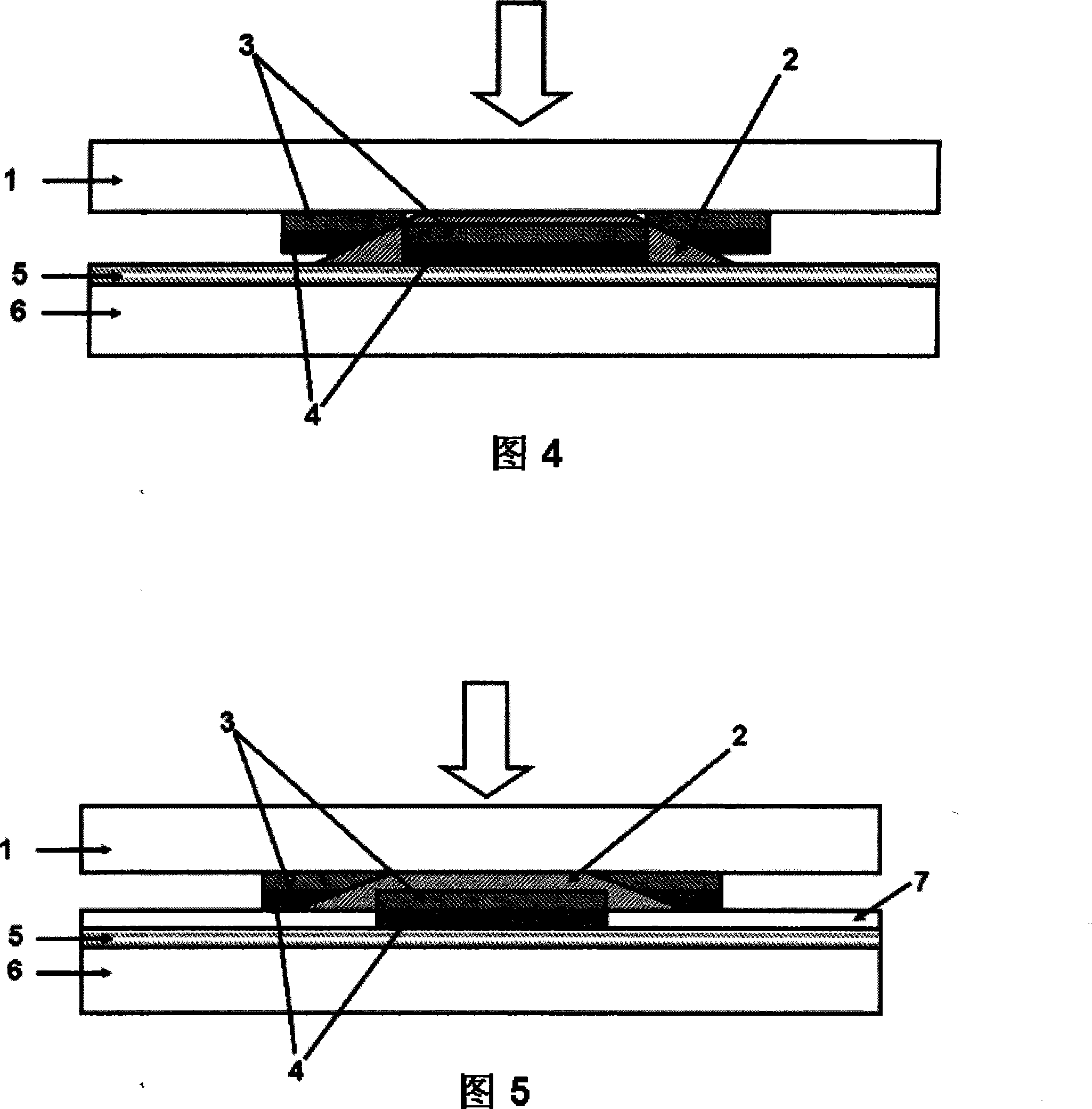

[0025] see Figure 1~4 A patterned conductive adhesive layer 2 is formed under the substrate 1 made of plastic, glass, metal or ceramic hard material or flexible material of plastic film by spin coating, screen printing or inkjet printing. The anisotropic conductive adhesive is made by mixing metal powder with a power function greater than 4eV and a polymer adhesive, and the metal powder is gold, silver, copper, aluminum, tin, indium, nickel or alloy powder thereof. On the anisotropic conductive adhesive layer 2, the first electrode layer 3 is sequentially formed by vapor deposition or sputtering, and the organic light-emitting layer 4 is formed by vapor deposition; It is formed of one or more layers of materials of metal, metal alloy or conductive oxide; the organic light-emitting layer is formed of carrier injection material, carrier transport material and light-emitting material itself. After the anisotropic conductive adhesive layer 2 of the substrate 1 is pressed against...

Embodiment 2

[0027] see figure 1 , 2 , 3, 5, using spin coating, screen printing or inkjet printing to form a patterned anisotropic conductive adhesive under the substrate 1 of hard materials such as plastics, glass, metal or ceramics or flexible materials such as plastic films. Mixture layer 2. The isotropic conductive adhesive 2 is made by mixing metal powder with a power function greater than 4eV and a polymer binder, and the metal powder is gold, silver, copper, aluminum, tin, indium, nickel or alloy powder thereof. On the isotropic conductive adhesive layer, the first electrode layer 3 is sequentially formed by evaporation or sputtering, and the organic light-emitting layer 4 is formed by evaporation; the first electrode layer is made of a metal that is conducive to carrier injection. , metal alloy or one or more layers of conductive oxide materials; the organic light-emitting layer is formed by carrier injection materials, carrier transport materials and the light-emitting material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com