Preparation of titanium-aluminum compound based composite material

A titanium-aluminum compound and composite material technology, applied in the field of material science, can solve the problems of low plasticity at room temperature, increase fiber damage, difficult plastic processing materials, etc., achieve great economic and social value, reduce thermal stress cracks, and reduce preparation temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Using the magnetron sputtering method to alternately sputter Ti films and Al films with a thickness of about 1 μm on SiC fibers, and prepare SiC composite wires with Ti and Al films stacked multiple times, such as figure 1 , 2 shown.

[0030] The preparation of composite materials is divided into two parts: the preparation of composite wires and the pressing of sheets. The composite wire is prepared by a double-target magnetron sputtering apparatus. First, the SiC fiber is wound on a special runner frame in parallel at a certain distance using a winding unit, and then the runner is loaded into the vacuum chamber of the magnetron sputtering apparatus. Two pairs of targets are installed with pure Ti and pure Al respectively, and the Ti film and Al film are sputtered on the surface of the SiC fiber in different time periods. When pressed, the interface reacts to form needle-like or flake-like Al 4 C 3 , and the good high-temperature deformation and diffusion ability of...

Embodiment 2

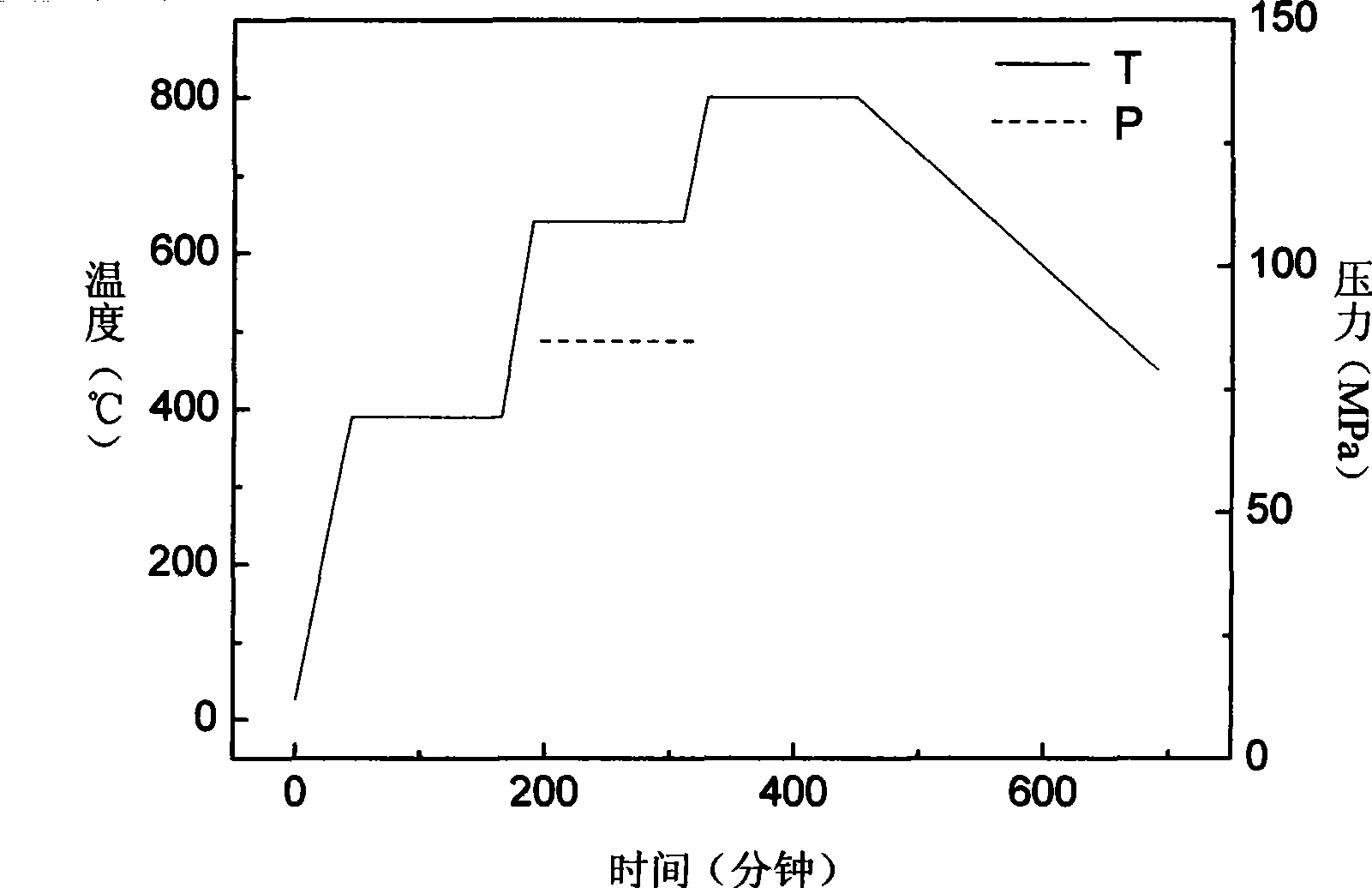

[0037] Example 2: Use the magnetron sputtering method to alternately sputter a Ti film and an Al film with a thickness of about 2 μm on the SiC fiber to prepare a SiC composite wire with multiple stacked Ti and Al films, seal it in a sheath and vacuumize it, and use The matrix coating fiber method is hot-pressed in a hot isostatic pressing furnace. The specific process is 600°C / 100MPa / 2h, and heat treatment at 800°C for 4 hours after taking it out.

[0038] For other technical details of this embodiment, refer to the content of Embodiment 1.

Embodiment 3

[0039] Example 3: Using the magnetron sputtering method to alternately sputter a Ti film with a thickness of about 1 μm and an Al film with a thickness of 3 μm on the SiC fiber, and use the matrix coating fiber method to form by quasi-isostatic hot pressing to prepare TiAl 3 The specific process is 600°C / 80MPa / 2h, +800°C / 80MPa / 4h.

[0040] In this embodiment, the volume ratio of Ti and Al is 1:3. For other technical details of this embodiment, refer to the content of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com