Thermalplastic resin multi-layer reinforced sheet, production method thereof and forming method for thermalplastic resin composite material forming article

A technology of thermoplastic resin and manufacturing method, applied in the field of thermoplastic resin multilayer reinforced sheet and its manufacture, and molding of thermoplastic resin composite material molding, capable of solving problems such as reduction of mechanical properties, hindrance of reinforcing fibers, reduction of mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0273] A thermoplastic resin multilayer reinforced sheet was manufactured using the following materials.

[0274] 〈Materials used〉

[0275] (Fiber bundles used in reinforcing fiber bundles)

[0276]Manufactured by Mitsubishi Rayon Corporation: TR50S-15K, fiber diameter about 7 μm, number of fibers 15,000 (resin used in thermoplastic resin sheets)

[0277] Manufactured by Mitsubishi Chemical Corporation: Nylon 6 resin film, film thickness 20 μm

[0278] (Fiber bundles used in thermoplastic resin fiber bundles for integration)

[0279] Manufactured by Toray Co., Ltd.: Nylon 6 multi-fiber rayon, 77dtex—24filaments

[0280] 〈Manufacturing process〉

[0281] (1) 16 reinforcing fiber bundles TR50S-15K were placed at intervals of 20 mm, and each reinforcing fiber bundle was opened to a width of 20 mm according to the method of simultaneously air-fiber-opening a plurality of them (see Patent Document 9).

[0282] (2) Each fiber-opened reinforcing fiber to have a width of 20 mm was...

Embodiment 2

[0289] A plurality of narrow-width thermoplastic resin reinforced sheets were obtained from the thermoplastic resin reinforced sheets obtained in (1) to (4) of Example 1, and a thermoplastic resin multilayer reinforced sheet was produced.

[0290] 〈Materials used〉

[0291] The reinforcing fiber bundles, the thermoplastic resin sheet, and the thermoplastic resin fiber bundles for integration are also the same as in Example 1.

[0292] 〈Manufacturing process〉

[0293] (1) Through (1) to (4) of Example 1, a thermoplastic resin reinforced sheet having a width of 320 mm was obtained.

[0294] (2) pass Figure 16 The production apparatus shown continuously cut the obtained thermoplastic resin reinforced sheet with a width of 10 mm to obtain 32 narrow-width thermoplastic resin reinforced sheets. At this time, as the cutting blade and the cutting method, a circular blade-shaped cutting blade that freely rotates in response to the movement of the thermoplastic resin reinforced sheet...

Embodiment 3

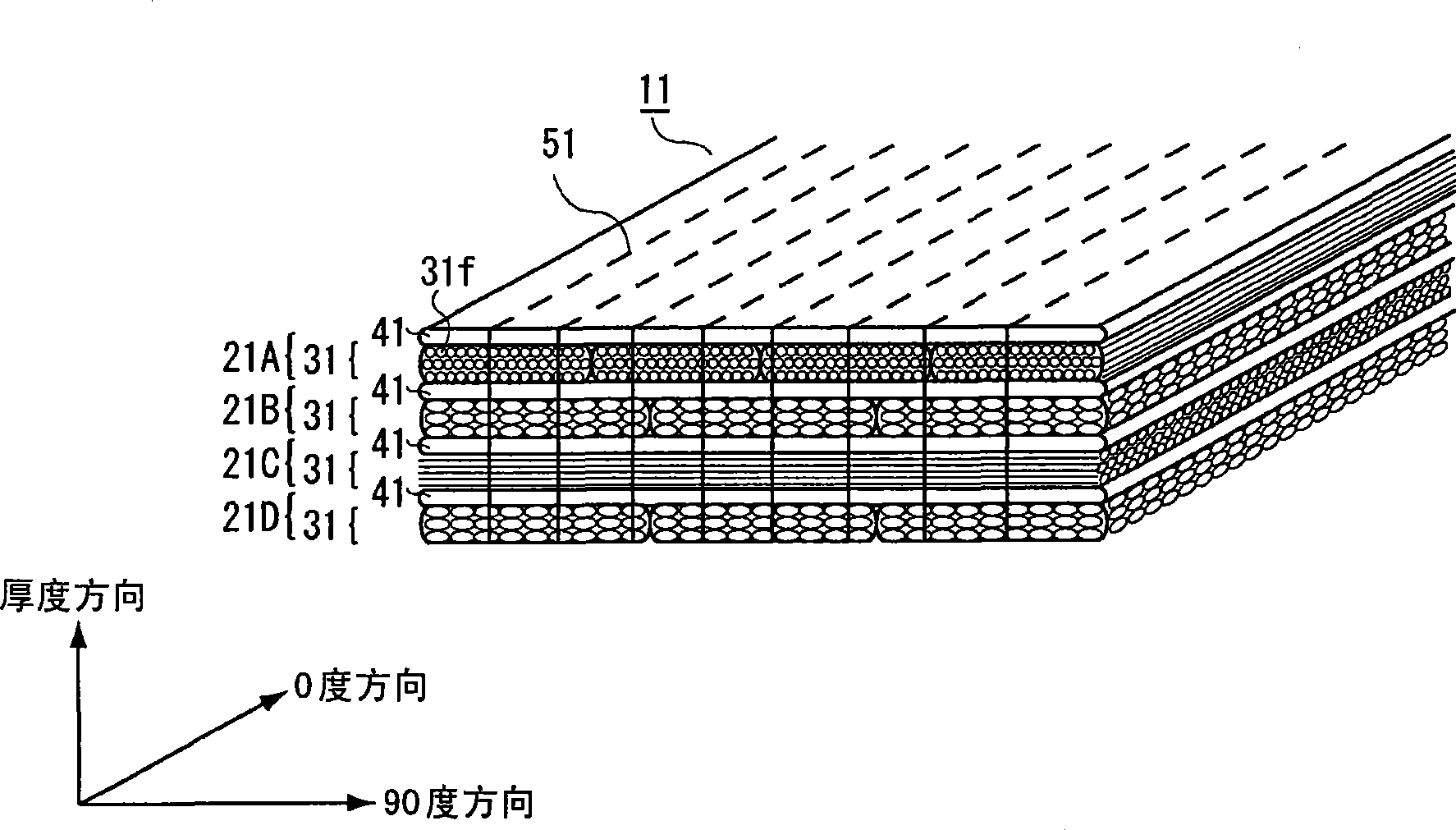

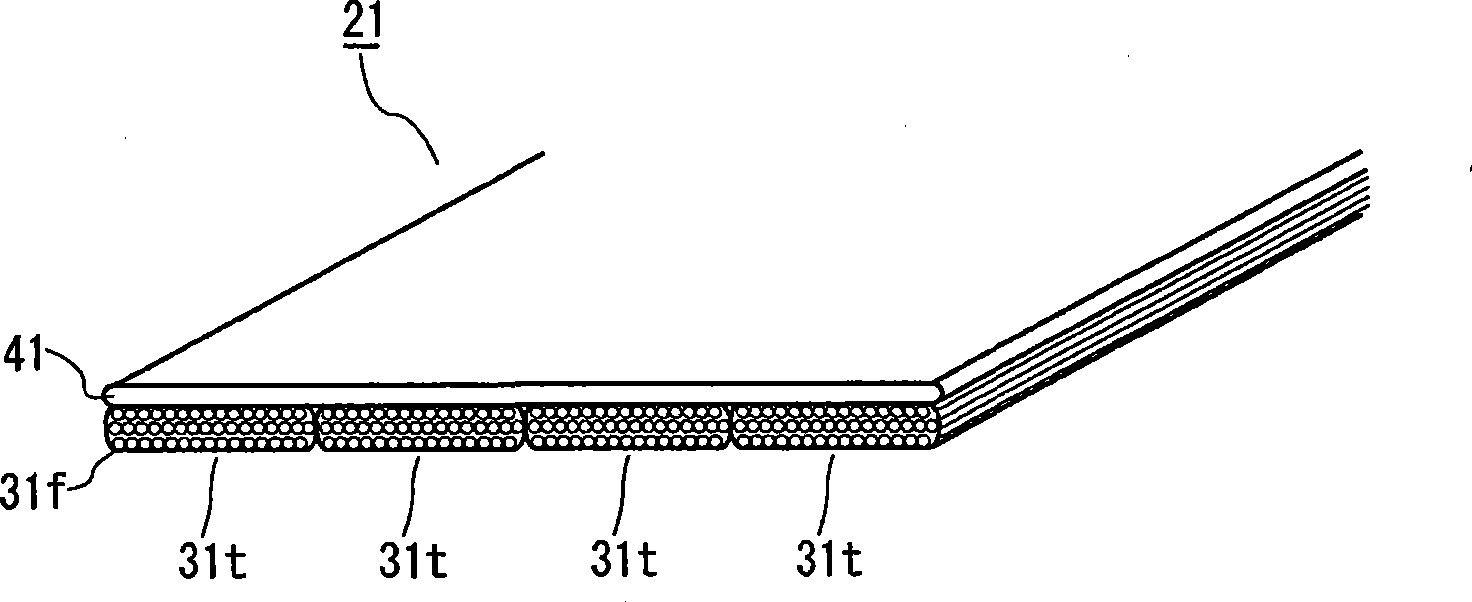

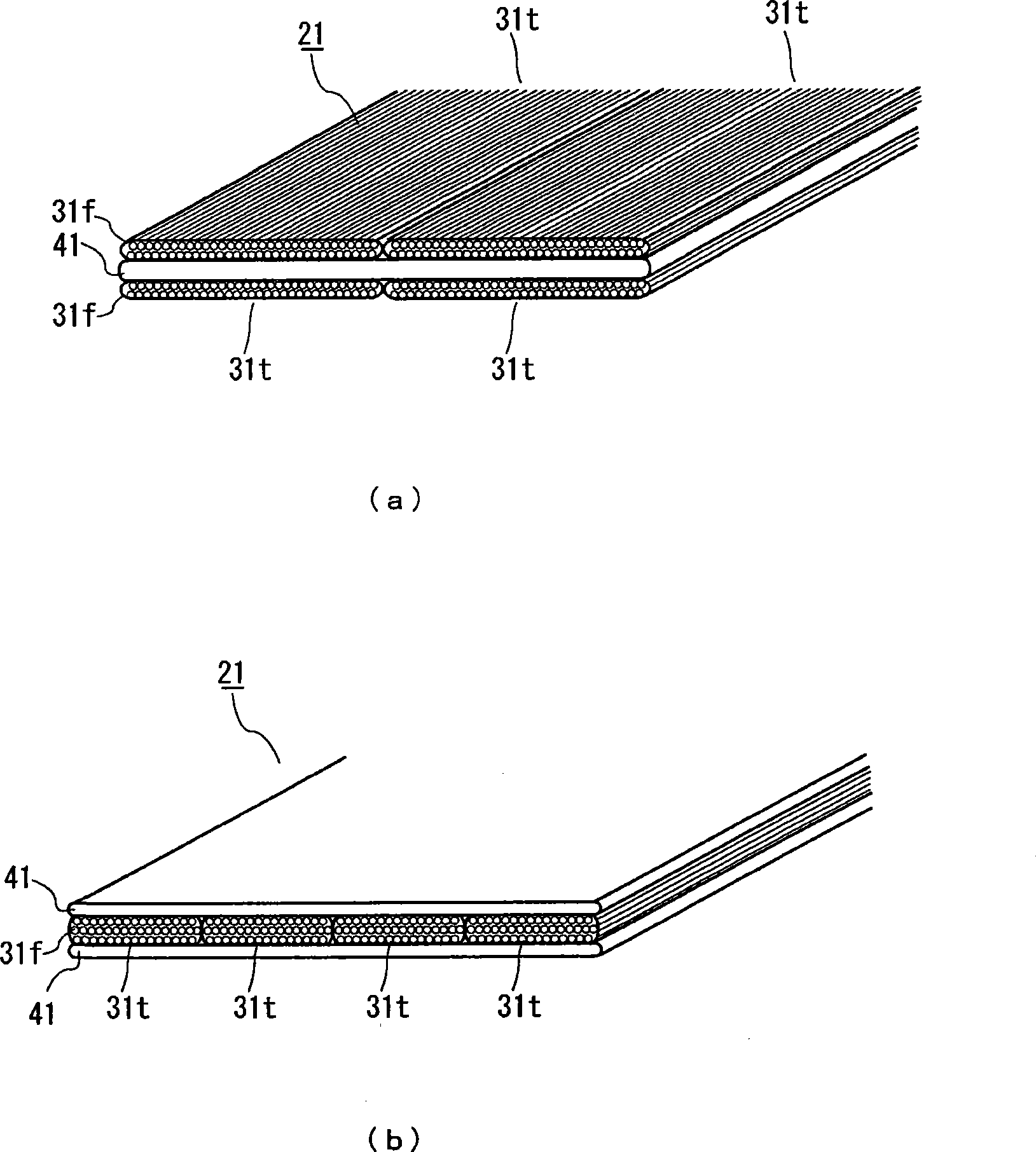

[0299] A plurality of thermoplastic resin reinforced sheets obtained in (1) to (4) of Example 1 were laminated and then heated and pressed to manufacture a thermoplastic resin multilayer reinforced sheet in which the layers were thermally welded and integrated. Sheet.

[0300] 〈Materials used〉

[0301] The reinforcing fiber bundle and the thermoplastic resin sheet are also the same as in Example 1.

[0302] 〈Manufacturing process〉

[0303] (1) Through (1) to (4) of Example 1, a thermoplastic resin reinforced sheet having a width of 320 mm was obtained.

[0304] (2) pass Figure 14 The production apparatus shown laminates the obtained thermoplastic resin reinforced sheets in the direction of 45 degrees, 0 degrees, -45 degrees and 90 degrees to form a laminated sheet with a width of 320mm, and passes through Figure 18 The manufacturing apparatus shown performs heating and pressing to obtain a thermoplastic resin multilayer reinforced sheet. As a manufacturing device, heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com