Anneal technique for improving battery electrical property

A technology of annealing process and electrical performance, applied in circuits, electrical components, climate sustainability, etc., can solve the problems of increasing contact resistance, difficult to optimize sub-processes, and difficult to optimize passivation temperature process, and achieve equipment Low investment, high production efficiency, and the effect of improving battery electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

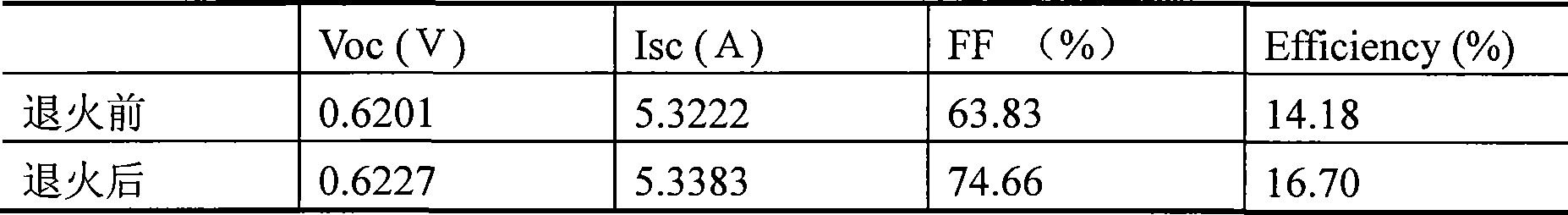

[0011] A 125×125mm monocrystalline cell manufactured by using low-frequency PECVD (PECVD generator frequency is 40kHz) to deposit silicon nitride anti-reflection film and manufacture based on screen printing is placed in a diffusion furnace tube (gas flow can be controlled) for annealing treatment, annealing The temperature is 370°C, the annealing time is 18min, the annealing atmosphere is a mixed gas of nitrogen and hydrogen, V H2 :V N2 =5:27, the efficiency change after annealing is shown in Table 1.

[0012]

Embodiment 2

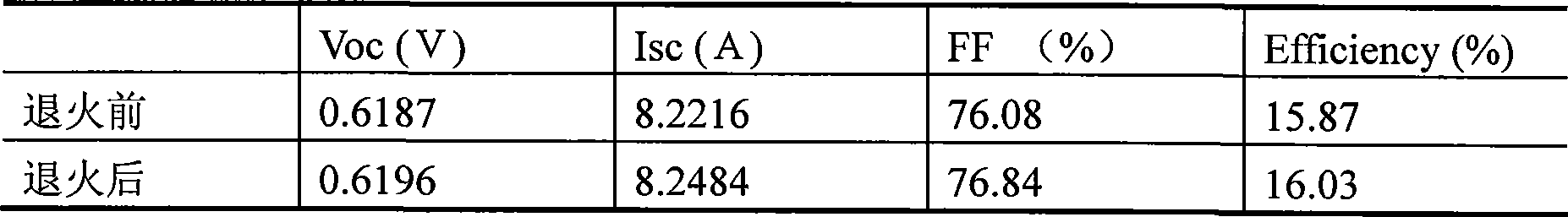

[0014] A 156×156mm polycrystalline cell manufactured by using low-frequency PECVD (the PECVD generator frequency is 40kHz) to deposit silicon nitride anti-reflection film and manufacture based on screen printing is annealed in a diffusion furnace tube (the gas flow can be controlled), and the annealing temperature is The temperature is 330°C, the annealing time is 35min, the annealing atmosphere is a mixed gas of nitrogen and hydrogen, V H2 :V N2 =1:9, the efficiency change after annealing is shown in Table 2

[0015] Table 2

[0016]

Embodiment 3

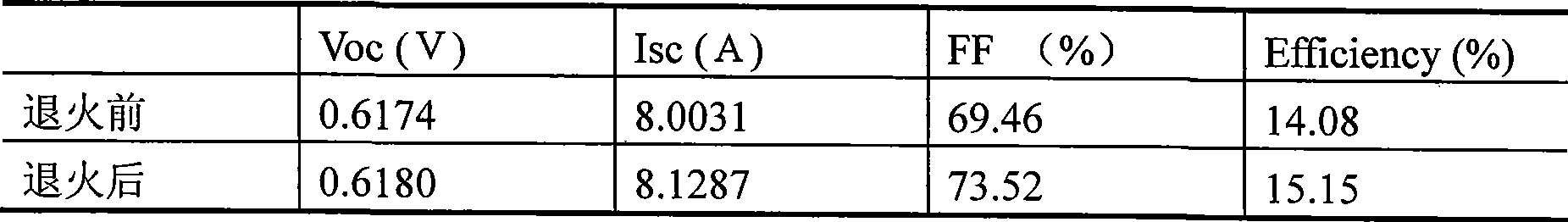

[0018] A 156×156mm polycrystalline cell manufactured by using low-frequency PECVD (the PECVD generator frequency is 40kHz) to deposit silicon nitride anti-reflection film and manufacture based on screen printing is annealed in a diffusion furnace tube (the gas flow can be controlled), and the annealing temperature is The temperature is 395°C, the annealing time is 18min, and the annealing atmosphere is a mixed gas of nitrogen and hydrogen, V H2 :V N2 =1:9, the change in efficiency after annealing is shown in Table 3.

[0019] table 3

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com