Oil in water-oil in oil-water in oil method for preparing microballoons

An oil-in-oil and water-in-oil technology is applied in the field of oil-in-water-oil-in-oil-water-in-oil preparation of microspheres, which can solve the problems of incomplete release, easy sudden release of drugs, and low encapsulation rate, etc. Good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of PLGA Microspheres Loaded with Small Molecule Drugs

[0031] (1) Prepare a drug solution, and dissolve the small molecule drug in water directly or by adding excipients;

[0032] In this embodiment, the small molecule drugs used are tumor chemotherapy drugs (tumor chemotherapy drugs are selected from: doxorubicin, cyclophosphamide, dactinomycin, bleomycin, daunorubicin, doxorubicin, epirubicin Mitomycin, Mitomycin, Methotrexate, Fluorouracil, Carboplatin, Carmustine (BCNU), Semustine, Cisplatin, Etoposide, Camptothecin and its derivatives, Cholesterol , paclitaxel and its derivatives, docetaxel and its derivatives, vinblastine, vincristine, tamoxifen, etoposide, piposulfan, cyclophosphamide, or flutamide and its derivatives; sustained release Microspheres can be loaded with one or more of the above drugs;) or antibiotics (antibiotics are selected from cyclosporine, levofloxacin, ofloxacin, or epinastine hydrochloride; slow-release microspheres ...

Embodiment 2

[0045] Example 2: Preparation of PLGA microspheres loaded with biomacromolecular drugs

[0046] (1) Prepare a biomacromolecular drug solution, and dissolve the biomacromolecular drug in water by adding auxiliary materials;

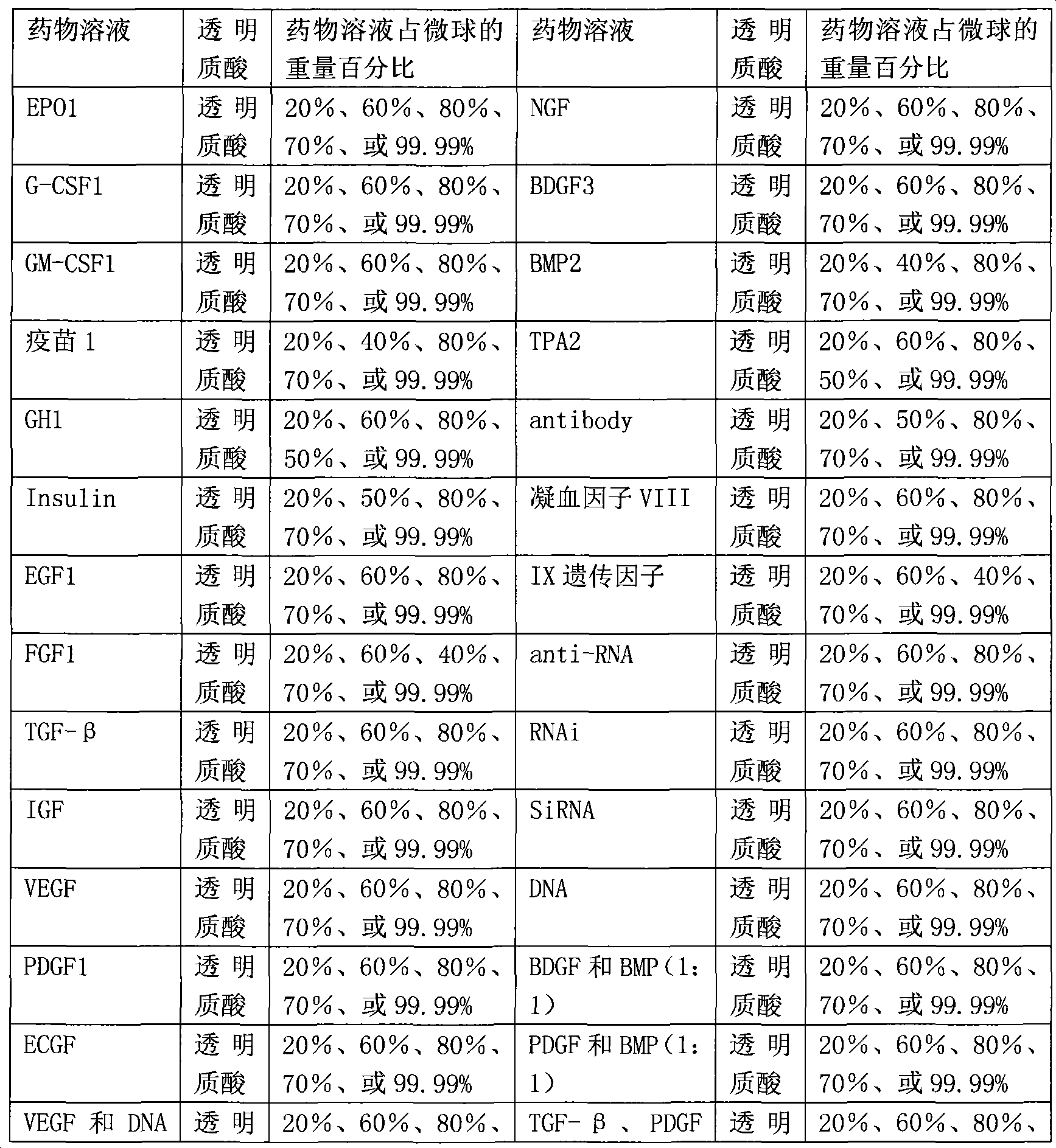

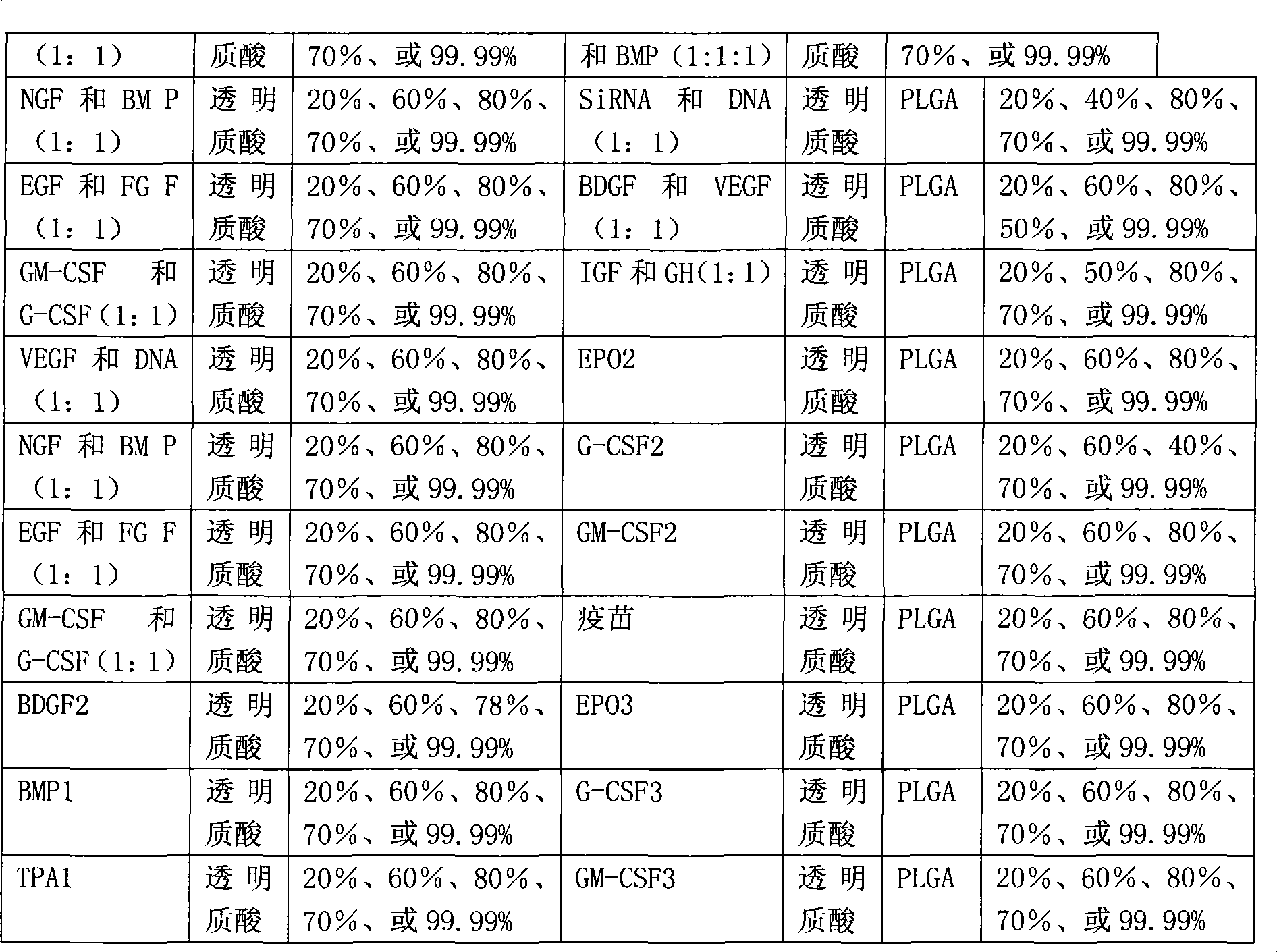

[0047] In this example, the biomacromolecular drugs used are erythropoietin (EPO), recombinant human granulocyte colony-stimulating factor (G-CSF), granulocyte-macrophage colony-stimulating factor (GM-CSF), vaccines, Interferon (INF), growth hormone (GH), insulin (Insulin), epidermal growth factor (EGF), fibroblast growth factor (FGF), transforming growth factor (TGF-β), insulin-like growth factor (IGF), Vascular endothelial growth factor (VEGF), platelet growth factor (PDGF), endothelial growth factor (ECGF), nerve growth factor (NGF), bone-derived growth factor (BDGF), bone morphogenic protein (BMP), tissue polypeptide antigen ( TPA), antibody (antibody), coagulation factor VIII (VIII), genetic factor IX, antisense nucleotide (anti-RNA), small molecule ...

Embodiment 3

[0059] Example 3: Preparation of PLA Microspheres Loaded with Small Molecule Drugs

[0060] Step (1) is the same as in Embodiment 1.

[0061] (2) According to the dichloromethane, acetonitrile or ethyl acetate solution of the drug solution and PLA: 1:1, 1:2, 1:3, 1:4, 1:5, 1:6, 1:7, 1: 8. 1:9, 1:10 equal ratio stirring, vortex or ultrasonic for 1-5 minutes to form a uniform suspension that is water in oil (W / O 1 ) lotion;

[0062] Steps (3), (4), (5) are the same as in Embodiment 1.

[0063] The microsphere that present embodiment obtains, its specific component ratio is as follows:

[0064] drug solution

[0065] Epirubicin 1

[0066] The microspheres prepared by this method can be used for diseases requiring long-term treatment, especially for diseases requiring local treatment such as tumor vascular embolization microspheres. The encapsulation rate of the microspheres prepared by this method can reach at least 70%, and the burst release is small and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com