Fructose and oligo-fructose production method using garlic fructosan hydrolase

A fructooligosaccharide and hydrolase technology, which is applied in application, food preparation, food science and other directions, can solve the problem of high production cost, and achieve the effect of reducing the cost of product raw materials, reducing environmental pollution, and reducing equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

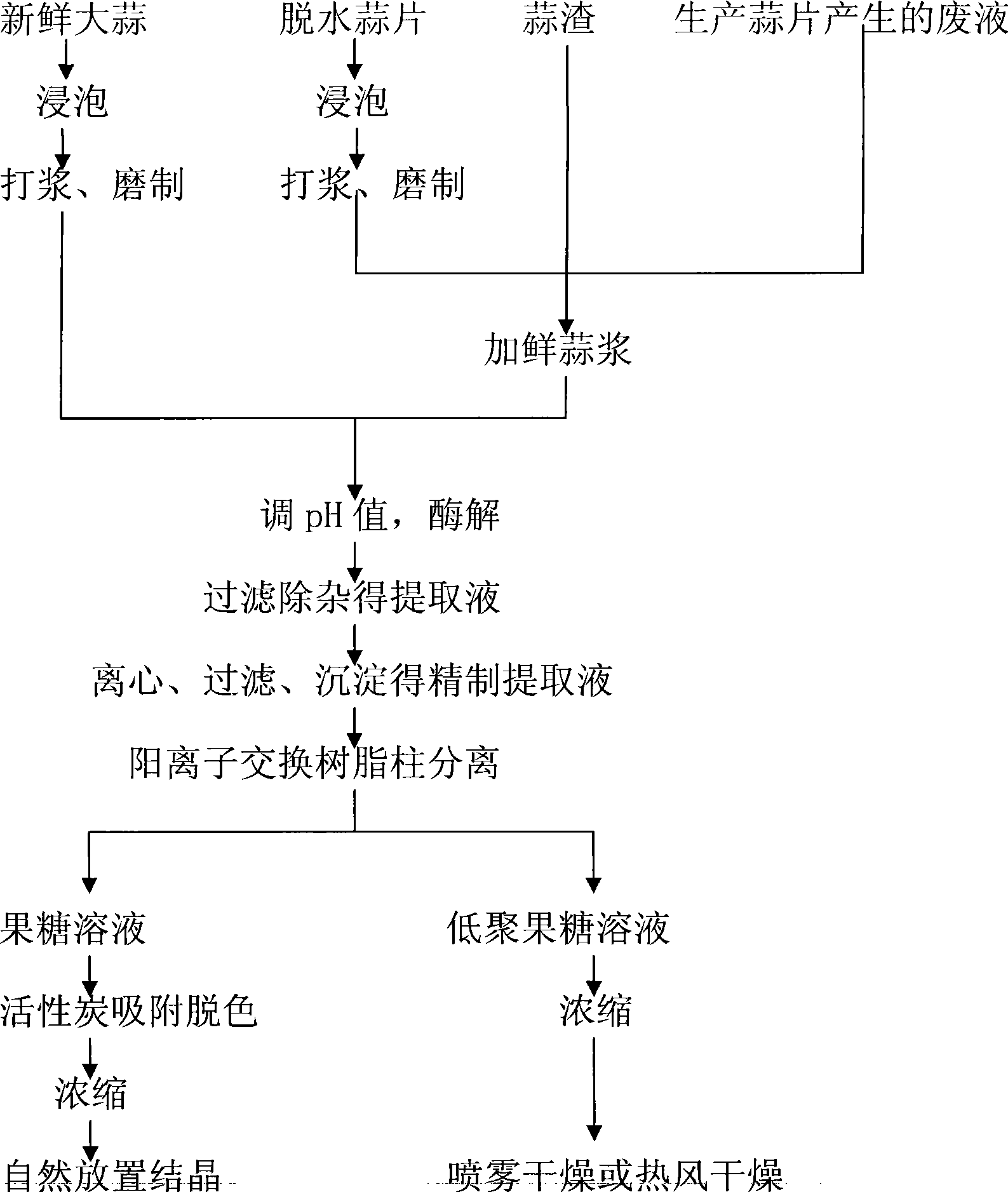

[0026] With fresh garlic as raw material, such as figure 1 Shown technological process, specifically carry out according to the following steps:

[0027] (1) Make garlic paste from raw garlic: put 10 kg of fresh garlic cloves in 25 kg of drinking water, soak for 4 hours, rinse with running water to remove impurities such as soil and garlic skin; mix peeled garlic cloves with 5-25 kg Add water to the beater together to make garlic pulp of 100-150 mesh;

[0028] (2) Preparation of fructose and fructo-oligosaccharide extracts: adjust pH=4 with citric acid, etc., and react for 3 hours at 30° C.; filter the processed solution after the reaction with garlic pulp through a 250-mesh filter cloth to obtain a crude extract;

[0029] (3) Preparation of fructose and fructo-oligosaccharide refining extract: the crude extract obtained in step (2) was centrifuged at 4000rpm for more than 20 minutes, and the gained supernatant was filtered through an inorganic membrane with a molecular weigh...

Embodiment 2

[0034] With fresh garlic as raw material, such as figure 1 Shown technological process, specifically carry out according to the following steps:

[0035] (1) Make garlic paste from raw garlic: put 10 kg of fresh garlic cloves in 50 kg of drinking water, soak for 8 hours, rinse with running water to remove impurities such as soil and garlic skin; mix peeled garlic cloves with 5-25 kg Add water to the beater together to make garlic pulp of 100-150 mesh;

[0036] (2) Preparation of fructose and fructo-oligosaccharide extracts: adjust pH=6 with citric acid, etc., and react for 2.5 hours at 20° C.; filter garlic pulp with a bag filter to obtain a crude extract;

[0037](3) Preparation of fructose and fructo-oligosaccharide refining extract: the crude extract obtained in step (2) was centrifuged at 3000rpm for more than 20 minutes, and the obtained supernatant was filtered by a plate and frame press with a pressure of 3MPa, and the permeate It is a transparent refined extract of f...

Embodiment 3

[0042] With dehydrated garlic slices as raw material, proceed as follows:

[0043] (1) Make garlic pulp from raw garlic: soak dehydrated garlic slices in 10 times drinking water for 1 hour; use a beater to make garlic pulp with 100-150 mesh, and add 5 kg fresh garlic paste;

[0044] (2) Preparation of fructose and fructo-oligosaccharide extract: adjust pH=6 with citric acid etc., adjust temperature at 50° C. and react for 0.5 hour; filter garlic pulp with 250-mesh filter cloth to obtain crude extract;

[0045] (3) Preparation of fructose and fructo-oligosaccharide refining extract: the crude extract obtained in step (2) was centrifuged at 4000rpm for more than 20 minutes, and the resulting supernatant was filtered through an inorganic membrane with a molecular weight cut-off of 50,000 Daltons. The liquid is a transparent fructose and fructooligosaccharide solution;

[0046] (4) Separation of fructose and fructo-oligosaccharides: 5 kilograms of cation exchange resins are proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com