Insulated trench gate electrode bipolar type transistor

A technology of bipolar transistors and insulated gates, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of increased amplification factor of PNP transistors, reduced safe working area, and reduced anti-latch-up ability, so as to reduce contact Resistance, lower temperature rise, and improved high-temperature latch-up resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

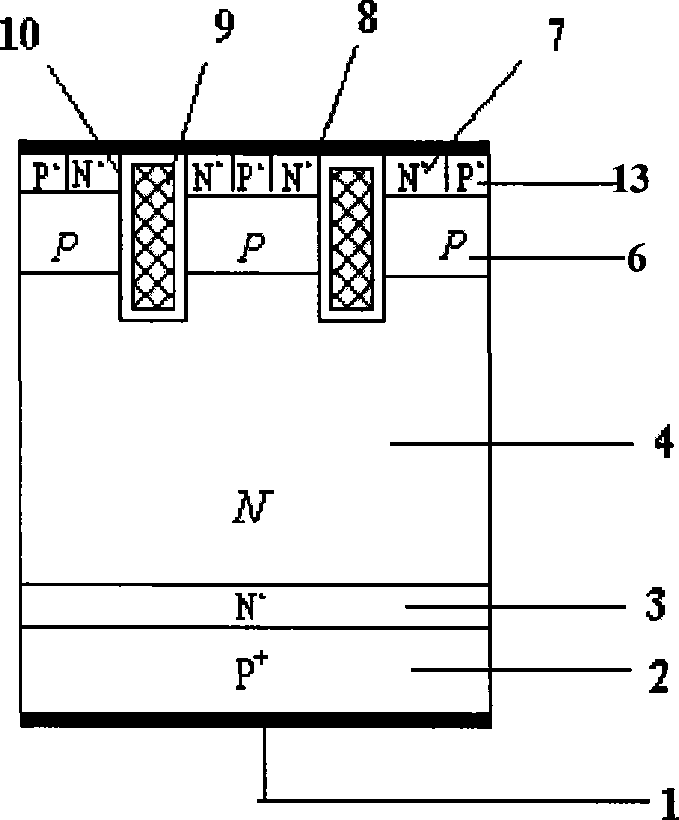

[0036] The use of the hole collection region structure and the trench metal emitter structure of the present invention can greatly weaken the parasitic thyristor effect, reduce the emitter contact resistance, improve the heat dissipation characteristics of the device, and significantly increase the safe working area of the device, especially the device The high temperature anti-latch-up ability has been greatly improved. With the development of semiconductor technology, more power devices with low voltage drop, high current and high reliability can be produced by adopting the invention.

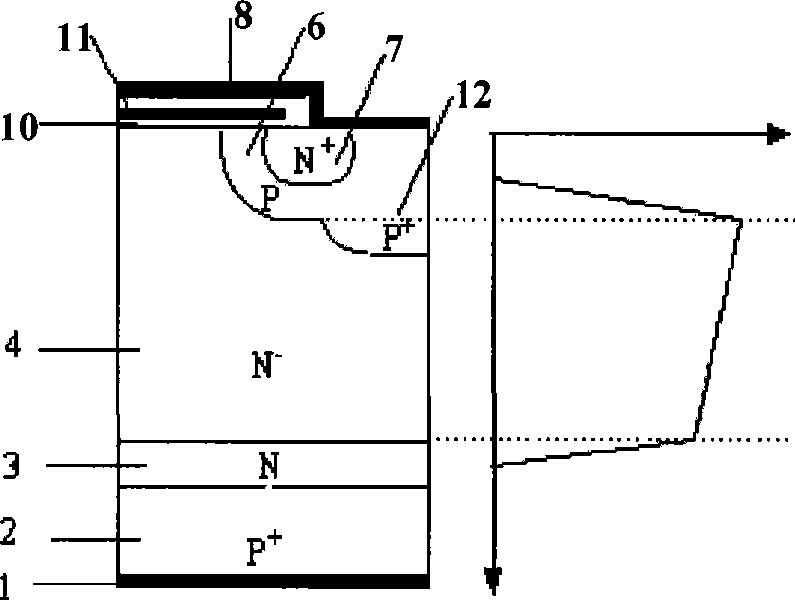

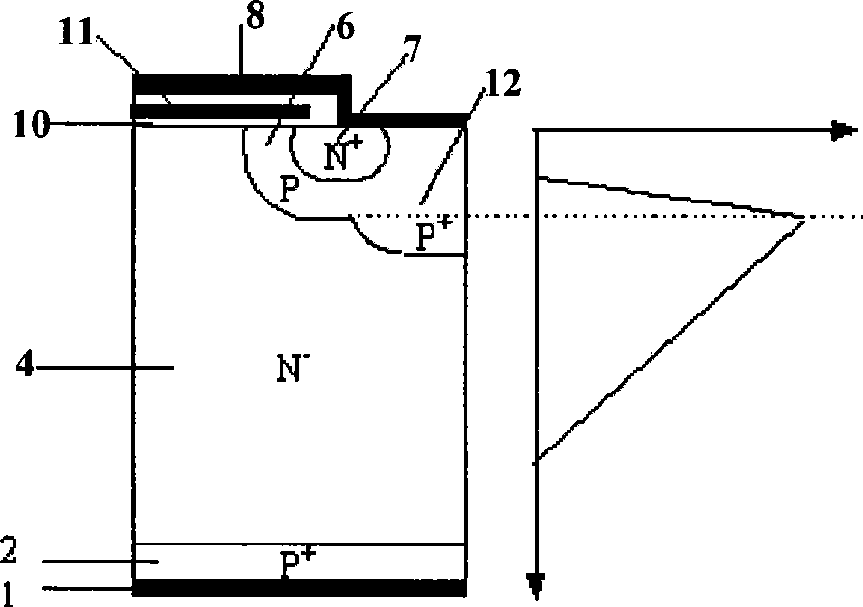

[0037] Trench insulated gate bipolar transistors that introduce a hole-collecting region structure and a trench metal emitter structure, such as Figure 4 shown, including metallized collector 1, P + Substrate 2, N + buffer layer 3, N - Base 4, P + Hole collection region 5, P-type base region 6, N + Source region 7 , trench metal emitter 8 , trench gate 9 and gate oxide layer 10 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com