Closed photocatalyst carrier structure and its pollutant treatment system

A photocatalyst, closed technology, applied in the field of closed photocatalyst carrier structure and its pollutant treatment system, can solve the problems of weak processing capacity, reducing the contact probability between pollutants and photocatalyst, and small fluid resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

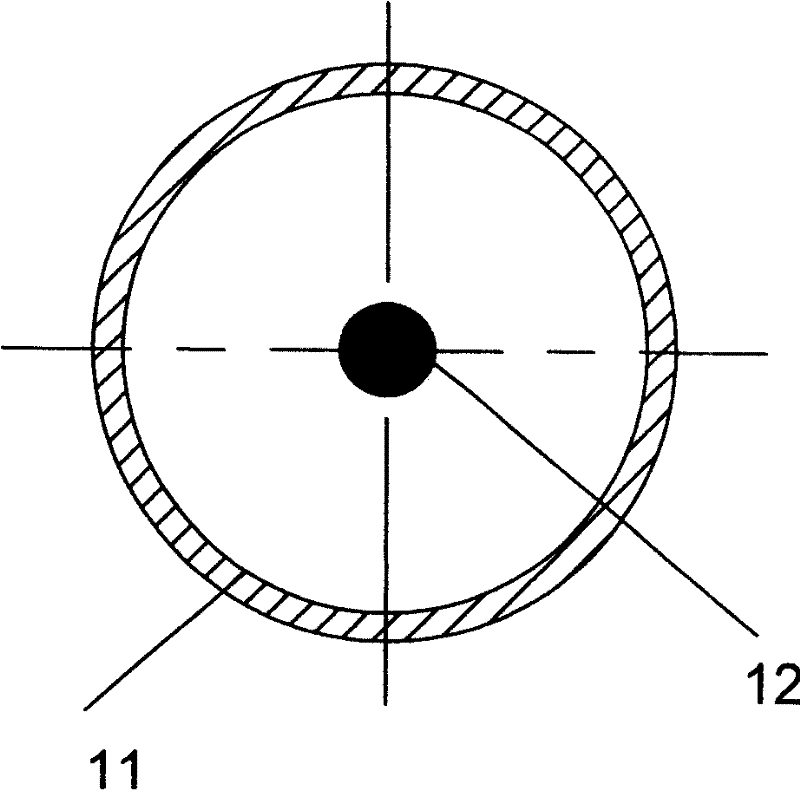

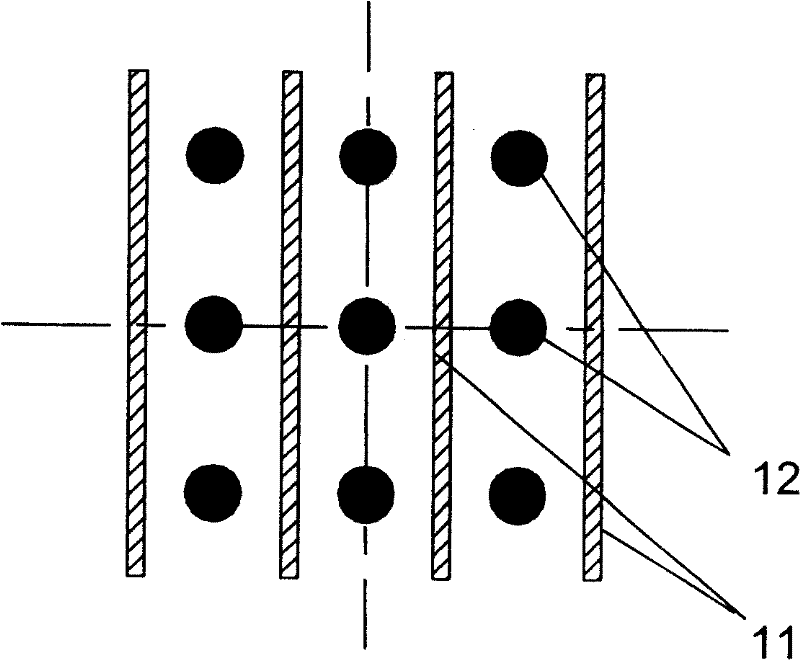

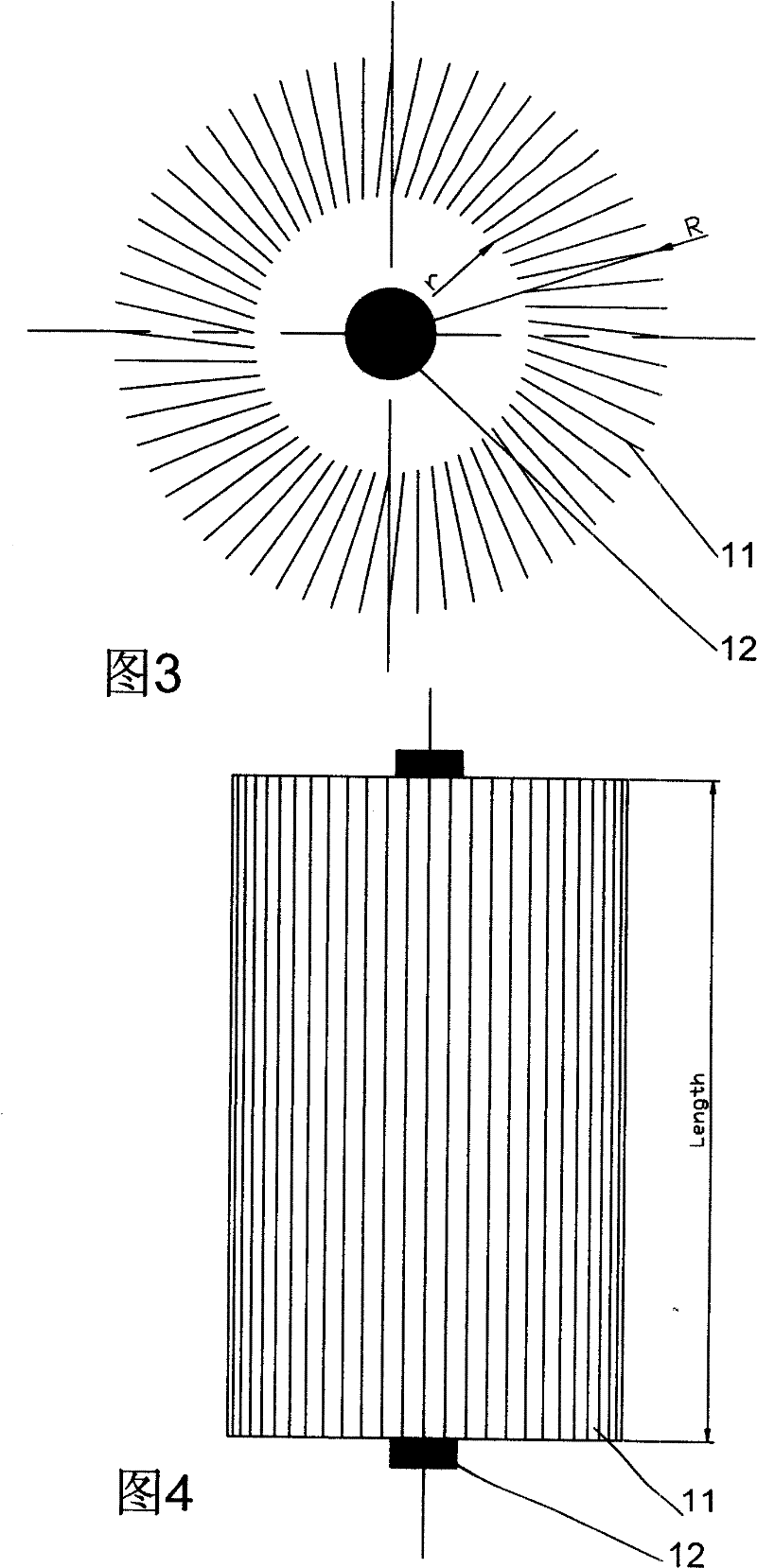

[0036] exist Figure 10 In shown embodiment 1, photocatalyst carrier structure comprises photocatalyst carrier structural part 10 and barrier plate 14, and catalyst carrier structural part 10 comprises several photocatalyst carrier porous material sheets 11 and ultraviolet light source 12, and barrier plate 14 is arranged on photocatalyst carrier porous material On both sides of the gap formed between the thin plates 11, when the pollutant fluid flows from the A side of the photocatalyst carrier structural part 10 to the B side, due to the blocking effect of the barrier plate 14, the pollutant fluid does not flow from between the photocatalyst carrier porous material thin plates 11. The formed gap directly passes through, but flows through the pores of the photocatalyst carrier porous material sheet. In this embodiment, the barrier plate 14 is disposed on one side of the thin plate 11 and forms a semi-closed cavity with the thin plate 11 . The photocatalyst carrier structure ...

Embodiment 2

[0038] exist Figure 11 In shown embodiment 2, photocatalyst carrier structure comprises photocatalyst carrier structural part 10 and barrier plate 14, and photocatalyst carrier structural part 10 comprises some photocatalyst carrier porous material sheet 11 and ultraviolet light source 12, and barrier plate 14 is arranged on photocatalyst carrier porous material sheet On both sides of the gap formed between 11, when the pollutant fluid flows from the A side of the photocatalyst carrier structural part 10 to the B side, due to the blocking effect of the barrier plate 14, the pollutant fluid does not flow from between the photocatalyst carrier porous material sheet 11. The formed gap directly passes through, but flows through the pores of the photocatalyst carrier porous material sheet 11 . In this embodiment, the barrier plate 14 is disposed on one side of the thin plate 11 and forms a semi-closed cavity with the thin plate 11 . The photocatalyst carrier structure component 1...

Embodiment 3

[0040] exist Figure 12 In shown embodiment 3, photocatalyst carrier structure comprises photocatalyst carrier structural part 10 and barrier plate 14, and photocatalyst carrier structural part 10 comprises some photocatalyst carrier porous material sheet 11 and ultraviolet light source 12, and barrier plate 14 is arranged on photocatalyst carrier porous material On both sides of the gap formed between the thin plates 11, when the pollutant fluid flows from the A side of the photocatalyst carrier structure 10 to the B side, due to the blocking effect of the barrier plate 14, the pollutant fluid does not flow from between the photocatalyst carrier porous material thin plates 11. directly pass through the formed gap, but flow through the pores of the photocatalyst carrier porous material sheet. In this embodiment, the barrier plate 14 is disposed on one side of the thin plate 11 and forms a partly fully closed and partly semi-closed cavity with the thin plate 11 . The photocata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com