Cooling paper tube with spiral filling structure as well as preparation method and application of cooling paper tube

A technology of spiral tubes and paper tubes, which is applied in the field of paper product processing, can solve the problems of increasing heat dissipation time, complex internal structure of paper tubes, and poor use effects, so as to increase residence time, improve heat dissipation and cooling effect, and is suitable for large The effect of mass production processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

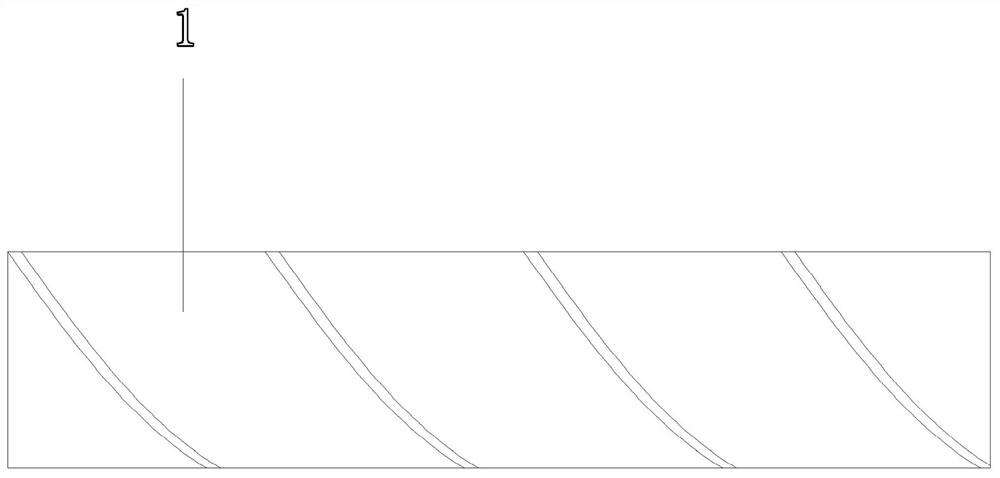

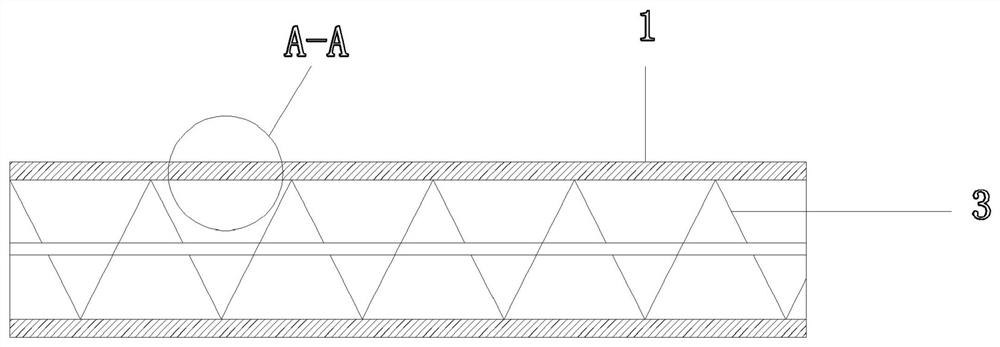

[0040] Such as figure 1 , 2 , 3, a cooling paper tube with a spiral filling structure described in this embodiment includes a tube wall and a content mechanism; the content mechanism is a spiral blade 3, and the outer edge of the spiral blade 3 is fixed On the inner surface of the pipe wall, extending along the axis of the pipe wall at equidistant axial intervals, the axial dimension of the helical blade 3 is less than or equal to the axial length of the pipe wall.

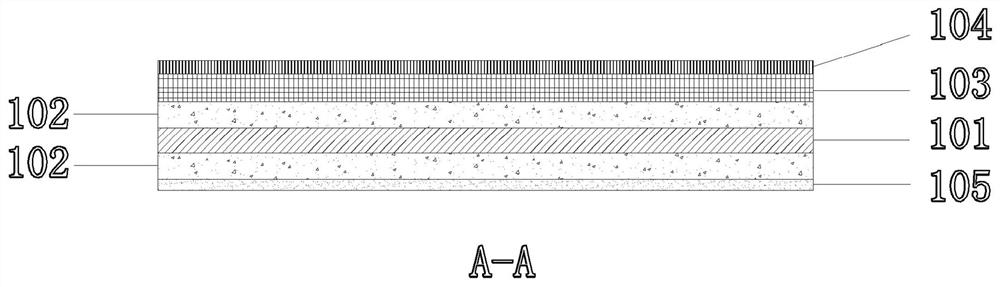

[0041] The pipe wall is a spiral pipe wall 1, which is composed of base material and reinforcing material; wherein the base material is an ordinary paper tape 101, and aluminum foil 102 is attached to both sides of it, and the outer aluminum foil 102 is also laminated in sequence There is a reinforcing fiber layer 103 and a heat exchange coating 104; the matrix material and the reinforcing material form a composite belt, and a hot melt adhesive layer 105 is arranged on the inner side of the composite belt, that i...

Embodiment 2

[0044] Such as Figure 4 , 5 As shown, the structure of a cooling paper tube with a spiral filling structure described in this embodiment is basically the same as that described in Example 1, the difference is that the tube wall is a seamless tube wall 2, and a heat exchange tube is attached to the outside The aluminum foil 201, the strength and hardness of the seamless tube wall is sufficient, only need to ensure the heat dissipation performance, the heat exchange aluminum foil 201 and the heat exchange coating 202 are attached on the outside, and the glue layer 203 is coated on the inner wall of the paper tube.

[0045] The helical blade 3 arranged inside the pipe wall is a shaftless helical blade.

[0046] The special-shaped helical blade 3 is arranged inside the tube wall. The upper and lower surfaces of the special-shaped helical blade 3 are provided with irregular contiguous pits, and solid slow-release gel is filled in the pits.

Embodiment 3

[0048] A cooling paper tube with a spiral filling structure is prepared according to the following steps:

[0049] ① To make the spiral pipe wall, the manufacturing process is as follows:

[0050] a. Lay ordinary paper tape, aluminum foil, and reinforced fiber layer together and then press to form a composite paper tape;

[0051] b. Mix the raw materials for making the spiral blade evenly in proportion and heat-melt them;

[0052] c. The spiral tube wall is formed by winding the composite paper tape obtained in step a on the winding mandrel according to a specific winding angle; the extrusion die of the spiral blade is integrated inside the winding mandrel, and the discharge port is arranged at At the front end of the winding mandrel, the melted raw material is extruded through the molding die under the action of mechanical extrusion; the composite paper tape is sent to the winding mandrel by the paper feed roller, and it does not rotate itself, but Driven by the rotation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com