Method for preparing metallic nickel nano granule doped MgB2 superconduction material by reduction method

A nanoparticle and superconducting material technology, applied in the field of superconductivity, can solve the problems of expensive metal nanoparticles, difficult nanoparticle doping, and reduced doping effect, so as to achieve critical current density, not easy to agglomerate, doping Mixed effect obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

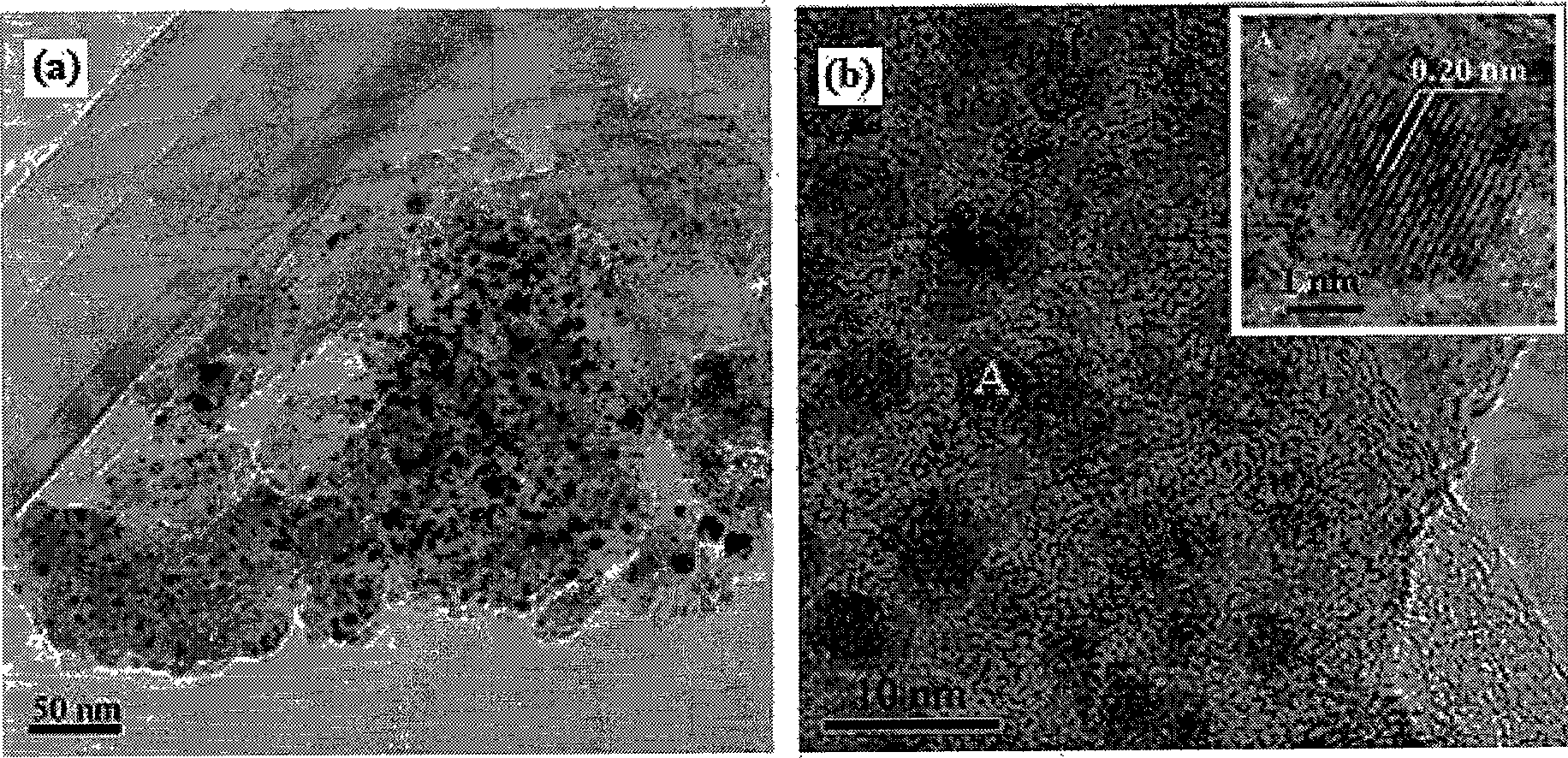

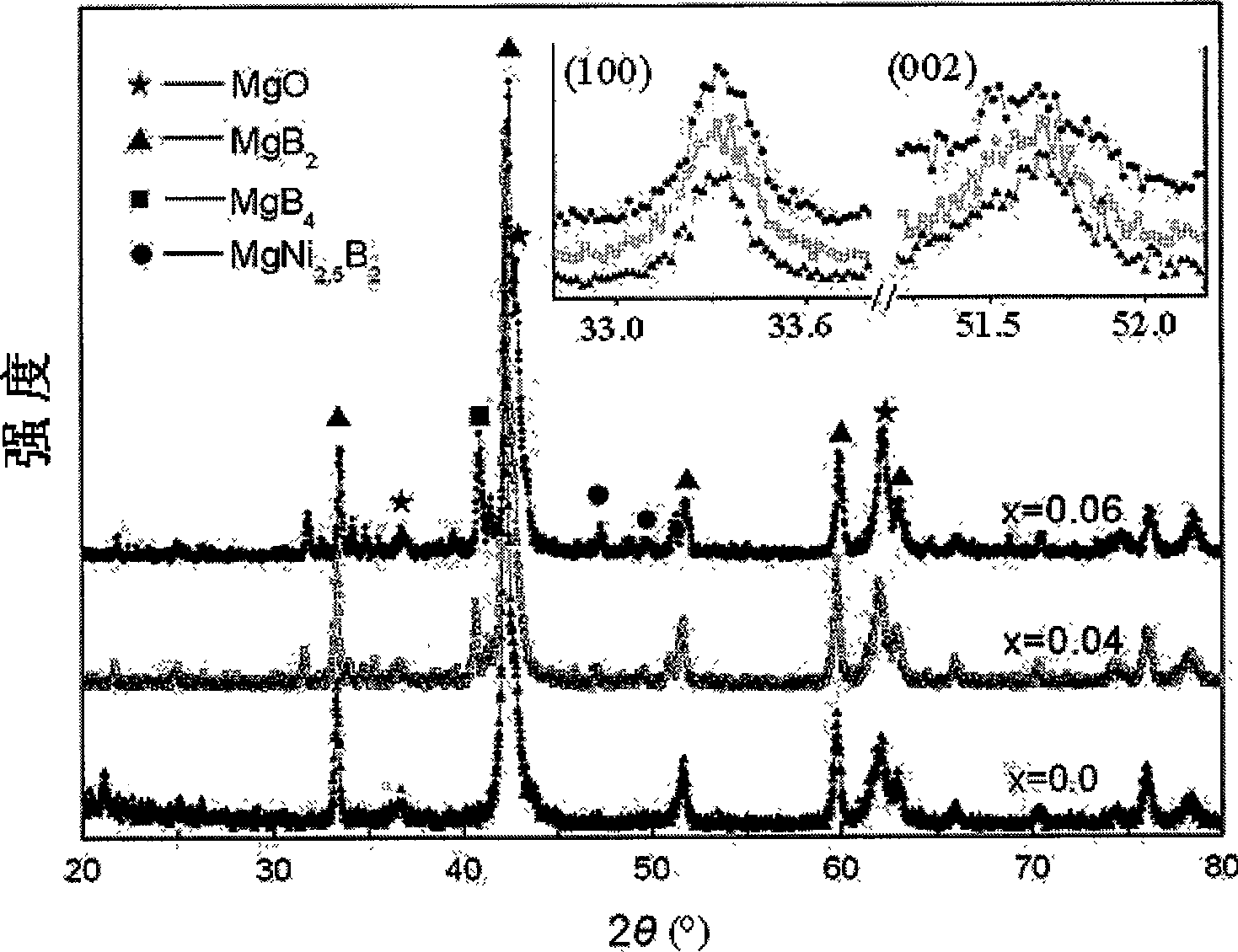

[0028] An in-situ preparation of nickel nanoparticles doped MgB 2 The method for superconducting material is made up of following steps: (1) takes by weighing respectively the amorphous boron powder (purity 99%) of 1.5 gram and the Ni (NO of 0.832 gram) 3 ) 2 ·6H 2O powder, then the powder is poured into the container, while pouring into distilled water equivalent to 50 times the weight of the raw material, the beaker is placed on a magnetic stirrer to stir, and titrated with NaOH solution, the reaction that occurs in this process is:

[0029] Ni(NO 3 ) 2 ·6H 2 O+2NaOH=Ni(OH) 2 (precipitation)+2NaNO 3 ;

[0030] After the titration, the beaker was placed at room temperature to precipitate for 3 hours, the precipitate was separated from the aqueous solution, the remaining aqueous solution was poured out, and the precipitated substance B and Ni(OH) 2 Dry in a desiccator to remove excess moisture,

[0031] (2) Put the dried powder into a tube furnace and calcinate at 300...

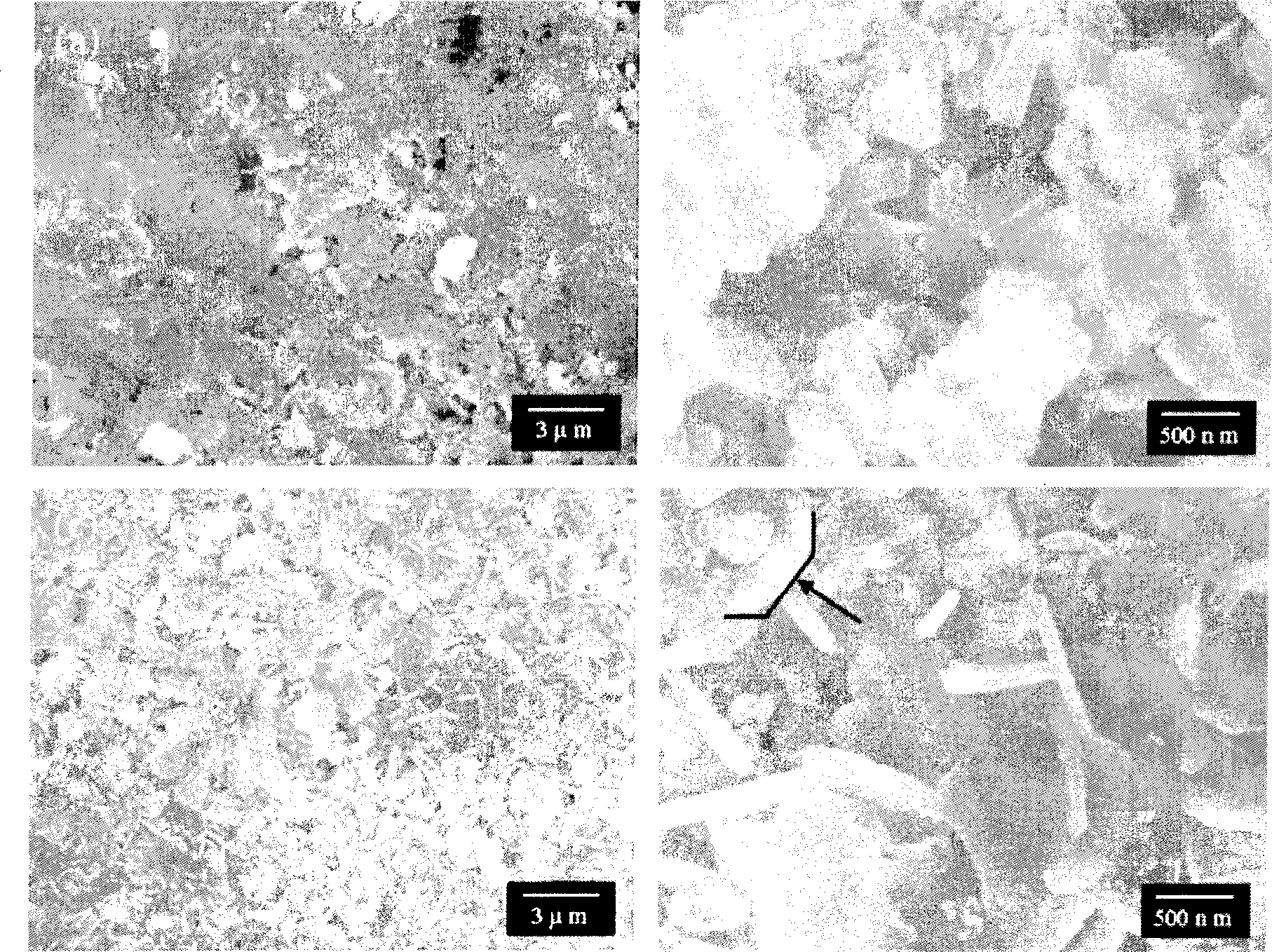

Embodiment 2

[0036] An in-situ preparation of carbon-coated nickel particles doped with MgB 2 The method for superconducting material is made up of the following steps: first the prepared raw material is pressed by Mg 0.95 Ni 0.05 B 2 Weigh magnesium powder (purity 99.5%), amorphous boron powder (purity 99%) and Ni(NO 3 ) 2 ·6H 2 O powder. Secondly, B powder and Ni(NO 3 ) 2 ·6H 2 Pour the O powder into a large beaker after weighing, and pour distilled water equivalent to 50 times the weight of the raw material at the same time, place the beaker in a magnetic stirrer to stir, and titrate with NaOH solution. After the titration, place the beaker at room temperature to precipitate 7 After one hour, separate the precipitate from the aqueous solution, pour out the remaining aqueous solution, dry the precipitate in a drying oven to remove excess water, put it in a tube furnace, and calcinate at 500°C for 3 hours under the protection of argon, and then Raise the temperature to 600°C and ...

Embodiment 3

[0038] An in-situ preparation of carbon-coated nickel particles doped with MgB 2 The method for superconducting material is made up of the following steps: first the prepared raw material is pressed by Mg 0.94 Ni 0.06 B 2 Weigh magnesium powder (purity 99.5%), amorphous boron powder (purity 99%) and Ni(NO 3 ) 2 ·6H 2 O powder. Secondly, B powder and Ni(NO 3 ) 2 ·6H 2 O powder is weighed and poured into a container, and at the same time, pour distilled water equivalent to 50 times the weight of the raw material, stir the beaker in a magnetic stirrer, and titrate with NaOH solution. After the titration, place the beaker at room temperature to precipitate 12 Hours later, separate the precipitate from the aqueous solution, pour out the remaining aqueous solution, dry the precipitate in a drying oven to remove excess water, put it in a tube furnace, and calcinate at 600°C for 5 hours under the protection of argon and then heat up to 700°C, pass H into the tube furnace 2 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com