Novel wave-absorbing material and preparation method thereof

A wave-absorbing material, a new type of technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of no fluorescence effect, high density of ferrite magnetic materials, and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Manganese-doped zinc sulfide precursor is prepared by hydrothermal method, the content of manganese ion in manganese-doped zinc sulfide is 7%, according to the molar ratio of manganese, zinc and sulfur in manganese-doped zinc sulfide, calculate and weigh zinc nitrate hexahydrate, acetic acid tetrahydrate Add manganese and thiourea, add additives, dissolve in twice distilled water, stir for 1 hour after dissolving, pour into a polytetrafluoroethylene-lined hydrothermal reaction kettle, react at 170 degrees Celsius for 13 hours, cool naturally to room temperature, and obtain a precipitate . The precipitate was filtered, fully washed with absolute ethanol and distilled water, and dried in a vacuum oven to obtain a solid powder, which was recorded as a precursor.

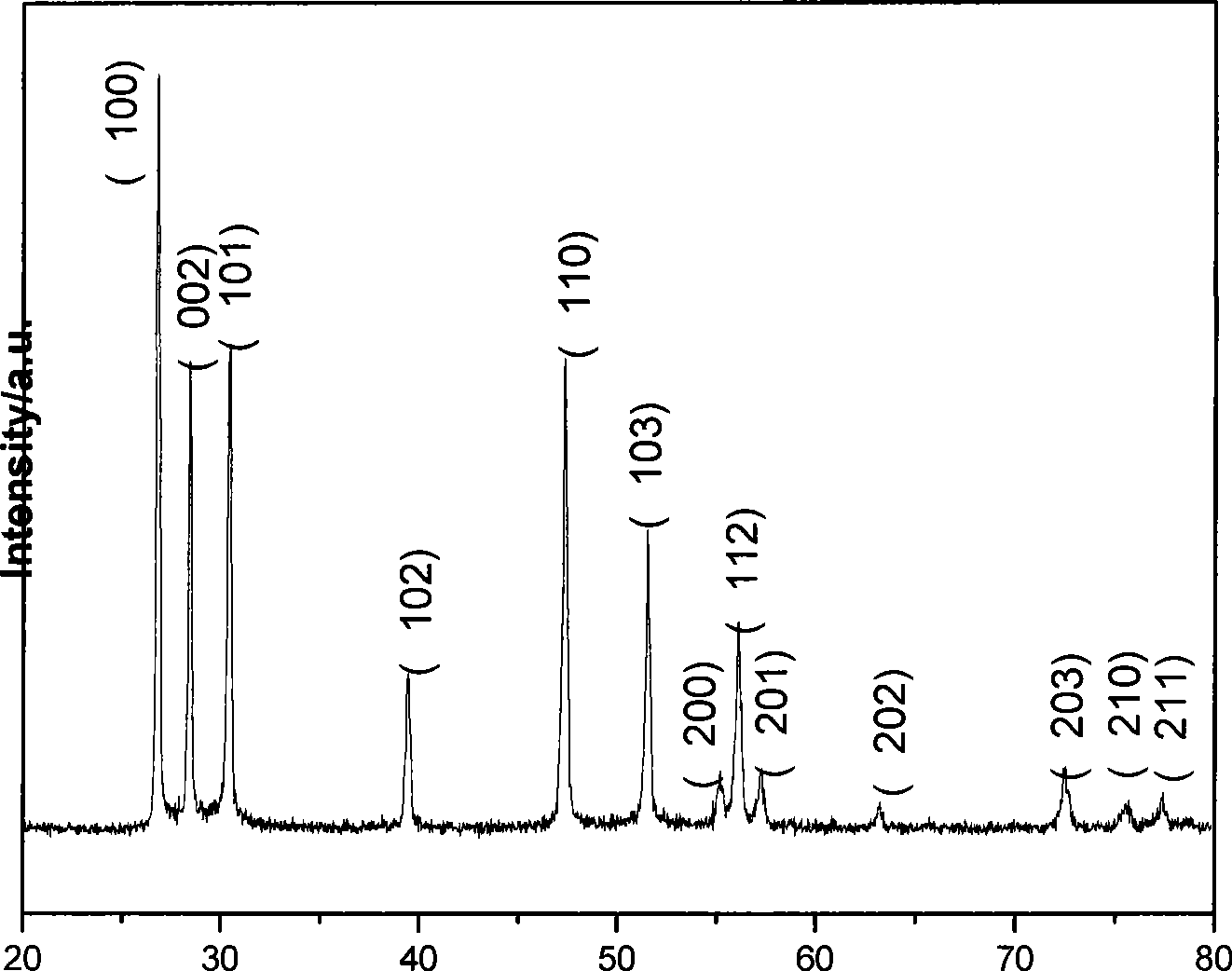

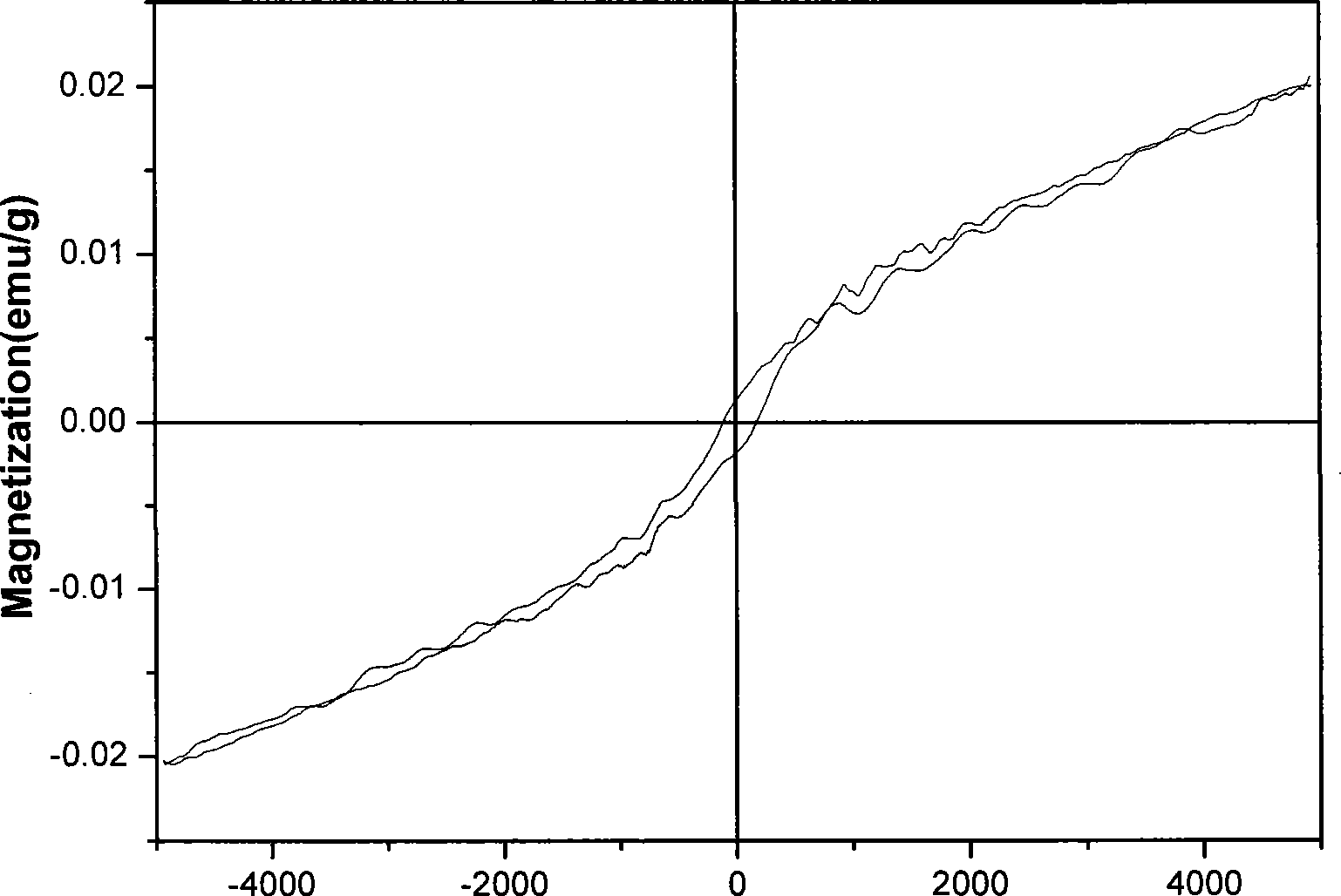

[0029] The precursor is put into a vacuum furnace, evacuated and filled with argon, and heat-treated at a constant temperature of 1050 degrees Celsius for a period of time to obtain a pure hexagonal phase mangane...

Embodiment 2

[0032] Manganese-doped zinc sulfide precursor is prepared by hydrothermal method, the content of manganese ion in manganese-doped zinc sulfide is 7%, according to the molar ratio of manganese, zinc and sulfur in manganese-doped zinc sulfide, calculate and weigh zinc nitrate hexahydrate, acetic acid tetrahydrate Add manganese and thiourea, add additives, dissolve in twice distilled water, stir for 1 hour after dissolving, pour into a polytetrafluoroethylene-lined hydrothermal reaction kettle, react at 170 degrees Celsius for 13 hours, cool naturally to room temperature, and obtain a precipitate . The precipitate was filtered, fully washed with absolute ethanol and distilled water, and dried in a vacuum oven to obtain a solid powder, which was recorded as a precursor.

[0033] The precursor is put into a vacuum furnace, evacuated and filled with argon, and subjected to constant temperature heat treatment at 650 degrees Celsius for a period of time to obtain pure cubic phase mang...

Embodiment 3

[0036] Put the precursor into a vacuum furnace, vacuum and fill with nitrogen. All the other are with embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com