Emulsion polymerizing preparation method of polyethylene/silicon dioxide core-shell structure composite material

A technology of silicon dioxide and composite materials, applied in the field of composite materials, can solve the problems of weak chemical action, unable to obtain polyethylene/silica shell-core structure composite materials, unstable nanoparticles, etc., and achieve the effect of high surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

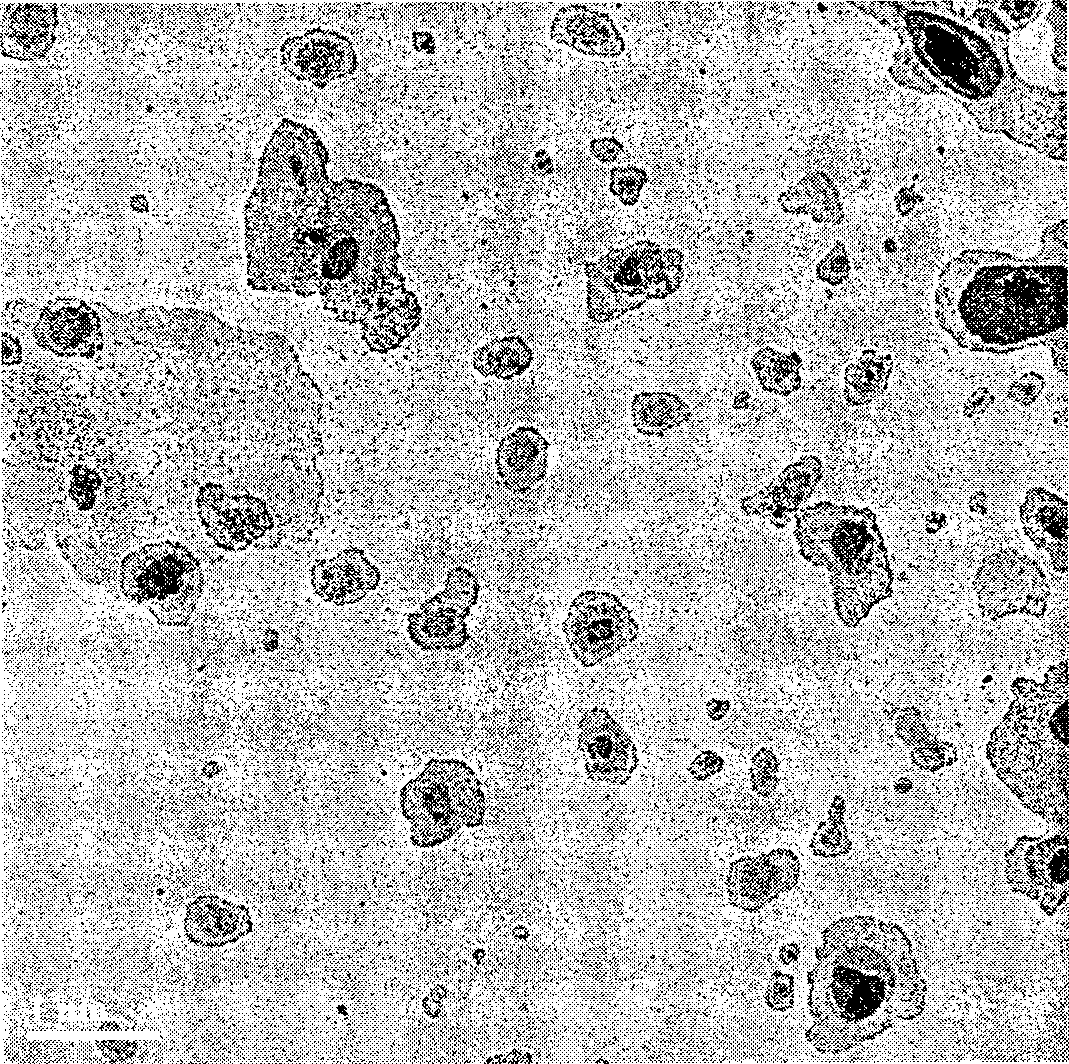

Image

Examples

Embodiment 1

[0022] Take 0.1 g of vinyl-functionalized mesoporous silica nanoparticles with 0.1 mmol of bis-(cyclooctyl-1,5-diene)nickel and 0.1 mmol of ethyl 4,4,4-trifluoro-2- (Triphenylphosphine ylide)-acetyl ethyl ester mixed;

[0023] Add 0.5 ml of toluene, stir for 20 minutes, and disperse in 100 ml of water;

[0024] Add 1 gram of sodium lauryl sulfate and sonicate for 1 minute;

[0025] The dispersed emulsion was transferred to an autoclave, and ethylene gas was introduced into it. The ethylene gas was maintained at a pressure of 50 atmospheres, and the temperature was raised to 60 degrees Celsius, stirred, and reacted for 2 hours to obtain a polyethylene / silicon dioxide emulsion. After the polyethylene / silicon dioxide emulsion is dried, it is annealed at 130 degrees centigrade to obtain a polyethylene / silicon dioxide shell-core composite material with an inorganic component content of 1.2%.

Embodiment 2

[0027] Take 0.2 g of vinyl-functionalized mesoporous silica nanoparticles with 0.3 mmol of bis-(cyclooctyl-1,5-diene)nickel and 0.3 mmol of ethyl 4,4,4-trifluoro-2- (Triphenylphosphine ylide)-acetyl ethyl ester mixed;

[0028] Add 2 ml of toluene, stir for 20 minutes, and disperse in 400 ml of water;

[0029] Add 1 gram of sodium lauryl sulfate and 1 gram of dodecyltrimethylammonium chloride, and sonicate for 2 minutes;

[0030] The dispersed emulsion was transferred to an autoclave, and ethylene gas was introduced into it. The ethylene gas was maintained at a pressure of 10 atmospheres, the temperature was raised to 70 degrees Celsius, stirred, and reacted for 3 hours to obtain a polyethylene / silicon dioxide emulsion. After the polyethylene / silicon dioxide emulsion is dried, it is annealed at 130 degrees centigrade to obtain a polyethylene / silicon dioxide shell-core composite material with an inorganic component content of 2.8%.

Embodiment 3

[0032] Take 0.4 g of vinyl-functionalized mesoporous silica nanoparticles with 0.5 mmol of bis-(cyclooctyl-1,5-diene)nickel and 0.5 mmol of ethyl 4,4,4-trifluoro-2- (Triphenylphosphine ylide)-acetyl ethyl ester mixed;

[0033] Add 4 ml of benzene, stir for 20 minutes, and disperse in 1000 ml of water;

[0034] Add 2 grams of sodium lauryl sulfate and 2 grams of cetyltrimethylammonium bromide, and sonicate for 3 minutes;

[0035] The dispersed emulsion was transferred to an autoclave, and ethylene gas was introduced into it. The ethylene gas was maintained at a pressure of 30 atmospheres, the temperature was raised to 50 degrees Celsius, stirred, and reacted for 4 hours to obtain a polyethylene / silicon dioxide emulsion. After the polyethylene / silicon dioxide emulsion is dried, it is annealed at 130 degrees centigrade to obtain a polyethylene / silicon dioxide shell-core composite material with an inorganic component content of 1.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com