Mesoporous carbon immobilized enzyme biological sensing material doped with nitrogen and preparing method thereof

A nitrogen-doped mesoporous carbon, immobilized enzyme technology, applied in the fields of biocatalysis and biosensing, can solve the problem of poor biocompatibility of mesoporous carbon materials, unsuitable for large biomolecular loads, and small pore size of mesoporous carbons. and other problems, to achieve the effect of environmental friendliness, strong practicability and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

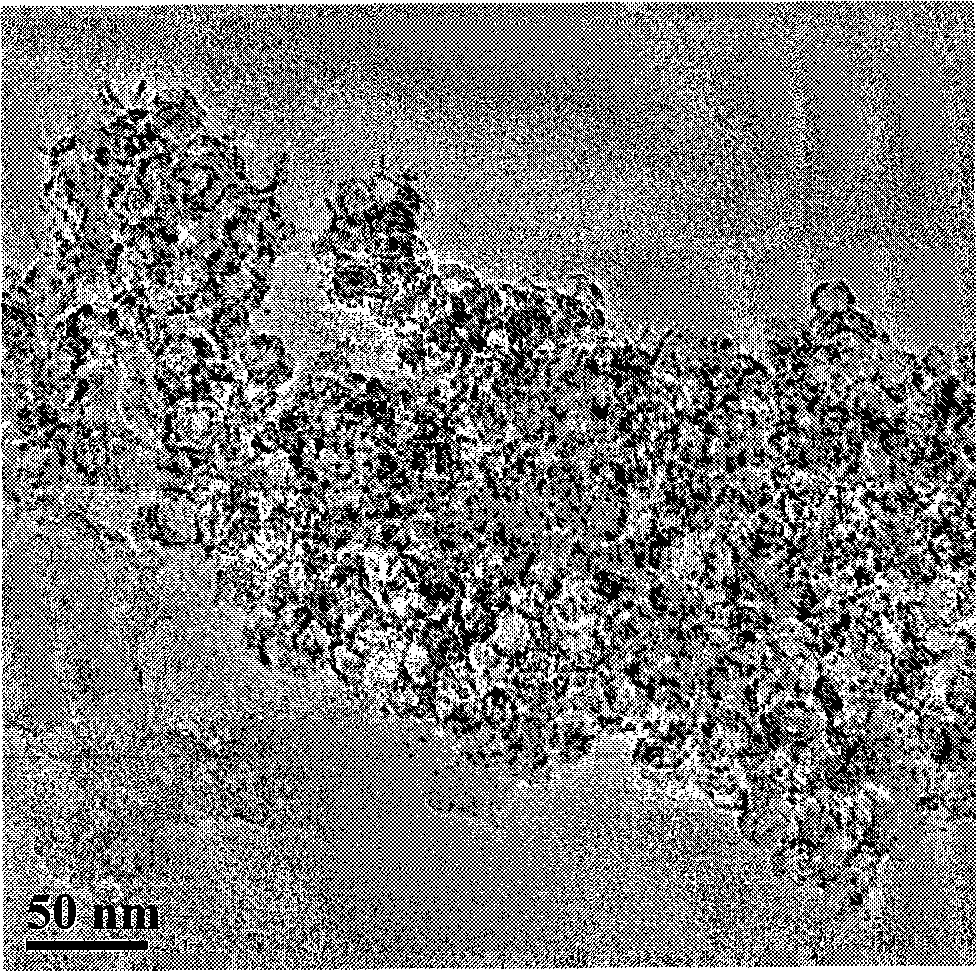

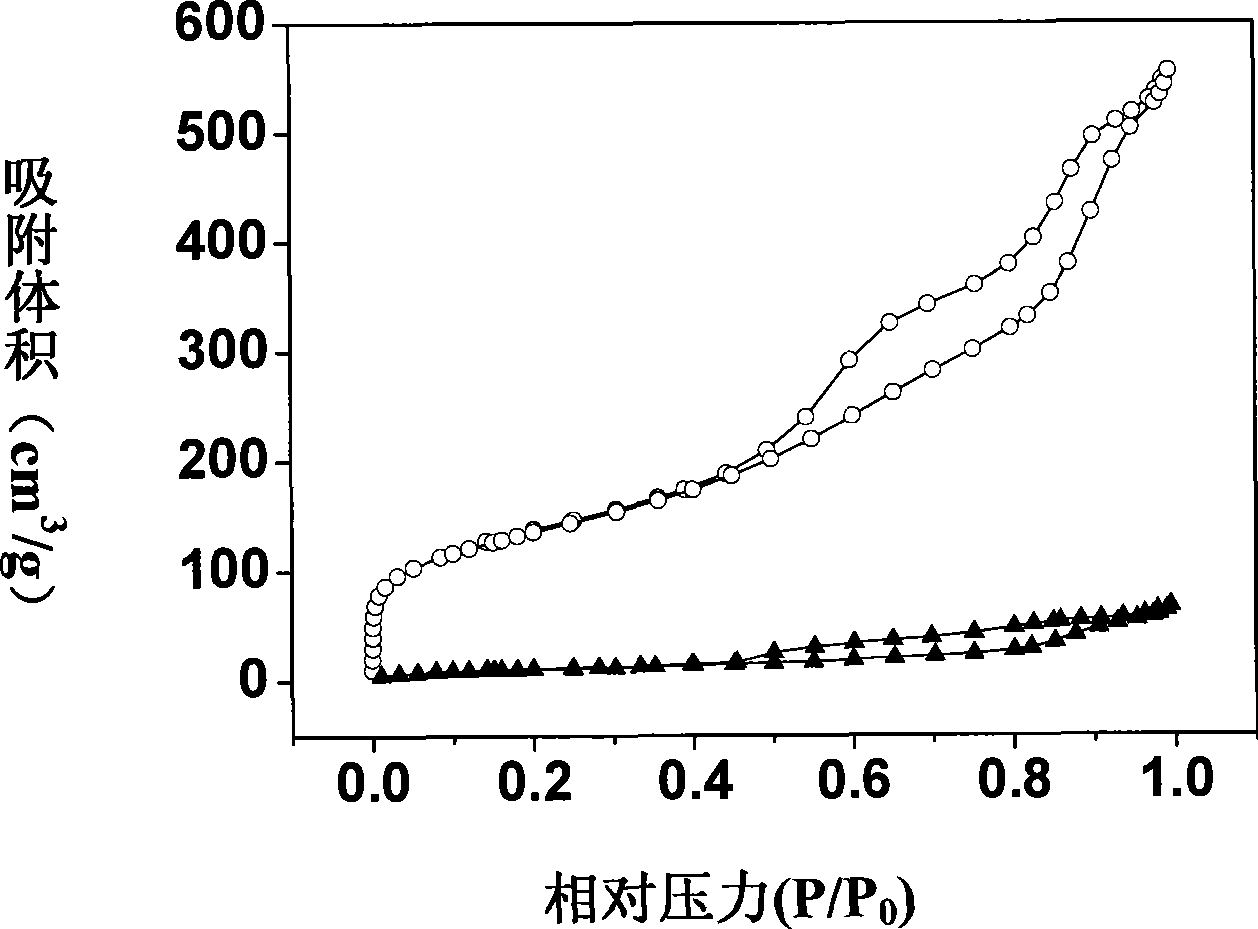

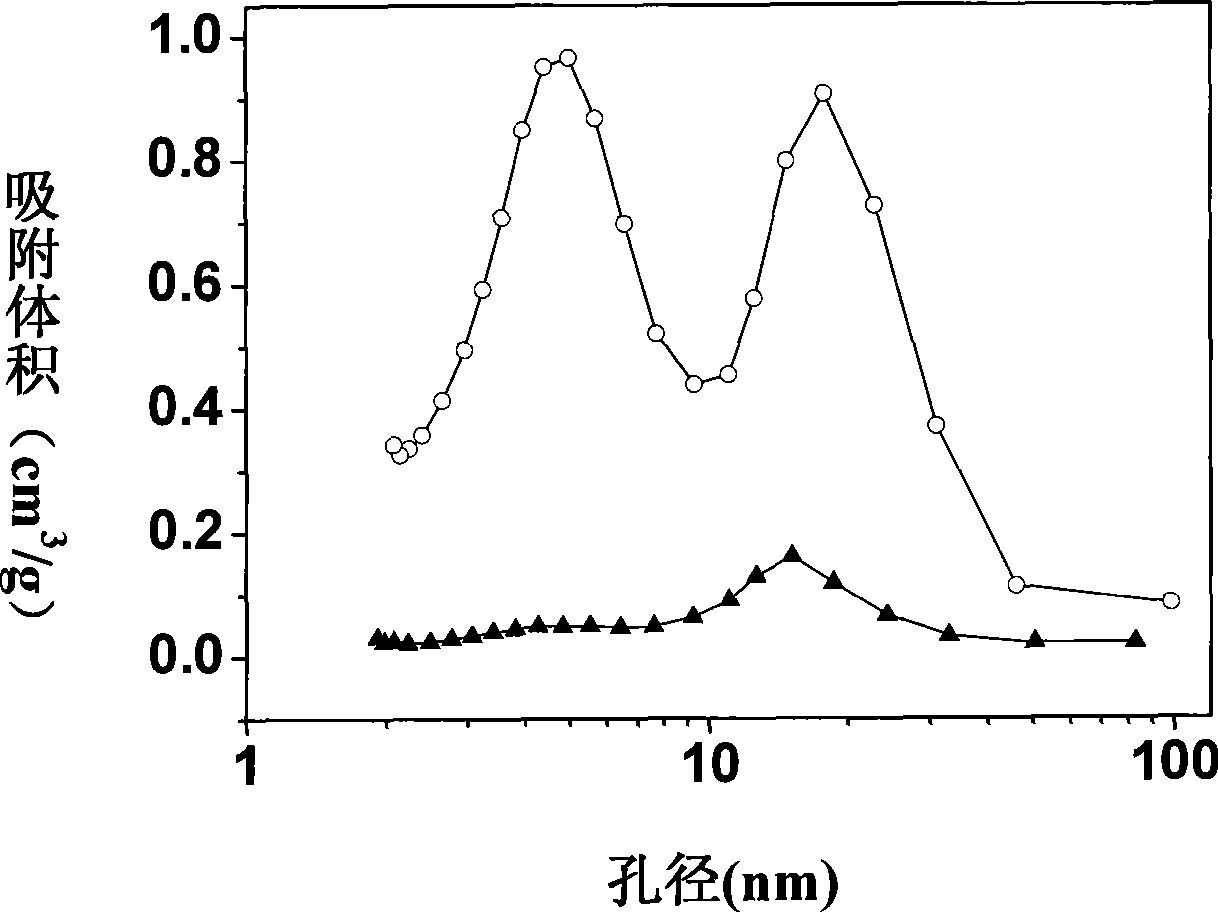

[0029] Accurately measure 2.4ml of ethylenediamine and 3.4ml of carbon tetrachloride, mix well, add 0.5g of MCF template, reflux at 90°C for 6 hours, then transfer to an oven to dry for 12 hours, the obtained solid is finely ground with a mortar, and then Carbonization was carried out at 600° C. for 5 hours in a nitrogen atmosphere. The resulting carbide was treated with 10% HF solution to remove the silicon template. The nitrogen adsorption curve and pore size distribution of the obtained nitrogen-doped mesoporous carbon are as follows: figure 1 and figure 2 As shown, its specific surface area and pore volume are 474m 2 g- 1 and 0.85cm 3 g -1 , the pore size is about 17nm obtained from the adsorption curve.

[0030] Weigh 80 mg of the obtained nitrogen-doped mesoporous carbon, put it into 4 ml of 20% nitric acid, react at 60° C. for 6 h for modification, filter, wash and dry.

[0031] Weigh 10 mg of the above-mentioned modified nitrogen-doped mesoporous carbon, add to...

Embodiment 2

[0037] The pyrolytic graphite electrode was sanded smooth on sandpaper, sonicated in deionized water for 10 min, and removed to dry. Then take 10 mg of the immobilized enzyme obtained in Example 1, disperse it in 2 ml of 5wt% Nafion phosphate buffer solution, take 0.5 ml, evenly drop-coat it on the pyrolytic graphite electrode, dry it at room temperature to form a film, and form a biosensor for electrochemical determination.

[0038] The electrochemical determination was carried out on a CHI 440 electrochemical workstation, using a three-electrode system, in which the graphite electrode was used as the working electrode, the platinum wire was used as the counter electrode, and Ag / AgCl was used as the reference electrode. The cyclic voltammogram of the prepared enzyme sensor is as follows: Figure 4 As shown, the appearance of a pair of reversible redox peaks indicates that the enzyme sensor can realize direct electron transfer between the enzyme and the electrode, and its ele...

Embodiment 3

[0042] In Example 2, other experimental methods and preparation steps remained unchanged, except that 10 mg of the immobilized enzyme in Example 1 was dispersed in 4 ml of 5 wt% Nafion phosphate buffer solution, and then 0.5 ml was used to prepare the biosensor. The response time of the enzyme sensor is also less than 5 seconds, and the linear range is 1-80 μmol. The curve of its current response value to the concentration of hydrogen peroxide is as follows Figure 5 As shown, the calculated sensitivity of the enzyme sensor is 142mA L mol -1 cm- 2 , all lower than those in Example 2 and Comparative Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com