Streptomyces clavuligerus, as well as preparation method and application thereof

A technology of Streptomyces coryneformis and strains, applied in the field of biopharmaceuticals, can solve the problems of low production of clavulanic acid, etc., and achieve the effects of short cycle, strong purpose and low work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

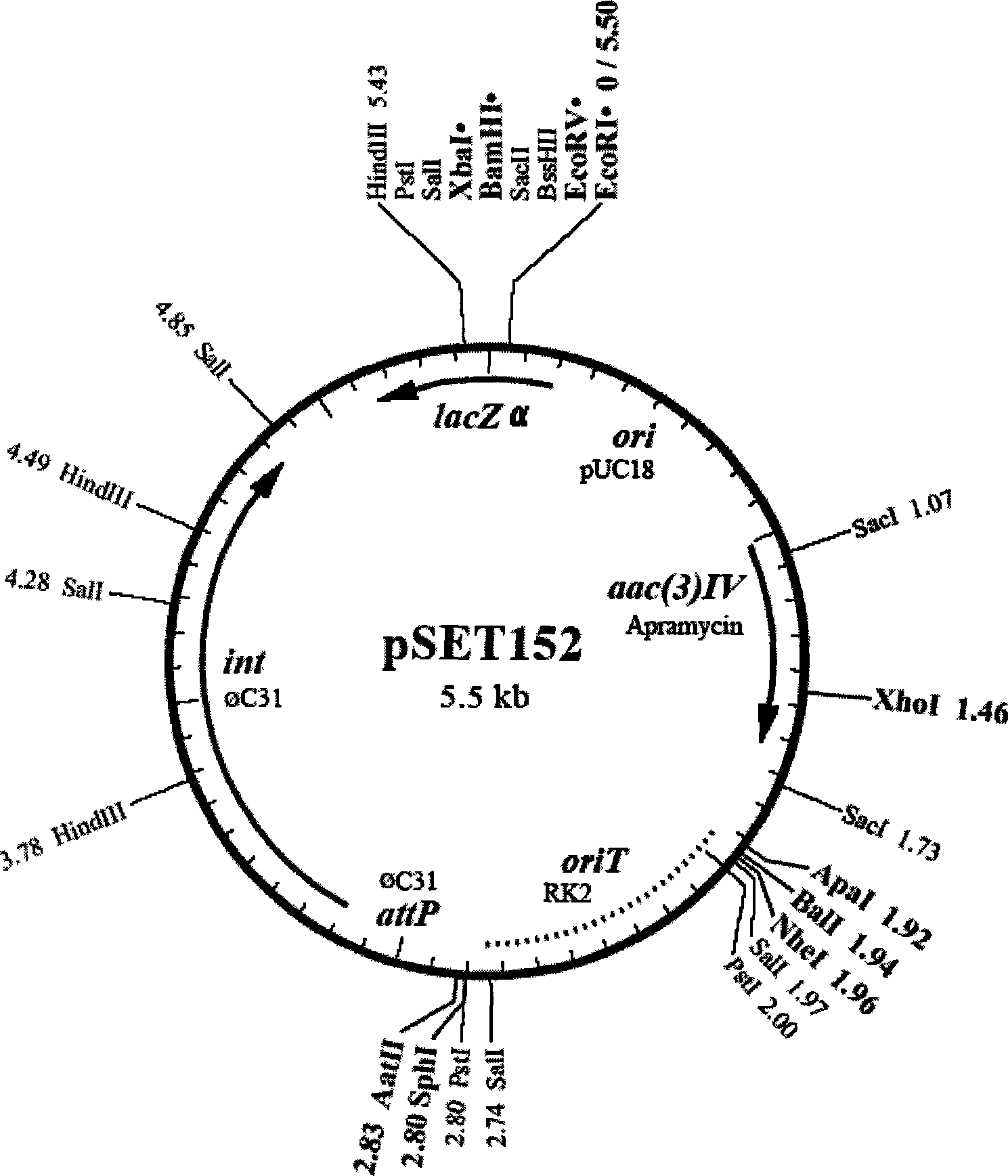

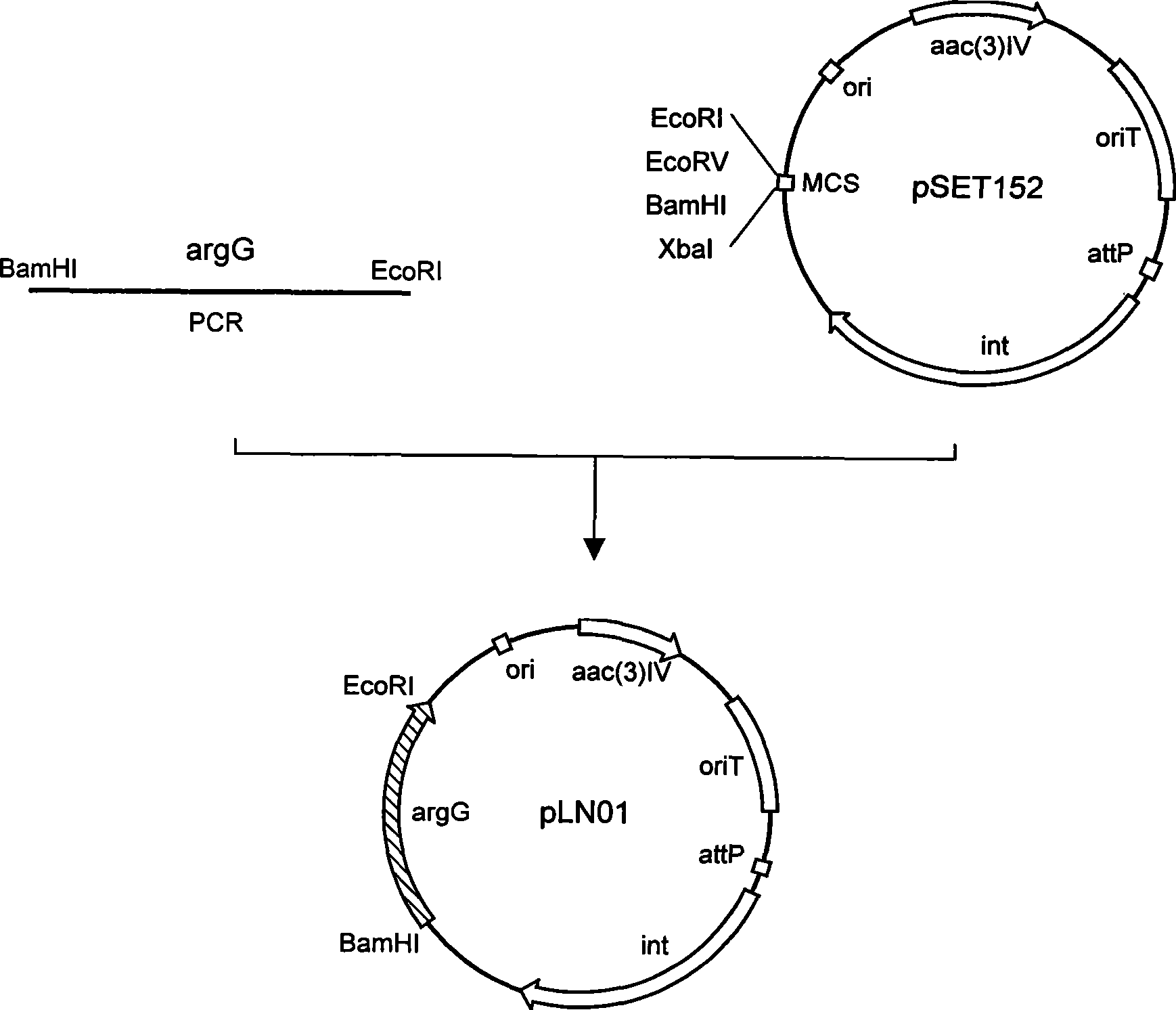

[0032] Example 1 Construction of argG gene insertion vector

[0033] Primers were designed according to the DNA sequence of the Streptomyces clavuligerus (Streptomyces clavuligerus) argG gene (Z49111), and the argG gene fragment was amplified in vitro by PCR using the total DNA of Streptomyces clavuligerus, and the PCR product was purified, and then detected by electrophoresis (accompanying drawing 4 ).

[0034] According to the analysis of Streptomyces clavulatus encoding argG gene sequence, two primers for PCR amplification argG gene were designed, respectively as follows:

[0035] argG-up: CGCGGATCCCGTAAGCGTCCGATCACTTCG

[0036] argG-down: CCGGAATTCGCTGCTCACTGCGGGAACT

[0037] The PCR product was double-digested with BamHI and EcoRI, and then inserted into the same double-digested pSET152 plasmid (Figure 2). Positive clones were obtained through blue-white screening, and the plasmid was extracted, verified by BamHI and EcoRI double-digestion, and electrophoresis to detect...

Embodiment 2

[0038] The preparation of embodiment 2 Streptomyces protoplasts

[0039] Protoplast selection of transformed strains

[0040] Add 100ml YEME+TSBY (1:1) and 0.2% glycine to a 250ml Erlenmeyer flask equipped with a stainless steel spring, inoculate 100ul of spore suspension, and incubate at 30°C at 200rpm for 36h-40h. Then the mycelium was collected, and the collected mycelium was washed with 10.3% sucrose solution for three times, and the mycelium was collected by centrifugation at 3000 rpm for 10 min. Take the mycelium, add the P buffer of lysozyme, and put it in a water bath at 30°C for 30-60min until the supernatant becomes milky. Filter with a test tube equipped with absorbent cotton, transfer the filtrate into a sterile universal, and centrifuge at 3000rpm for 7min to collect the protoplast precipitate, which is yellow. Gently break up the protoplasts, wash with P buffer to remove lysozyme, centrifuge under the same conditions, collect the protoplasts, remove the superna...

Embodiment 3

[0043] Embodiment 3 Shake flask detection of genetically engineered bacteria

[0044] Shake flask experiments were carried out on the screened engineered bacteria to detect their ability to produce clavulanic acid. The original strain was used as the control strain, soybean medium was selected as the fermentation medium, the liquid volume of the shake flask was 1:10, the inoculum volume was 5%, cultured at 28°C, 250rpm, samples were taken at different times to detect the content of clavulanic acid . Each experiment had two repetitions. The results of HPLC detection showed that compared with the original strain, the output of Streptomyces clavulatus LNSC-02 had been greatly improved, which was increased by 20% at 72 hours (accompanying drawing 5, accompanying drawing 6).

[0045] Table 1 The content of clavulanic acid in the fermentation broth detected by HPLC

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com