Ultraviolet light crosslinked EPT rubber cable insulation material and preparation thereof

A technology for EPDM rubber and cable insulation, which is applied in the direction of rubber insulators, insulated conductors, and insulated cables, can solve the problems that EPDM rubber is difficult to talk about and cannot be applied, and achieves simple cross-linking process, low product cost, The effect of low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]100 parts of E-type EPDM, 40 parts of calcium carbonate, 60 parts of talcum powder, 0.8 part of BDK, 1 part of TMPTA, 5 parts of paraffin oil, 0.8 part of silane coupling agent KH570, antioxidant 0.2 parts of 1010, 0.1 parts of DLTP, mixed at 100-150°C for 8-10 minutes, and then extruded into sheets through a twin-screw extruder to obtain light-crosslinked EPDM cable materials; The conductive core of the cable is melt-extruded and coated with the cable material to form an insulating layer, and then it is heated at a wavelength of 200-400nm and a light intensity of 400-2000mW / cm 2 Under the ultraviolet light source, the insulating layer is cross-linked by ultraviolet light irradiation.

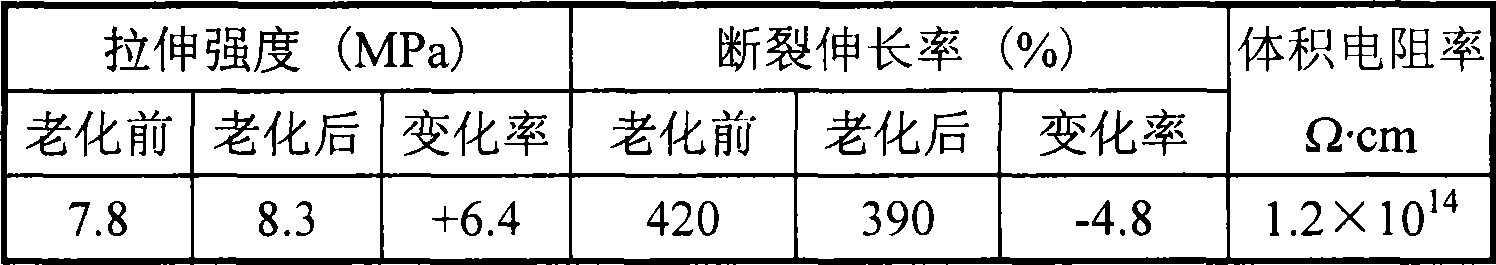

[0025] The detection data of the ultraviolet light cross-linked EPDM cable material properties prepared by this example are as follows:

[0026]

[0027] *Heat aging condition: 135±2℃×168 hours.

Embodiment 2

[0029] Put 100 parts of E-type EPDM into the internal mixer by weight, 30 parts of nanometer calcium carbonate, 30 parts of talcum powder, 60 parts of pottery clay, 1.5 parts of BP, 1.5 parts of TAIC, 5 parts of paraffin oil, 0.8 part of silane coupling agent KH570 , 0.2 part of antioxidant 1010, 0.1 part of DLTP, mixed uniformly at 100-150 ° C and extruded into flakes, other operations were the same as in Example 1.

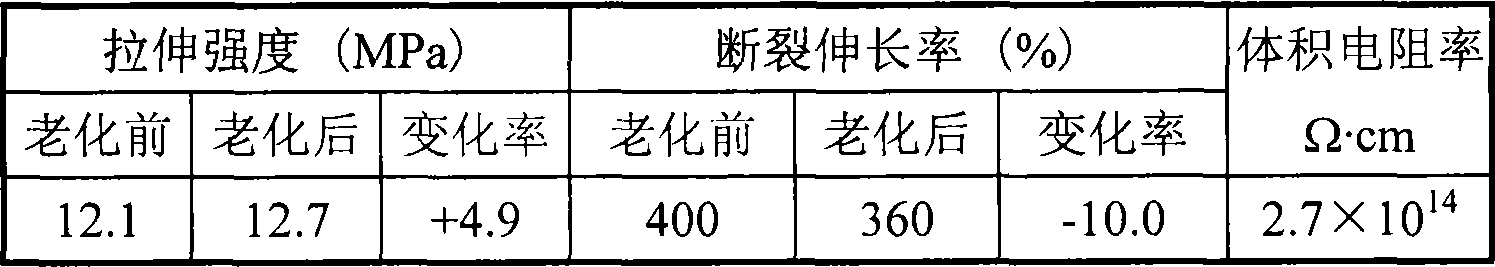

[0030] The detection data of the ultraviolet light cross-linked EPDM cable material properties prepared by this example are as follows:

[0031]

[0032] *Heat aging condition: 135±2℃×168 hours.

Embodiment 3

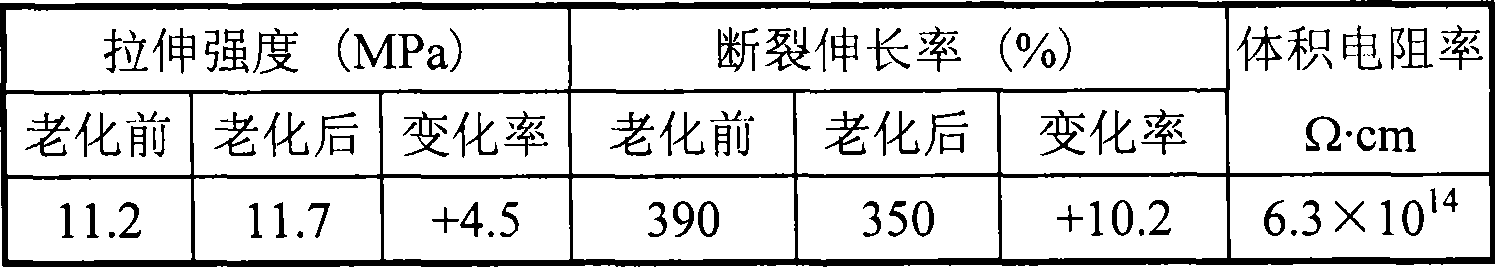

[0034] Put 100 parts of E-type EPDM, 50 parts of talcum powder, 70 parts of calcined clay, 1.2 parts of BDK, 0.8 parts of BP, 3 parts of TAIC, 5 parts of paraffin oil, and 1 part of silane coupling agent KH550 into the internal mixer by weight , 0.6 parts of antioxidant 168, 0.3 parts of DTDTP, mixed uniformly at 100-150 ° C and extruded into flakes, other operations are the same as in Example 1. The detection data of the ultraviolet light cross-linked EPDM cable material properties prepared by this example are as follows:

[0035]

[0036] *Heat aging condition: 135±2℃×168 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com