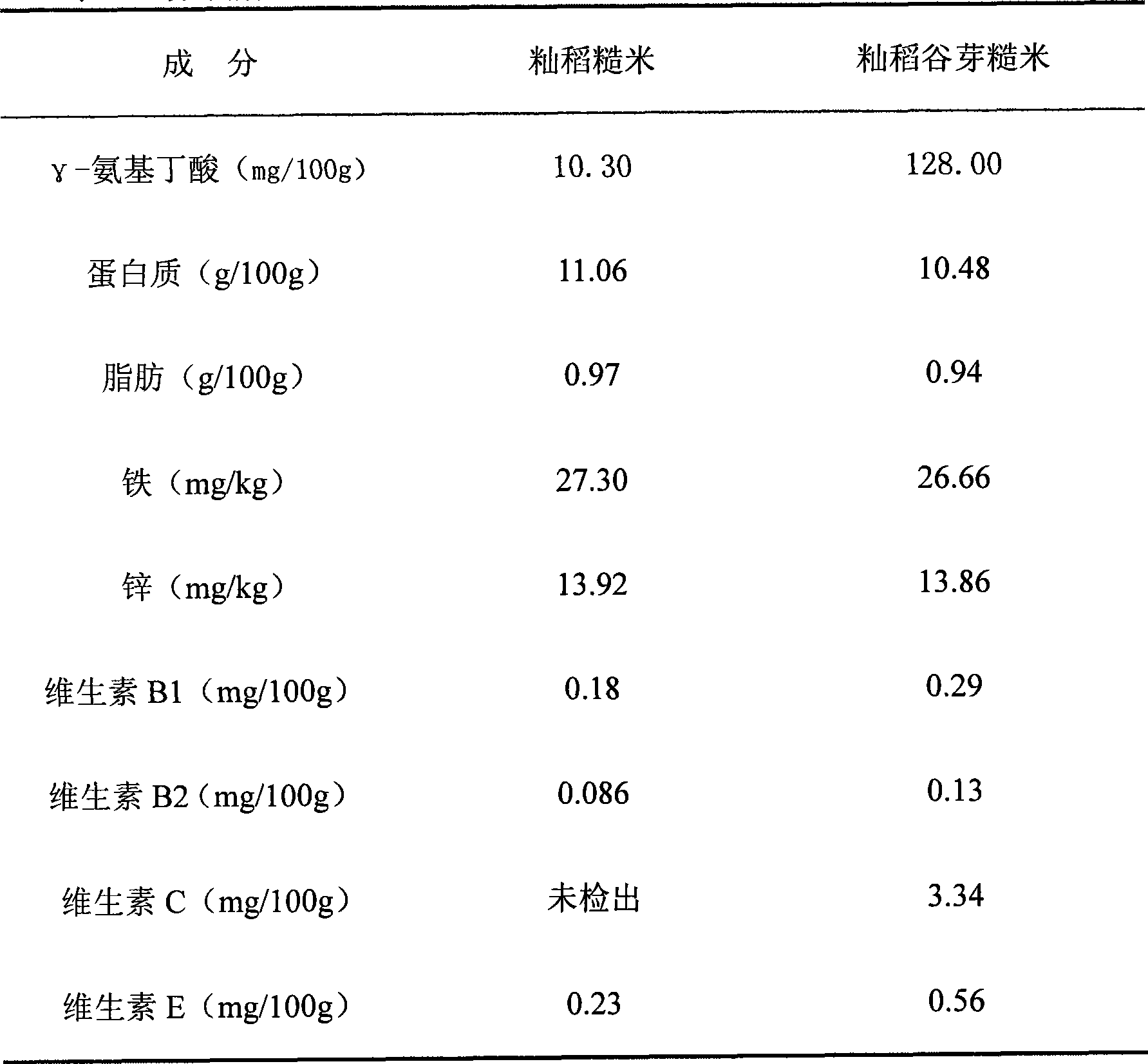

Husked indica-type rice with sprout rich in gamma-aminobutyric acid and preparation method thereof

An aminobutyric acid and germination technology, applied in the field of germinated brown rice and its preparation, can solve the problems of aflatoxin production, unsafe germinated rice, and increased product cost, so as to promote production, not easy to ferment, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

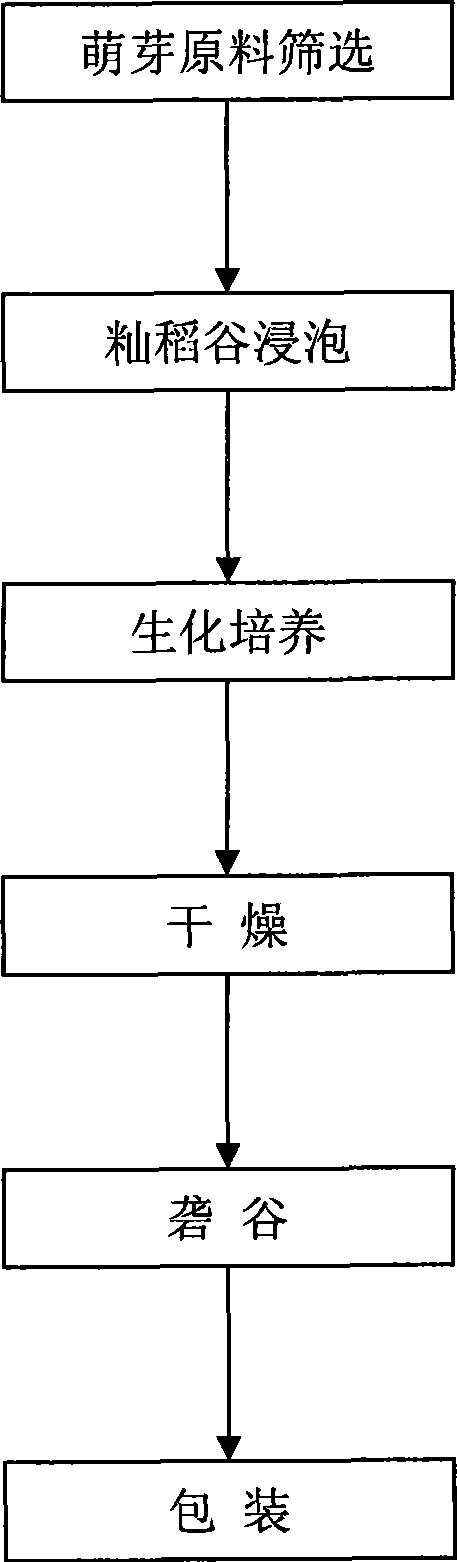

Method used

Image

Examples

Embodiment 1

[0033] (1) Using indica rice as raw material, immerse in a calcium gluconate solution with a concentration of 0.25mmol / L and a temperature of 25°C for 26h;

[0034] (2) Germinate and cultivate the obtained soaked indica rice at 28° C. for 25 h in a biochemical incubator;

[0035] (3) placing the germinated indica rice obtained after biochemical cultivation in a hot air drying oven at 40° C. for 8 hours to obtain germinated indica rice;

[0036] (4) hulling the obtained germinated indica rice to obtain brown rice of germinated indica rice.

[0037] (5) Carry out vacuum packaging to the germinated brown rice of indica rice.

Embodiment 2

[0039] (1) Using the indica rice 168-4 sold in the Wuhan rice variety market as a raw material, immerse it in a calcium gluconate solution with a concentration of 0.3mmol / L and a temperature of 25°C for 24h;

[0040] (2) Germinate and cultivate the soaked indica rice obtained for 30 h at 25° C. in a biochemical incubator;

[0041] (3) placing the germinated indica rice obtained after biochemical cultivation in a hot air drying oven at 45° C. for 6 hours to obtain germinated indica rice;

[0042] (4) hulling the obtained germinated indica rice to obtain brown rice of germinated indica rice.

[0043] (5) Carry out vacuum packaging to the germinated brown rice of indica rice.

Embodiment 3

[0045] (1) Indica rice 168-4 sold in the rice variety market in Wuhan was used as raw material, soaked in a calcium gluconate solution with a concentration of 0.5 mmol / L and a temperature of 32°C for 22 hours.

[0046] (2) The obtained soaked indica rice was germinated and cultured for 20 h at 35° C. in a biochemical incubator.

[0047] (3) The germinated indica rice obtained after the biochemical cultivation was placed in a hot air drying oven at 35° C. for 9 hours to dry to obtain the germinated indica rice.

[0048] (4) hulling the obtained germinated indica rice to obtain brown rice of germinated indica rice.

[0049] (5) Carry out vacuum packaging to the germinated brown rice of indica rice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com